The rotational flow demonstration kit will be demonstrated at the Renesas booth (hall 1, booth 350) during embedded world 2017, which will take place 14th-16th March in Nuremberg, Germany.

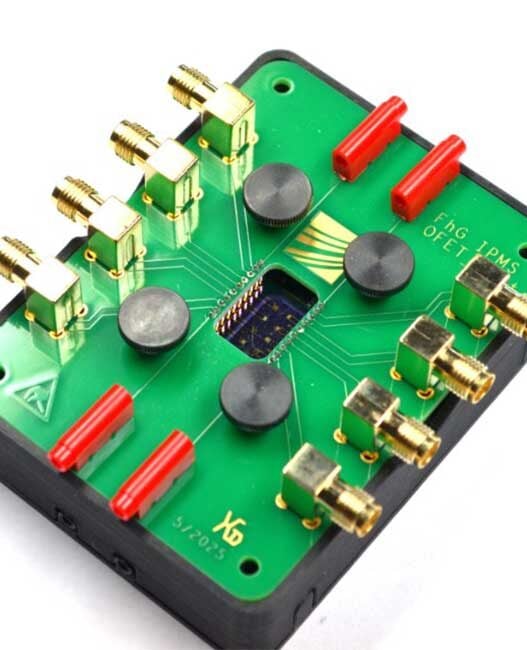

The rotational flow demonstration kit detects the rotational position using the MCU’s on board Data Transfer Controller (DTC) function, a form of state machine, while the MCU’s core is in stop-mode state. This ensures that the average power consumption is kept as low as possible, with IAV (average current) at 4.5μA and a 32 sample burst per second.

The flow demonstration kit senses the flow direction and volumetric flow rate of water and gas, and can also detect reverse flow. The demonstration kit is applied using an active inductive method. Two coils are used to sense the rotational position of a part-metalised disk, and a third coil is used to generate a reference signal.

Renesas’ rotational flow demonstration kit uses a simple electric motor to drive a metalised wheel to simulate the flow. System designers can control the sensor disk’s Revolutions Per Minute (RPM) by tuning the motor’s Direct Current (DC) voltage. An optical sensor is included to determine the exact RPM of the disk. System designers can visualise the data captured by the new demonstration kit with Renesas’ e² studio software development environment, which includes an easy-to-use debugger Graphical User Interface (GUI).