The Delta S3 simulator satisfies a growing demand for high-fidelity, high-dynamic, human-centric vehicle simulations in both road and motorsport applications.

Designed and manufactured in-house in Hethel, Norfolk, Ansible Motion’s all-new AML SMS2 Stratiform Motion System is at the heart of the Delta S3’s dynamic capabilities, delivering a refined physical experience. The Delta S3’s scalable architecture also means that it can be built and delivered in multiple size options, making it suitable for a broad range of automotive product development use cases such as expert driver assessments, chassis dynamics, powertrain driveability, ADAS and active safety function calibration, V2X studies and HMI design evaluations

Sustained motions ideal for evasive actions or autonomous parking

Drawing on feedback from its growing customer base of some of the leading global OEMs and Tier One suppliers and more than a decade of simulator development in the field, Ansible Motion’s all-new Delta series S3 delivers accelerations beyond 1G, velocities above 5m/s and class-leading frequency response. The simulator is capable of full 360° dynamic yaw rotations, and a set of engineered linear rails – scalable from 4 to 10 metres in length – enables sustained, independent sway and surge motions for a more immersive and representative experiences for manoeuvre such as aggressive lane changing and autonomous parking, and anything in between.

Flexible for both road and track applications

Another key innovation from Ansible Motion is its patent pending mechanism that carries the cabin. This system offers a further three degrees of freedom (heave, pitch and roll) to the vehicle motion profile. Crucially, this novel design means a vehicle cabin up to 500kg can be exercised dynamically in all six degrees of freedom (the maximum possible for defining the motion of a body), at any point. This solution avoids the usual, complex interactions between multiple motion controllers in the control system, which can lead to inconsistencies in the motion depending on the current position or velocity of the vehicle, and it eliminates the drastic reductions in usable motion space that can occur with parallel motion systems.

It also dramatically reduces the complexity of controlling and tuning the motion system for different use cases. This has practical implications for Ansible Motion’s customers: The Delta S3’s proprietary motion control system means human evaluators can experience the full range of vehicle behaviours from low-dynamic to high-dynamic with smooth, nuanced motion and extremely low latency. This is mission critical when real people wish to participate in virtual test drives so they can safely and efficiently evaluate tomorrow’s vehicles today.

“Our new Delta series S3 addresses a requirement from both OEMs and Tier Ones for a highly capable and versatile driving simulator – a single virtual environment that delivers everything needed to convincingly engage real people with the automotive product development process, early and often, sometimes well before prototype vehicles exist,” said Ansible Motion’s director, Kia Cammaerts. “We have always focussed on achieving high-dynamic and high-fidelity motion for all six degrees of freedom that define a vehicle’s movement. The new Delta series S3 simulator expands on this in all areas, ensuring it’s a dependable tool that meets the demands necessary to validate future automotive technologies.”

With simulation now a key enabler for vehicle manufacturers to develop their ever-increasing range of new vehicle technologies and advancements, Ansible Motion is ensuring that the Delta series S3, as a single tool, is a capable, effective and an appropriately leading-edge means of supporting the varied requirements of OEMs around the globe.

Test collision avoidance systems safely

Vehicle dynamics and chassis development engineers are set to welcome the Delta series S3’s ability to achieve high dynamic responses in heave, pitch and roll, while the linear rails provide the opportunity to do 1:1 motion cueing for lane change manoeuvres, and the rapid changes of direction for developing onboard safety technologies such as stability control and collision avoidance systems.

Validate interactions with pedestrians

For validating urban driving systems, the Delta series S3’s 360° yaw capability, complemented by the new 360° panoramic vision system, will be particularly beneficial in eliminating the human immersion inconsistencies that have been a barrier for many drivers in trusting driving simulators to assist in the pre-protype development of certain systems such as blind spot and pedestrian detection systems.

Connect and drive a powertrain located anywhere in the world

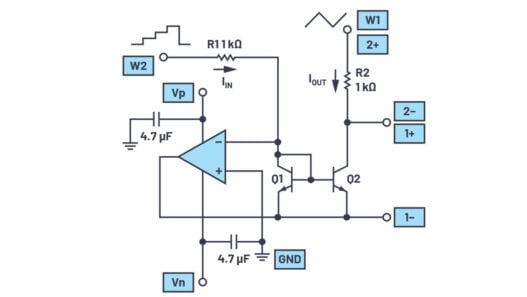

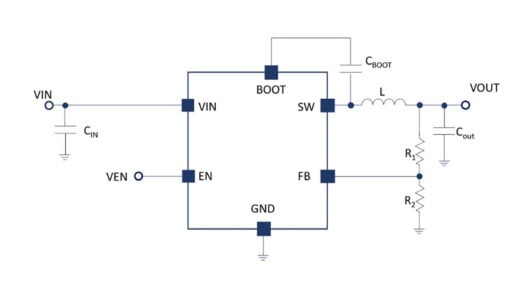

Powertrain engineers will relish the Delta series S3’s ability to replicate the greater accelerations and nuanced dynamics required to develop and tune their systems. In addition, the Delta S3 utilises the latest version of Ansible Motion’s AML DDB Distributed Data Bus, a powerful, synchronous real-time computing environment with open and modular software architecture that enables connectivity to the external simulation environments and Hardware-in-the-Loop (HIL) test benches required for drivetrain developments. Effectively, this means the Delta S3 provides an opportunity for engineers and evaluators to actually drive a car with a brand-new combustion engine (ICE) or electric powertrain unit that may be operating on a dyno in a completely different location.

Open architecture

Mindful of the flexibility that has historically endeared Ansible Motion driving simulators to development engineers, the Delta series S3 still provides an open software and hardware architecture which allows the use of almost any solution for real time vehicle modelling, scenario simulation, graphical rendering or supplemental cueing, whether they be provided by Ansible Motion or a third party.

The announcement of the Delta S3 simulator follows a period of sustained growth for the Norfolk-based specialist. To cater for the increased demand for driving simulators, fuelled by the increasing complexity of vehicles as well as the restrictions on travel during the pandemic, Ansible Motion has grown its in-house software, mechanical and electrical design, and manufacturing teams, and expanded its facility to produce its newest simulators in quantity. Ansible Motion recently received The Queen’s Award for Enterprise for demonstrating impressive growth in overseas profits and significant year-on-year sales growth over the past three years of operations.