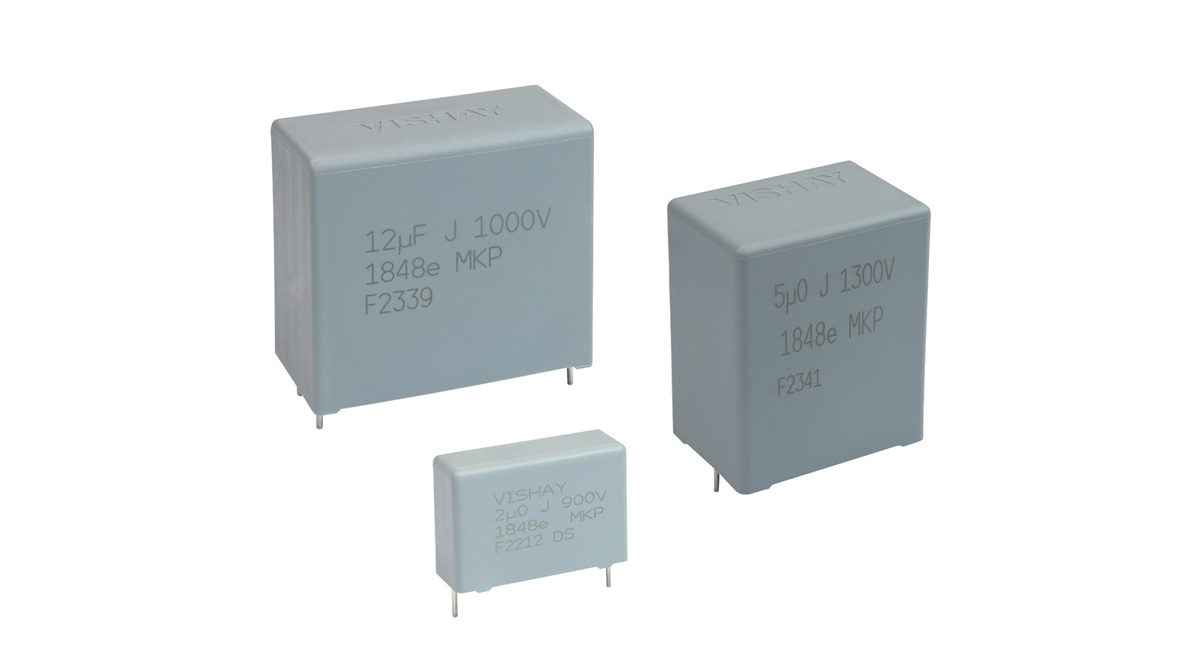

Vishay Intertechnology recently itroduced a new AEC-Q200 qualified DC-Link metallised polypropylene film capacitor engineered for the harsh conditions of automotive, energy, and industrial applications.

Offering high temperature operation up to +125 °C, the Vishay Roederstein MKP1848e provides ripple current up to 44.5 A and withstands temperature humidity bias (THB) in accordance with Grade III of IEC60384-16 ed.3 – 60 °C / 93 % R.H for 1344 hours at rated voltage.

With its high temperature operation and resistance to high humidity, the automotive grade capacitor released today is well suited for automotive power conversion applications such as on-board chargers (OBC), power trains, HVAC systems, e-compressors, and DC/DC converters.

Furthermore, this next-generation DC-Link capacitor addresses the stringent needs for energy and industrial power conversion applications such as fast chargers, solar inverters, rectifiers for hydrogen electrolysers, battery storage systems, motor drives, and UPS.

The MKP1848e offers rated capacitance from 1 µF to 140 µF and low ESR down to 1.0 mΩ, in rated voltages from 500 VDC to 1300 VDC. The devices provide 25 % higher ripple current density than previous-generation solutions with the same volume, while its compact footprint and pitch options down to 22.5 mm enable volume reductions up to 40 % and 15 %, respectively, at 500 VDC and 900 VDC.

To meet the standard high voltage levels of electric (EV) and plug-in hybrid electric vehicles (PHEV), the MKP1848e withstands operating voltages from 250 VDC to 800 VDC at +125 °C for a limited time. It also features high thermal shock capabilities — withstanding 1000 temperature cycles from -40 °C to +125 °C, with a 30-minute dwell time for each temperature extreme. The capacitor is available with customsed terminals upon request.