Electronic waste recycling is the process of collecting, disassembling/dismantling, and processing discarded electronic devices to recover valuable materials while minimising the environmental impact. The recycling process begins with collecting e-waste from various sources, such as household appliances, IT & Telecommunication equipment, consumer electronics, mobile computing devices, industrial electronics, medical equipment, and others. These collected parts are then subjected to sorting the electronics and dismantling them into parts that need to undergo a different technical separation process to recover valuable materials. These dismantled parts are then again subjected to further sorting procedures whereby the process of extraction of the materials is determined. For instance, ram sticks that are initially sorted with all the transistors soldered to them are removed, and the plain PCB with gold or silver printed circuit is separated into the process, where the PCB is subjected to a separation process such as the hydrometallurgical process, to separate the gold metals and silica to repurpose both, gold and silica for various uses. According to MarketsandMarkets the electronic waste recycling market is projected to reach USD 66,331.10 million by 2029, growing at a CAGR of 6.5% from 2024 to 2029. The growth of the electronic waste recycling market is attributed to the increasing demand from the electronics and metal industries. The stringent governmental regulations on landfill management are the major drivers for the increase in electronic waste recycling. Even though the market is expected to grow at a significant rate, the lack of uniform policies around electronic waste disposal and recycling and inactive consumer participation are hampering market growth. Companies realise the benefits of a circular economy, and several electronic manufacturers are adopting recycling as a company-wide policy to attract sustainability-focused consumers and investors. Due to the increasing usage of electronics, electronic scrap generation is expected to increase disproportionately to the planned electronic waste recycling capacities.

The rapid growth in the production of consumer electronics significantly drives the electronic waste (e-waste) recycling market. As technology advances and consumer demand for gadgets such as smartphones, laptops, and smart appliances increases, the volume of discarded electronics is projected to rise significantly. The surge in production and consumption of electronic devices-from smartphones to household appliances-has resulted in an escalating volume of e-waste, now recognised as one of the fastest-growing waste streams globally. E-waste encompasses a variety of discarded electronic products, many of which contain valuable materials such as precious metals and rare earth elements. Recycling not only recovers these materials but also mitigates the environmental hazards of improper disposal. For instance, the improper handling of e-waste can lead to the release of toxic substances such as lead and mercury into the environment, posing significant health risks.

Advanced manufacturing technologies are transforming e-waste recycling by improving the efficiency and safety of material recovery. Robotics and automated systems are being employed to disassemble electronic devices more effectively, enabling the better sorting and extraction of valuable components. This technological revolution enhances recovery rates, reduces labour costs, and minimises human exposure to hazardous materials.

Regulatory frameworks such as the Waste Electrical and Electronic Equipment (WEEE) Directive encourage manufacturers to adopt sustainable practices, including designing products for easier recycling

The increasing production of consumer electronics is a key factor driving the expansion of the electronic waste recycling market. The dual pressures of regulatory frameworks and consumer awareness foster an environment conducive to sustainable electronics manufacturing and waste management practices. As technological advancements continue to evolve, they are expected to further enhance the efficiency. I and effectiveness of e-waste recycling efforts.

Extended Producer Responsibility (EPR) has emerged as a critical driver for the electronic waste recycling market by fundamentally reshaping how manufacturers manage their product lifecycle. EPR mandates that electrical and electronics appliances/equipment manufacturers must take responsibility for the collection, recycling, and proper disposal of their products that have reached their end-of- life. This framework is designed to mitigate the environmental impact of e-waste, which is considered one of the fastest-growing waste streams globally.

This EPR is primarily governed by the national e-waste management rules and regulations of countries. This authorisation ensures that producers establish effective systems for channelling e-waste to authorised dismantlers and recyclers, thereby promoting environmentally sound management practices. Manufacturers must set up collection systems or facilities to ensure that the products that reach their end- of-life do not end up in landfills, which can lead to environmental damage.

EPR encourages innovation in product design and manufacturing processes. By holding producers accountable for their products’ end-of- life management, there is a growing incentive to design electronics that are easier to recycle and contain fewer hazardous materials. The economic implications of EPR are also noteworthy. By promoting recycling and recovery of valuable materials from e-waste-such as metals like gold, silver, and copper-EPR can reduce production costs for manufacturers reliant on these resources. This creates a dual benefit: it lowers raw material costs while simultaneously addressing environmental concerns associated with mining and resource extraction.

