Automotive manufacturer Rimac and Analog Devices (ADI) have collaborated on the former’s C_Two model hypercar, one of the fastest and most technologically advanced hypercars ever built. Patrick Morgan, Vice President, Automotive, ADI and Matija Gracin, Director of Components R&D, Rimac Automobili, discuss the tie-up between the two companies and the EV market as a whole.

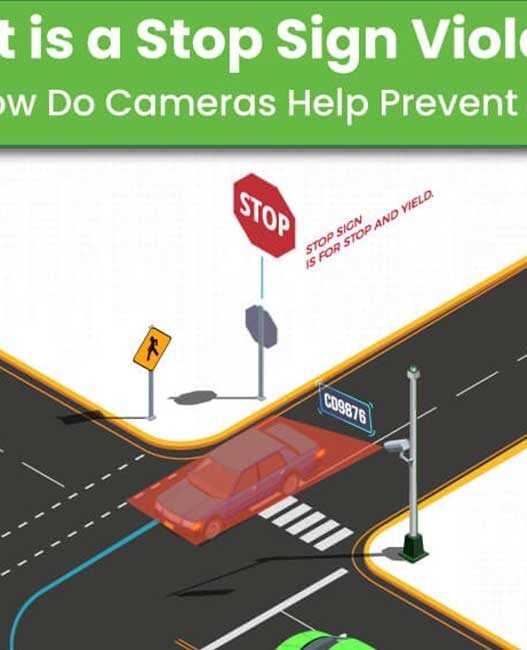

Designed, engineered and produced in-house, the C_Two is made entirely from scratch and features a full carbon fibre monocoque with bonded carbon roof, integrated battery pack and powertrain. The battery pack technology and layout delivers 120kWh energy and 1.4MW of power with exceptional thermal management.

With a top speed of 258mph and a zero to 60mph time of sub two seconds, the C_Two makes devastating use of the instant-torque available to an electric vehicle and the traction made possible by the unique drivetrain and bespoke tyres. More than that, the C_Two maintains its eye-widening acceleration throughout a full-throttle cycle, achieving 186mph from rest in just 11.6 seconds. Next-generation R-AWTV (Rimac All-Wheel Torque Vectoring) controls four electric motors, one per wheel and is available (and necessary) to harness 1,914hp (1,408kW) of power and 2,300Nm of torque – two and a half times the torque output of a contemporary hypercar.

Above: the Rimac C_Two features a full carbon fibre monocoque with bonded carbon roof, integrated battery pack and powertrain

The C_Two is an example of the innovation being seen within the EV market. This innovation is being driven by technology, and the pace of change of this technology innovation has challenged the traditional linear relationship between the car OEMs and the technology suppliers, and has required the two entities to work much closer than they ever have before.

Key to the performance capabilities of the C_Two is the design of the battery and the propulsion system. The Rimac engineers working with ADI had to redesign the whole system from the ground up. The key here is to have a battery management system that can accurately monitor the state of charge and transfer the energy from that battery to the propulsion system in a very efficient way.

Gracin picks up the story: “ADI offers us great support – providing us with all the new components and engineering sample scenarios way before they actually come to the market. Rimac is a technology powerhouse and we are completely driven by innovation and performance. We are simply looking for the best on the market – ADI are definitely that and performance is the reason why we are working together.”

Morgan added: “The C_Two produces 10s of megawatts of power, and yet our technology is making accurate measurements down to a millivolt. That’s an unbelievable technical challenge but solving problems like these is exactly the sort of thing that drives ADI. Another way in which Rimac and ADI are linked together is through a shared vision of electrification. We see the future of automotive as electric and we’ve got those high performance systems that underpin what is enabling that future to come to pass.”

Bumps in the road

Of course, despite the great strides being made, the path to EV adoption and roll-out has rarely been smooth and there are still well-documented barriers to entry that need to be overcome. Gracin highlighted that the biggest three remain energy storage, efficiency (not only of the battery packs but of the entire drivetrain), and infrastructure.

And then of course there is the small matter of a global pandemic. The automotive industry felt the impact of COVID-19 more than most, with the plethora of factory shutdowns which greeted the start of 2020. However, the reduction of carbon emissions which were a consequence of the significantly reduced level of traffic on the roads during lockdown, certainly brought the benefits of EVs into sharp focus for the consumer.

“It has given us a glimpse of what a future with zero emissions could look like,” Morgan commented. “And it’s absolutely one of the major driving forces behind EV adoption. What we see is that the demand for EVs is really growing. The number of projects that were coming to us before the pandemic was high, but that number has grown over the last few months, all around the world.”

COVID-19 has also triggered several megatrends within the industry. People are still avoiding public transport wherever possible and so are spending more time in their cars. This means that the in-car experience (as well as the driving experience) has moved front and centre of customer demands.

