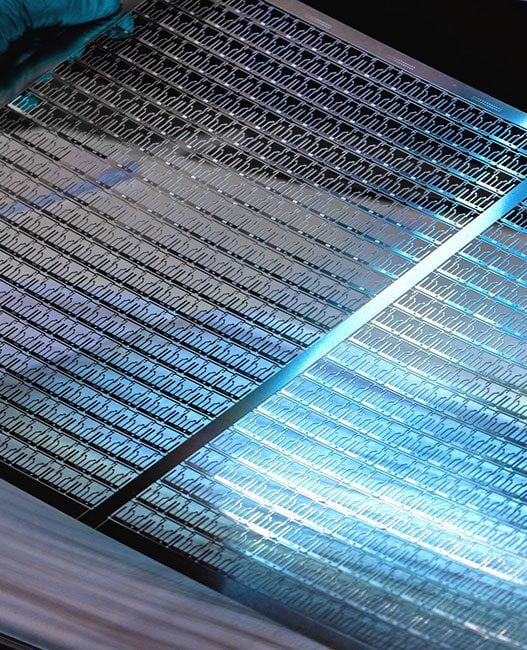

The deployment of AnalogicTech’s ModularBCD process technology is part of the VIS strategy to extend its process spectrum of BCD (Bipolar-CMOS-DMOS) technology, and enhances the position of VIS as a leader in the specialty foundry industry. For AnalogicTech, manufacturing ModularBCD wafers in world-class VIS facilities furthers its corporate strategy to re-use DRAM fabs for the production of new-generation power management ICs – products benefiting from process technology especially developed by AnalogicTech for such advanced equipment sets. According to the agreement, VIS will manufacture wafers for AnalogicTech and also offer the process for foundry to other fabless companies and IDMs for products that do not compete directly with AnalogicTech’s power management offerings.

Unlike conventional BCD technologies that rely on high temperature processes and expensive epitaxial deposition to achieve electrical isolation, ModularBCD employs a modern, low-temperature CMOS-like manufacturing flow capable of high yields without sacrificing device performance or electrical isolation. Furthermore, the principle of ‘modularity’ means process modules and devices for different voltages can be added or removed in a modular fashion without redesigning circuitry, making analogue and mixed signal circuit reuse a viable design methodology.