Extended Producer Responsibility is a vital mechanism driving the growth of the e-waste recycling market. By placing accountability on producers for their products’ end-of-life management, EPR enhances recycling rates and promotes sustainable practices within the electronics industry.

High initial setup costs and economic viability of Return on Investments (ROI) act as hurdles for new companies to enter the market for recycling electronic waste. To establish an e-waste recycling facility, substantial investments are required to build infrastructure and set up machinery and equipment for the processes. The increasing operating costs for skilled labour, energy, maintenance, and regulatory compliance compound the financial burden on recycling companies.

The volume and type of materials processed heavily influence the economic feasibility of e-waste recycling. Economies of scale are the way to achieve profitability for recyclers. The overall throughput efficiency should stand high to offset the higher setup and operational costs. Fluctuations in commodity prices act as a major hindrance that can affect the profitability of recycling companies.

The recycling process is also complex in nature, demanding higher-order machinery and equipment to operate, thus increasing the costs. The presence of hazardous materials and chemicals such as lead and mercury necessitates the incorporation of extra safety procedures and regulatory compliances.

Regions or countries with low economic development or less e-waste generation increase the chances of economic risks. This, combined with the requirement for high initial investments, puts investors in a reluctant position, which can stifle innovation and slow the development of new infrastructure.

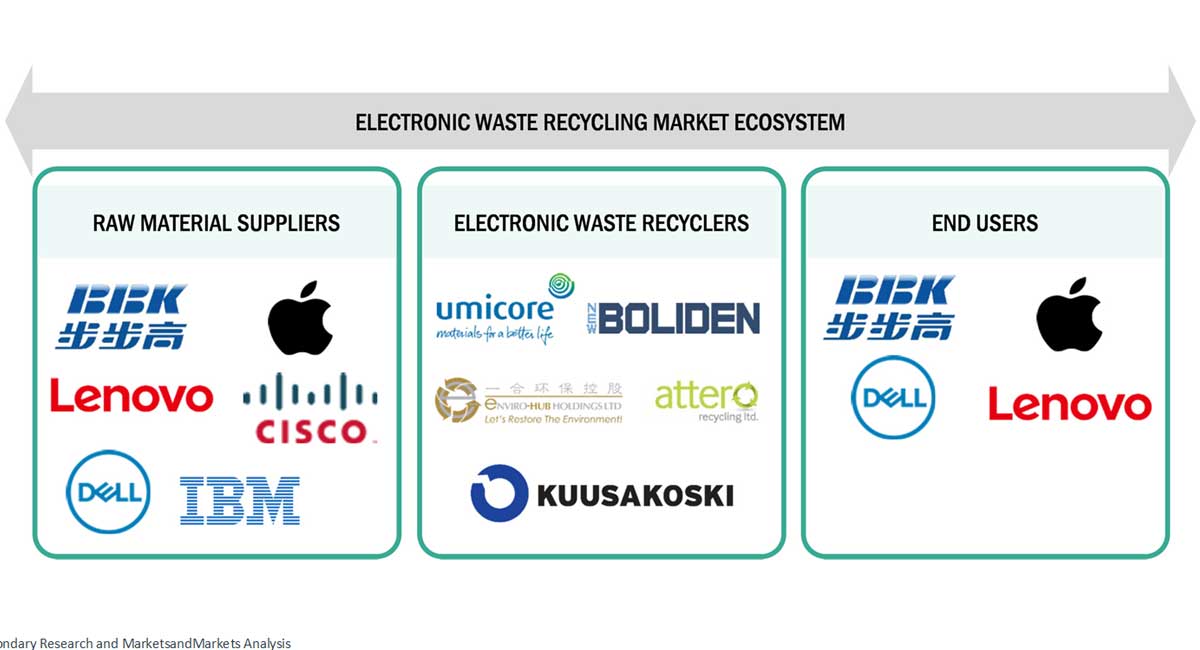

Ecosystem mapping for the electronic waste recycling market involves identifying and analysing interconnected relationships among various stakeholders, including raw material suppliers, recyclers, distributors, contractors, and end users. This mapping delineates the flow of resources, information, and value within the ecosystem, highlighting dependencies, collaborations, and potential disruptions. Raw material suppliers are crucial in providing key materials, while electronic waste recyclers recycle the electronic waste to extract valuable materials and supply them to the end users for their operations. Distributors facilitate the supply chain by delivering products directly to retailers or end users using recycled materials for metal manufacturing, chemical manufacturing, food & beverage industry, and the medical and healthcare industries.