In the field connectors operate in environments with harmful gases like sulfur dioxide or nitric oxide which in combination with humidity may lead to corrosion. These effects can result in malfunctions or damages during the life cycle of the products. Harmful gas tests are used to verify the related quality and robustness of the products. There are gas tests with single gases or tests according to method 4 using four different gases in the test chamber which is closer to real environments. The harmful gas tests for the PROVERTHA connectors were conducted in accordance to the standard DIN EN 60068-2-60 method 4 (test standard DINEN61076-2-101 BM 3.1).

The visual inspection of the connectors after testing could not detect any cracks, chipping, deformation, abrasion or other mechanical damage. The measurements of

the volume resistance before and after the harmful gas test showed no significant differences.

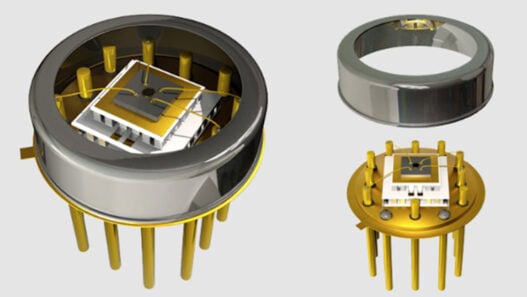

The tested M12 crimp connector with D coding and IP67 is part of the PROVERTHA portfolio for railway applications. The crimp connector fulfills the needs of the railway industry on high robustness and the usage of standard cables. Thanks to its very compact form factor with only 16 mm total diameter for a field assembly solution, the new connector fits applications with restricted mounting conditions. For rack or panel feed-thru a compact field mountable rear panel crimp cable connector in female version is available.