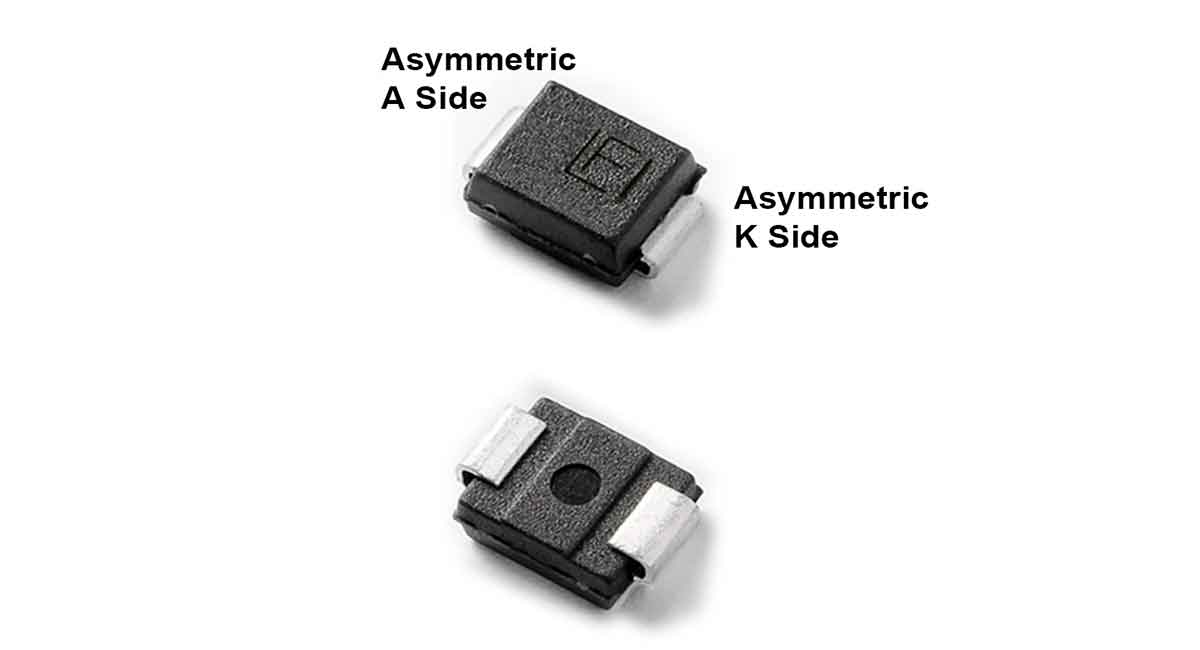

The physical dimensions for the DLCC ceramic packages are designed to fully utilise the recommended solder footprint for the popular MELF packages, and are therefore a drop in replacement for existing board design. Thermal vias improve the heat transfer to the solder pads reducing the diode junction temperature and increasing operating lifetime; options are also available to allow the lid to be connected to the Anode or Cathode. Connecting the metal lid to a known electrical potential stops deep dielectric discharge in space applications; as described in the Space Weather link on Semelab’s web site. www.semelab.co.uk/mil/DLCC

Comments Ros Kruger, Industry Marketing Director, Europe – Military, Aero and Space for TTI, Inc.: “Semelab has 30 years experience in the manufacture of semiconductor devices for high reliability applications. Designed as a cost-effective solution and manufactured in accordance with MIL-19500 and ESA specifications, the new DLCC packages are perfectly suited to meet the challenges of harsh environments.“