It is however true that agriculture is still largely non-automated and non-digitized. This has been mainly because the technological deficiencies have so far held back automation. This is, however, changing, largely (but not exclusively) thanks to leaps in two core technologies: (a) CNN-based machine vision and (b) autonomous mobility.

These technologies are enabling completely new product categories, new methods of farming, and even new business models. Despite the vanishingly small penetration of such technologies today, IDTechEx Research assesses that agricultural robots and AI-based machine vision represent the natural evolution of agricultural machines and tools.

Naturally, many companies – large and small- are actively pursuing the new commercial opportunities that technologies enable. This explores the latest technical and development trends, particularly focusing on assessing the readiness level of various companies and product categories/types.

The content of this article is drawn from the latest research from IDTechEx, Agricultural Robots, Drones, and AI: 2020-2040: Technologies, Markets, and Players, which offers a deep and comprehensive analysis of all technologies, companies and markets in agricultural robots, drones, and AI.

This report analyses all the emerging product types including autonomous robots taking plant-specific precision action, intelligent vision-enabled robotic implements, diverse robotic fresh fruit harvesters, highly automated and autonomous tractors and high-power farm vehicles, drones, automatic milking, and so on. It provides interview-based company profiles and analysis of all the key companies and innovators.

Finally, the report offers short- and long-term market forecasts, considering the addressable market size in area/tons and value, penetration rates, annual robot sales, accumulated fleet size, total RaaS (robot as a service) revenue projections and so on. The forecasts cover 15 robot types and farming sectors.

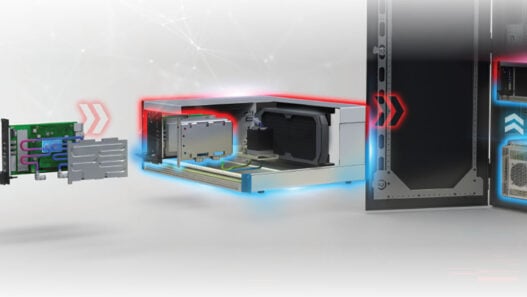

The image above shows the technical readiness level of various companies and products. Note that the color coding signals the type of robotic system. Clearly, many companies and product categories are in the system-subsystem development phase, whilst some have already reach technology readiness levels of nine to ten. This distribution of companies and products across the technology readiness spectrum signals that the industry has advanced, further nearing market readiness.

Autonomous ultraprecision robots

First let us consider those in blue, i.e., small/mid-sized ultraprecision robots. These are often small or mid-sized robots designed to autonomously navigate and to automatically take some ultraprecise plant-specific action. The CNN-based machine vision technology enables the robots to identify and localize individual plants. The first application is in precision weeding, promising to save chemicals, boost yield, and reduce soil compaction. In the future, this technology will allow the robots to analyze the health status and the growth conditions of each plant. The robots can take a site-specific precision action tailored to the needs of the individual plants.

At first, these robots are mainly targeting row vegetables, but in the future their tasks will become more diverse, encompassing all farm management activities. They are often (but not always) autonomous and, in many cases, electrically driven. The former enables the realization of swarms or large fleets of small robots. These robots are in some instances sold as equipment and in many cases are offered as a service (RaaS).

Some companies have already gone through multiple product iterations (see image panel below). In fact, some firms also have a widened product portfolio, positioning their older and smaller robots as, for example, data scouts.

In general, the key product development trends are the following: (1) improving the precision, recall, and speed of the algorithm on a specific plant/weed; (2) streamlining the process of data collection, annotation, and the training of the algorithms to extend the applicability of the robot to multiple plants; (3) making the robots larger so that they can have more onboard energy to support a longer operation time and a heavy load and so that they can cover more ha/day; and (4) ruggedizing the systems so that they can operate within an agricultural environment with minimal or no expert intervention.

In terms of commercial development, the emphasis has been on accumulating real-world experience. This is critical because the feedback enables the hardware design to evolve and to be perfected. Furthermore, operational time translates into more data which improves the algorithms. To accelerate deployment, many are offering their robots as a service even if it means that they remain a loss-making operation today.

