Aptiv and Vecna Robotics have established a strategic collaboration focused on the joint development of next-generation autonomous mobile robot (AMR) systems to deliver material handling solutions in industrial environments.

Under the terms of the partnership, Aptiv’s advanced perception technologies and machine learning (ML) capabilities will be tightly integrated into Vecna Robotics’ advanced autonomy and orchestration platform, delivering robust AMRs.

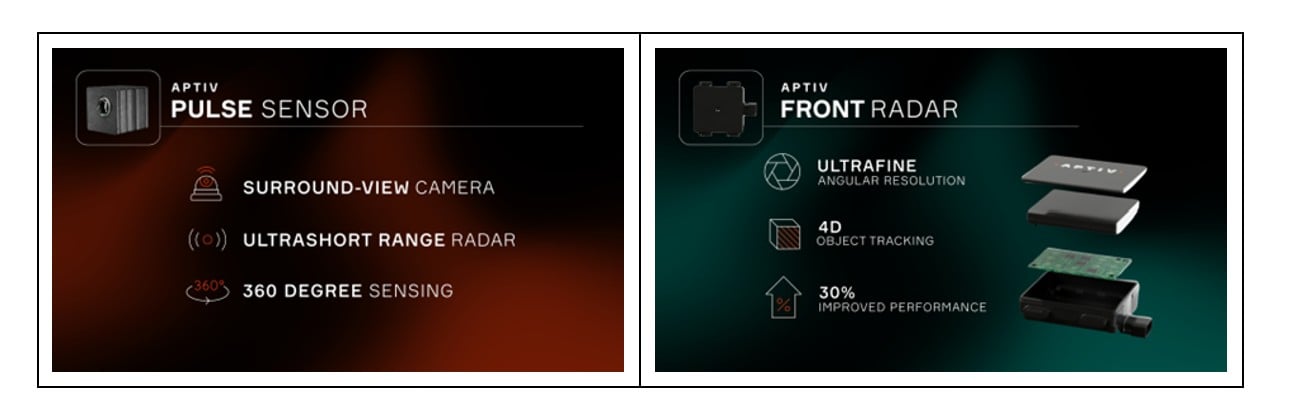

The combined solution incorporates several core capabilities, including Aptiv’s PULSE Sensor for environmental sensing and Aptiv Radar ML and Behaviour ML technologies for real-time perception and adaptive path planning.

