The quality of the inspection depends on the concentration and qualification of the operator and is therefore highly variable.

As miniaturisation progressed and packing density was high this procedure was and is very time-consuming, which means that in the case of high quantities, high costs are also incurred.

With CORS Digitaltest has developed a special procedure which uses a fully automated camera system.

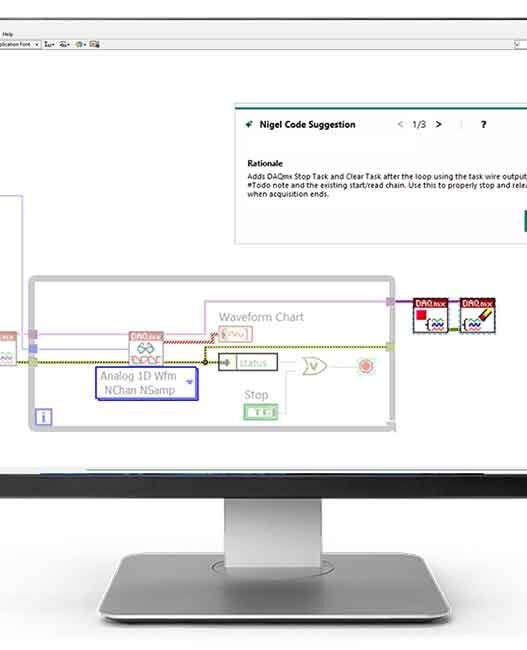

The IP-3000 optical inspection system is centrally controlled via the QMAN Repair Stations software, and shows the fault location as a live image on a high-resolution monitor. It then imports the test results from different test processes, which in turn allows a faster analysis.

In case of an error, the defective assembly can then be repaired by QMAN in the shortest possible time.

The solution is in the detail, in the case of CORS, in the camera system of the IP-3000 inspection system: the side cameras installed there make both solder joint control and faster detection of short-circuits possible.