Morgan added: “Coming to the fore are technologies like 3D immersive sound, microphone arrays, voice recognition etc – the in-cabin experience has become a really important part of the driving experience. As such we are developing a technology that aims to cancel out noise. A key characteristic of an EV is that it’s very quiet in the cabin. Therefore, road noise may be more noticeable, so it’s important to develop a technology that can cancel that out and make a really immersive driving experience.

“Another megatrend is around range. People want more miles per charge, and the technology is rapidly advancing. It’s achieved, not only with the battery itself, but with the electronics that control it. Those electronics have to be very accurate so that every last bit of charge can be put into and taken out of the battery. This reduces energy consumption overall, so it’s good for the consumer, good for the grid, and it’s a high focus area for us at ADI.”

Sustainability

Gracin added that sustainability is something that is inextricably linked to EVs. Regulations demand that sustainability is implemented both into the design and throughout the complete lifecycle of the EV. Consequently, there are many EU co-funded projects that are focusing on activities in the recycling area for example, where at least 50% of the battery packs need to be recycled.

“However, we are definitely not doing enough,” added Gracin. “Up to 90% of the battery could be recycled, meaning you could reuse it several hundred times. There is also an issue regarding the mining of battery materials so this will have to be implemented into future designs.”

He also raised the issue of battery second life. Once they have served their purpose within the car, they can still be deployed in other applications such as fast charging stations – and some of the larger OEMs like Renault and Nissan are undertaking work in this area.

It is around sustainability that ADI’s wireless BMS technology comes into its own – not only because it eliminates the wire harness altogether, and all the manufacturing complexity associated with it, but it enables the battery pack to be designed in a modular, scalable way. This means that when the battery enters second life, those packs can be matched for a specific application and reconfigured in a way that makes sense.

Morgan added: “The wireless BMS gives you not only the benefit of the wire weight and the flexibility, but also a different way to architect the battery pack. Wireless offers an advantage in the sense that you can have data follow the cell. Making accurate state of charge, state of health calculations at the battery cell and battery module level, wirelessly, gives you a lot of benefits in terms of being able to accurately predict the value of those battery packs for their second life application.

“There’s several ways that we think about sustainability as a technology innovator and provider, and we think about it from the point of view of an end-to-end system, supporting a circular economy. You have power coming into the grid, where it’s about supporting renewable energy. You have efficiency in the vehicle, where it’s all about getting every last bit of charge into and out of the battery (thanks to the electronics that we create). And then it’s about getting energy out of the grid – energy storage systems and vehicle-to-grid technologies that help balance the peak load – these are all important parts of the sustainability equation.”

Batteries included

The beating heart of any EV is of course the battery – both in terms of cost, weight and the packaging space within the vehicle. Therefore, any discussion around the future of EV technology has to incorporate the batteries and their various management systems.

Around 80% of Rimac’s efforts is dedicated to batteries, Gracin explained. However, he added that the chemistry, technology and design currently being used within EVs today has almost reached its limits, and as such a change in philosophy is required to see improved performance.

“For the last ten years not a lot has changed with regards to batteries,” he added. “The lithium air batteries and solid-state batteries we were discussing a decade ago are still being talked about now. If you take a look at the applications we are involved with, we are squeezing every little bit out of the battery. We are focused on performance, but we are reaching the limit of current designs, so a lot of innovation will have to happen in the future.”

Morgan continued: “From a technology and chemistry perspective, there are multiple chemistries that are being developed now – not only solid-state chemistry, but also there’s a movement back to zero cobalt. Some of these chemistries are new, some of them have been around for a while, but they’re proven, safe, low cost and are appropriate for certain segments of the market.

“And as you start to look at the mass market, what we see is a need to support a whole range of different types of battery chemistry. That has an impact on us as a technology supplier, in terms of enabling the use of multiple types of battery chemistries so that the whole supply chain can operate efficiently.

“We also have the whole issue around battery second life, and we see a whole new set of ecosystem players that we are going to interact and partner with – recyclers, battery makers, and of course the OEMs themselves – all of this is becoming a pretty significant industry. If you multiply the number of EVs by the amount of lithium, it is by far the number one driver of the entire battery industry, so we see it as a very interesting and very dynamic sector.”

In conclusion Morgan highlighted that there is no question that the automotive industry is at an inflection point and that the future is electrified. And on top of that, he added that innovation is about people looking at problems differently. “As we go through the pandemic and adapt, perhaps that is bringing us together around some shared values which will enable us to aim towards an electrified future together – innovation and working together in partnership is really the foundation of that. ADI and Rimac is a great example of how we can continue to build more innovation for the future.

“Finally, from a user perspective, if you haven’t done so already, get behind the wheel of an electric vehicle and go for a drive. You’ll see the difference; you’ll feel the difference. And it’s a great experience. And the technology is getting to a place where we’re going to start to see mass adoption of these vehicles.”