DesignCon, the United States’ premier annual gathering for chip, board, and systems design engineers, returns to the Santa Clara Convention Center from 24-26th February 2026. For over three decades, this flagship Silicon Valley event has served as the essential forum for industry professionals to discover innovative solutions to the most pressing signal and power integrity challenges.

As a specialist in semiconductor test sockets, Smiths Interconnect announces its participation in this conference and exhibition. It will feature a comprehensive portfolio of its star test products, highlighting solutions engineered for the next generation of technology in AI PCs, Enterprise Data Centres (EDC), automotive electronics, and the Internet of Things (IoT).

Spotlight on innovation: DaVinci Gen V high-speed test socket

Headlining the display will be the DaVinci Gen V high-speed test socket, Smiths Interconnect’s latest product. Designed to meet the extreme demands of high-performance computing and AI data centres, the DaVinci Gen V test socket delivers high-speed signal transmission and performance. It enables digital signalling speeds of up to 224Gbps PAM4 for AI accelerators and beyond 100GHz for 6G communications. These speeds are crucial for supporting the growing demand for massive data transfer.

Product features:

- Solution for BGA, LGA and other variants

- Spring probe technology using homogeneous alloy with gold plating for better grounding

- RF bandwidth > 84GHz @ -1dB IL

- Short signal path 4.90mm test height

- Impedance tuned to match system

- Consistent stable contact resistance 55mΩ (Avg.)

- Hi-coplanarity accommodation

- Tri-temp socket design to support -55 to +150°C

- Designed for manual test, bench test, and HVM production test using the same socket

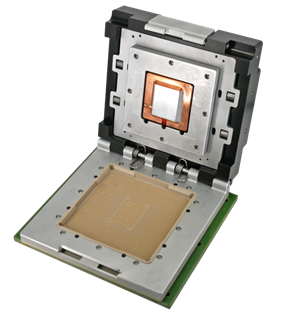

High-power burn-in test socket

Smiths Interconnect’s high-power burn-in socket is a specialised electromechanical interface designed to temporarily connect a semiconductor device (like a CPU, GPU, AI accelerator, or high-power discrete component) to a test board for the burn-in and stress testing phase of manufacturing.

Its primary function is to provide a robust, reliable, and often automated connection that can withstand extreme conditions far beyond normal operation, specifically:

- To support next-generation devices (up to 22,000 contacts, 150 x 150mm)

- Capable of managing up to 2000W of power with integrated liquid cooling

- Universally compatible with all advanced burn-in chamber platforms

- Designed to deliver a 500lb applied load with a maximum closing force of 15lb

- Flexible thermal options including passive heatsinks and heat pipes

This burn-in socket is built for durability and thermal/electrical stability under extreme stress conditions.

Attendees are invited to visit Booth 508 to experience Smiths Interconnect’s technologies first hand and engage with technical experts.