Intelligent robotic implement

Next, let us consider intelligent robotic tractor-pulled implements. These implements are a far cry from purely mechanical implements commonly found today. Instead, they include many cameras and GPUs. Essentially, they are multiple full computer vision systems on wheels. The computer vision- just as was the case with small/mid-sized ultraprecision robots- enables the robot to see and to take precision action.

This technology has already evolved over the past five to seven years. This is shown in the images below. The target market here is large farms. Therefore, productivity is critical. Indeed, the pursuit of higher productivity can be seen in how the system has evolved from its early prototypes. Today, the latest versions can travel at 12mph and process the images at 20fps whilst maintaining a two inch resolution. The system is scaled to cover 12 rows.

Autonomous spraying vehicles

Autonomous orchard spraying vehicles are already in operation. They bring many benefits: (1) ability to spray during very early mornings or very late nights to avoid evaporation; (2) maintaining a constant travel and spray speed to achieve uniformity; (3) relieving staffing pressure/costs and reducing exposure to legal claims for exposure to chemicals; and so on. Interestingly, the leading companies here are those who already provide orchard spraying service. They, therefore, knows the business needs.

The navigational autonomy cannot be achieved with only RTK-GPS since the robot needs to navigate in GPS-poor/denied orchards and to distinguish between real roadblocks and those through which it can drive. Given the level of maturity and the legislative requirements, there is still a remote operator sitting in a pick-up truck at the edge of the farm. Nonetheless, the technical barriers are relatively low given that there is little advanced machine vision technology. This is reflected in their advanced technology readiness level. Nota that these vehicles are diesel-powered given that they require the horsepower for spraying the chemicals.

Highly automated or autonomous tractors

Thanks to RTK-GPS, tractors have long been benefiting from tractor guidance and autosteer. The latter is in fact level-4 autonomy since the tractor can autonomously drive outdoors along pre-determined GPS coordinates without human intervention.

Level-5 or fully autonomous tractors have also been demonstrated for some years. The technical barrier here is low. The additional cost incurred in going from level-4 to level-5, however, does not currently justify the additional benefits. This is because level-5 does will not enable many new possibilities until more tasks beyond just movement become automated.

Robotic fresh fruit harvesting

Multiple companies have been formed over the past five years or so to tackle the hitherto unsolved challenge of automating fresh fruit picking (apple, strawberry, grape, pear, etc). Some have decided to build autonomous mobility into their system. Most however have decided to focus purely on the main fresh fruit picking task. The products- as can be seen in the image panel below- have dramatically evolved, going from basic laboratory prototypes to large-scaled robust field machines.

The directions of product development have been the following: (1) improving the algorithm mainly using CNN techniques to cut down picking time; (2) extending the algorithms to recognize even more fruits so that the robot can be deployed across the entire calendar year; (3) designing novel end effectors to enable the gentle picking of the fruits; (4) selecting the right robotic arm (articulated vs delta) with the right performance-cost balance; (5) increasing the number of arms to boost productivity; (6) ruggedising the system for the agricultural environment; and so on.

Of course, not all firms or products are at the same level of readiness. Nonetheless, most will be following the above-mentioned development directions. Furthermore, some firms, in our view, have made wrong technology choices and will not make it unless they do a deep re-think of their choices.

The total fleet size of deployed robots is very small. Even the leading products are still at advanced levels of development, hoping for some sales in this coming or the following year. Nonetheless, products are maturing. The business models are also varied with some following the RaaS and others the equipment sale model. Interestingly, some firms are discovering the claimed ROI does not stack up in their original target. Instead, they are re-focusing on lower value but technically simpler fruits.

This is still the beginning. The incumbent (human) sets a challenging bar in terms of performance and cost. However, the need for automation is real and growing. Technology variability is also demonstrated. In the future, the cost and performance gap will only narrow and eventually vanish.

There are more sectors in farming in which automation is already playing a role. Automated milking has been in the making for 25 years and its multi-billion market is showing high annual growth rates. Drones are an increasingly common tool. Currently, remote-controlled consumer or prosumer drones are utilised for aerial image acquisition.

Many firms are in parallel offering the data analytics, starting from simple indexes such as NDVI and progressing to more complex analytics. Aerial drone-based sprayers have also been launched. These however remain currently niche.