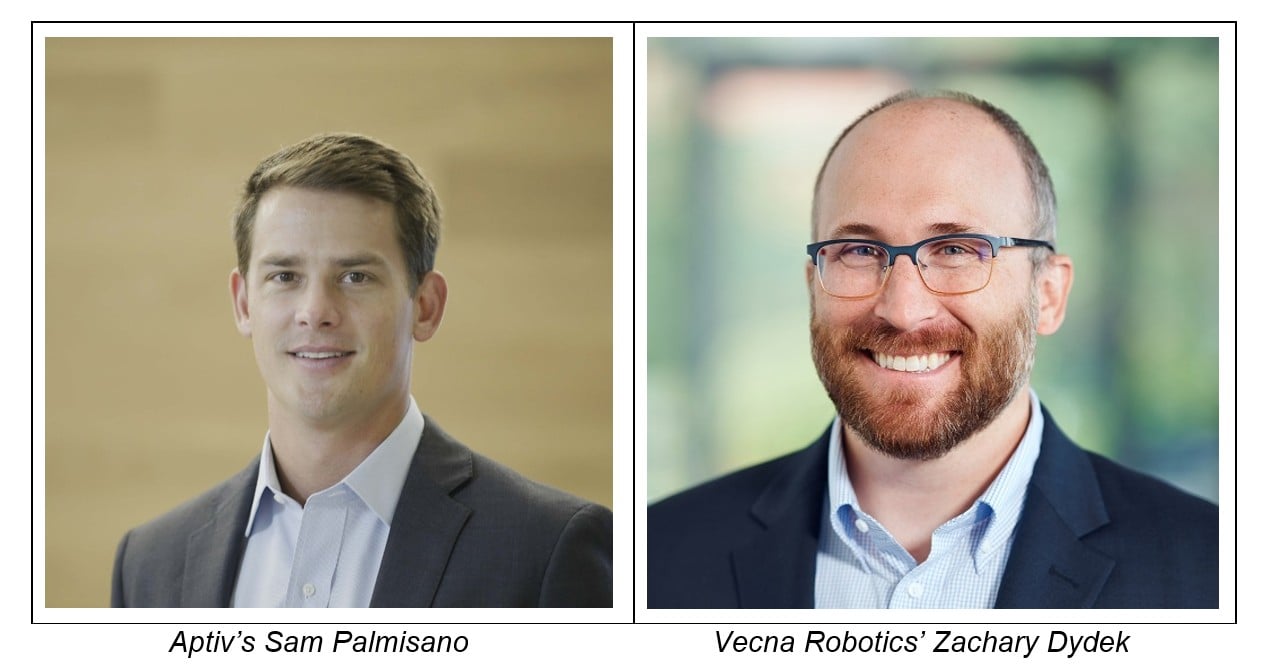

In an exclusive interview for Electronic Specifier, Sam Palmisano, Vice President & Managing Director, Autonomy & AI/ML, Aptiv and Zachary Dydek, Chief Technology Officer, Vecna Robotics, emphasised that integrating advanced perception with fail-safe navigation maximises performance while preserving existing operational processes.

Next-generation AMRs for industrial evolution

Next-generation AMRs represent a convergence of intelligent perception, Edge-ready compute platforms, and Cloud-native software – delivered through proven AMR platforms like Vecna Robotics’.

“This integration allows AMRs to sense, think, and act in real time – delivering measurable improvements in reliability, safety, and operational efficiency within dynamic, mixed-traffic industrial environments,” Palmisano said.

Through its collaboration with Vecna Robotics, Aptiv is translating proven automotive and ADAS technologies to industrial automation.

Palmisano added: “Our PULSE sensor system and Radar/Behaviour ML capabilities – originally developed and validated in demanding automotive applications – can provide high-precision object detection and obstacle avoidance for AMRs operating in fast-changing industrial settings.”

These safety-critical systems ensure that AMRs can navigate confidently alongside humans, forklifts, and other automation systems while maintaining workflow continuity and maximising throughput using existing infrastructure.

“Our scalable compute platform, built on Wind River’s VxWorks RTOS and Helix Virtualisation Platform, delivers performance, ultra-low latency, and design flexibility required for diverse AMR configurations, accelerating deployment at scale while maintaining proven, automotive-grade reliability standards,” Palmisano explained.

By pairing Vecna’s autonomy and fleet orchestration with Aptiv’s perception and embedded software technologies, the collaboration enables safer, more efficient AMRs that scale reliably across large fleets while reducing costs and improving operational robustness.

Safe & efficient material handling

Aptiv’s technology brings several key advantages to next generation AMRs used in material handling:

- Enhanced safety: continuous 360° situational awareness – powered by Aptiv PULSE (integrating shortrange radar with bird’s-eye-view camera) and ML-based perception – enables AMRs to detect and react to obstacles at increased range, relative to today’s existing solutions. This supports safer navigation in crowded, unstructured, or mixed pedestrian and forklift environments

- Operational efficiency: advanced perception systems enable precise task coordination across human workers, forklifts, and automation systems. Improving workflow continuity and maximising throughput within existing facility layouts without requiring infrastructure modifications

- Fleet scalability: Cloud-native, modular software architecture combined with over-the-air update capabilities and proven, automotive-grade hardware enables rapid deployment, simplified maintenance, and continuous performance optimisation across entire fleets throughout their operational lifecycle

Versatility across industrial environments

Aptiv’s technology enables AMR deployment in mixed-traffic industrial environments, including:

- Warehouses and distribution centres requiring high-density operations with human workers

- Manufacturing floor operations with complex, evolving production workflows

- Logistics facilities managing unpredictable material flow patterns

“These environments demand AMRs that can operate in close proximity to humans and mobile equipment, navigate unpredictable obstacles in real time, and adapt to rapidly changing operational requirements,” Palmisano said.

By combining Vecna’s real-world deployment experience in these environments with Aptiv’s automotive-grade perception and compute technologies, the collaboration delivers the reliability, responsiveness, and adaptability required for high performance automation across diverse industrial use cases.

“It’s worth noting that the same sensing, compute, and software technologies are relevant across a broader set of emerging Edge autonomy markets. Aptiv is actively engaging with partners in areas such as industrial drones, nonautomotive autonomous ground vehicles, and other robotics platforms – markets that face similar challenges around perception, scalability, and safety,” Palmisano commented.

These markets also benefit from Aptiv’s long‑standing strengths in wiring, connector systems, and high‑reliability interconnect architectures, which are essential for enabling ruggedised, low‑cost, and interoperable hardware‑software integration.

