Consumer electronics are part of every person’s day-to-day life, from smartphones and wearables to appliances and home networking devices. Each gadget brings convenience and efficiency, yet behind each unit lies energy storage, power conversion, and signal routing that may hurt users or destroy property when things go wrong.

Electrical safety is a standard that often gets less attention than form factor and fancy add-ons. This should not be the case, as the importance of safety cannot be ignored.

Foundational safety in manufacturing and design

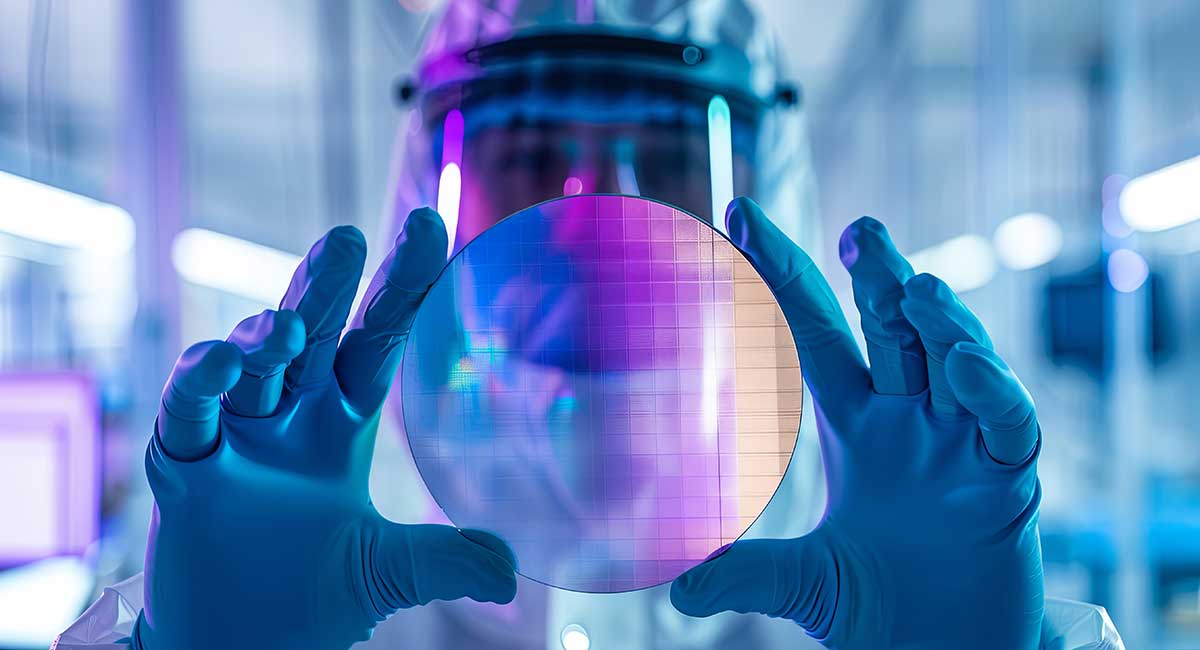

Serious electrical safety practices should begin long before a product reaches certification checks or store shelves. During printed circuit board (PCB) assembly and system integration, factory workers already interact with energised test fixtures and high-density battery packs. In modern EMS floors, safety is treated as a system issue that links grounding, electrostatic discharge control, insulation, and safe work practices across the line.

The United States lists around 1,000 deaths per year due to electrical injuries, with approximately 400 of those linked to high-voltage incidents. Related research on AC shocks shows that currents in the 10mA range can trigger the painful ‘can’t let go’ response, while currents above 100mA through the chest can cause extreme pain and cardiac interference.

In short, any failure that could stop a production operator’s heart at the assembly line can later threaten a consumer during normal use or under fault conditions. Sound safety practices in manufacturing usually focus on controlled grounding, robust insulation, engineered fault handling and regulatory compliance.

Workstations and equipment are bonded to a solid, low-resistance ground, so dangerous voltages are likely to appear on metal parts when something fails. Besides shock protection, good grounding keeps electrostatic discharge under control, influencing overall product safety.

Power supplies and PCB layouts are built so that the insulation and spacing between high- and low-voltage circuits survive surges and wear over the item’s lifetime. Standards such as IEC 62368-1:2023 for ICT and audio-video equipment define required distances and safeguard levels in products rated up to 600 volts to limit shock and fire hazards.

Another matter to consider is compliance with OSHA regulations, which govern how production lines are energised and serviced. Engineering companies that implement safety early usually spend less time dealing with failures and more time improving performance. They also reduce the risk that a subtle layout or insulation shift in pre-production later becomes a recall issue.

Implementing consumer-facing electrical safety features

Once a product is in consumers’ hands, safety turns into a lived experience for users who plug and operate devices in uncontrolled environments. Consider the common consumer-facing safety mechanisms.

Ground-fault and residual-current protection

Many bathroom outlets and countertop appliance circuits in the US are now equipped with Class A GFCIs, which automatically trip when the differential current reaches around 5mA. The National Electrical Code expanded GFCI requirements for certain appliances in 2023 to reduce the risk of shock in wet or conductive environments.

Overcurrent and overtemperature protection

Fuses, current-limited regulators and thermal cutoffs limit energy in fault situations. In phone and laptop power adapters, these devices immediately restrict fault current and disconnect power when the transformer or semiconductor temperatures exceed thresholds.

Protective enclosures and insulation

Smartphone and laptop housings are moulded to keep users isolated from dangerous voltages inside the device. The plastics are flame-retardant, and vents are strategically placed to direct hot air away from the user in case of catastrophic failures.

The UL Standards and Engagement continues to refine guidelines and conduct fire tests across various electronic products, especially those that use lithium-ion batteries. In 2025, the US Consumer Product Safety Commission recalled Frigidaire-branded minifridges after at least 26 reports of smoking, overheating and fires that led to over $700,000 in damages and two smoke inhalation injuries.

Designing for user trust

While regulatory guidelines set the bar for acceptable safety in consumer electronics, brand longevity requires the consistent delivery of quality products. When buyers become accustomed to appliances that never shock or overheat, brand credibility solidifies.

Safety mindfulness in the design process shapes the choices consumers make. Examples include specifying higher creepage for polluted or humid markets or choosing enclosures with better flame ratings than the minimum requirement.

Safety-related recalls can destroy a brand far beyond the immediate cost of replacements and fines. The 2023 CPSC recall of 1.56 million dehumidifiers due to fire hazards showed how safety failures can span multiple brands and stay visible for many years. Engineers and manufacturers who invest in proactive electrical risk analysis and comprehensive verification should see this as a strategic investment in reputation rather than simply a compliance cost.

The future of electronics and safety

As devices integrate higher power density and always-connected sensors into their design, electrical safety becomes even more crucial. Evolving standards and UL’s ongoing enhancements reflect a world where everyday objects integrate complex power systems by default.

For designers and manufacturers, safety mindfulness, testing and field monitoring remain defining skills as technology merges further into public spaces and homes.

About the author:

Lou Farrell is the Senior Editor of engineering and manufacturing at Revolutionized Magazine. His years of experience and passion for writing have given him the ability to craft insightful and engaging explorations of important topics within these fields, educating his readers on anything and everything they need to know.