Integrating Aptiv perception & ML into Vecna Robotics platform

The integration encompasses three core technology components from Aptiv’s portfolio:

- Perception and sensing hardware

PULSE Sensor: an award-winning, compact sensor delivered both at lower cost and with higher performance than the other market alternatives. Aptiv PULSE combines surround-view camera technology with ultra-short-range radar for reliable, accurate 360-degree environmental sensing - ML based real-time intelligence

Aptiv Radar ML and Behaviour ML: advanced machine learning algorithms enabling real-time perception, predictive behaviour modelling, and dynamic path planning in complex, unstructured environments - Embedded software and compute platform

Built on Aptiv’s scalable, high-performance compute architecture featuring Wind River’s VxWorks RTOS and Helix Virtualisation Platform, delivering best-in-class performance, advanced virtualisation, ultra-low latency, and exceptional flexibility to support diverse system configurations

Palmisano added: “Together, these technologies give AMRs a far more detailed and reliable understanding of their surroundings than traditional industrial sensors.”

Core capabilities of the integrated solution

As highlighted in the announcement last December, this collaboration will deliver a new class of industrial AMRs with safety-critical performance standards:

- Real-time situational awareness with 360-degree obstacle detection and avoidance

- Predictive behaviour modelling for human-robot interaction

- Dynamic path planning optimised for mixed-traffic environments

- Scalable fleet management with OTA software updates

- High-reliability operation meeting demanding industrial requirements

- Orchestration of workflows across humans, AMRs, and other automation systems

“While it is early in the development cycle, the fundamental value proposition is clear: applying validated automotive perception, compute, and software technologies to industrial automation can improve AMR safety, efficiency, and scalability. Additional details were provided in the press release,” Palmisano explained.

Real-time safety with advanced obstacle detection

Vecna Robotics’ platform is built on a multi-layered navigation safety architecture designed for safe operation in fast-moving, mixed-traffic industrial environments.

“With 360-degree sensor coverage, three independent safety layers, adaptive safety zones that adjust based on speed and direction, and proprietary Free Space Reasoning, Vecna AMRs continuously detect, anticipate, and safely navigate around people, vehicles, and obstacles in real time,” Dydek underlined.

Through its collaboration with Aptiv, Vecna further strengthens this safety foundation with enhanced perception and object tracking capabilities, improving reliability in challenging and dynamic conditions.

Key advantages of CaseFlow integration

CaseFlow serves as the real-time execution and orchestration layer for case picking operations, transforming autonomous mobile robots from isolated assets into a coordinated, end-to-end system.

“CaseFlow connects human pickers and Vecna’s autonomous pallet jacks directly with WMS, MES, and other enterprise systems to manage, prioritise, and execute work as conditions change on the floor,” Dydek said.

By continuously monitoring locations, priority changes, congestion and material flow, CaseFlow dynamically assigns and reassigns tasks, manages exceptions, and synchronises robots, people, and other workflows in real time.

Dydek added: “This closed-loop orchestration enables higher throughput, faster recovery from disruptions, and predictable performance at scale – delivering measurable improvements in efficiency and reliability.”

Outstanding features of Aptiv embedded software

Aptiv’s integrated software provides several solutions that enhance the performance of next-generation AMRs:

- VxWorks RTOS (Wind River): a deterministic, safety critical real time operating system used in mission-critical domains offering reliability, low latency, and certifiability for mission-critical control loops and real time perception decisions

- Wind River Helix Virtualisation Platform (Helix Hypervisor): a mixed-criticality virtualisation environment that allows diverse workloads (e.g., safety critical perception, autonomy, and non-safety services) to coexist while maintaining isolation, security, and performance – accelerating integration and lifecycle updates in a Cloud native paradigm

- Cloud-native, modular architecture: containerisation, standards-based APIs, and OTA support for continuous improvement and faster time to value across fleets

Looking ahead

Aptiv brings automotive-grade perception, compute, and Cloud-native software – proven across millions of vehicles worldwide – to mission-critical industries such as robotics.

“By combining these strengths with advanced autonomy and orchestration technologies at the intelligent Edge, Aptiv is enabling machines to sense, think, act, and continuously optimise in real world applications,” Palmisano explained.

Through its collaboration with Vecna Robotics, these capabilities are being applied to proven AMR platforms that already operate in demanding industrial environments.

“At CES 2026 we featured the Vecna Robotics’ CPJ CoBot Pallet Jack integrated with Aptiv technology – including PULSE 360° perception and ML based navigation for confident manoeuvring in mixed traffic and unstructured spaces,” Palmisano concluded.

Together, Aptiv and Vecna are advancing a new generation of autonomous material handling solutions that improve safety, scalability, and operational efficiency without requiring changes to existing infrastructure.

About the author:

Diego de Azcuénaga, Contributing Writer