Voyant Photonics has unveiled what it says is the industry’s first fully solid-state 4D frequency-modulated continuous-wave LiDAR system, a move the company believes could accelerate the adoption of advanced sensing across industrial automation, robotics, and consumer devices.

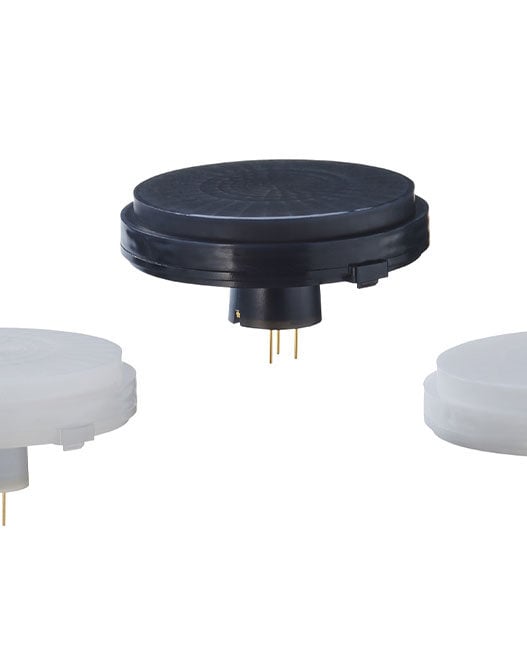

The New York-based group announced its Helium platform, a family of LiDAR sensors and modules built on a silicon photonics chip. The design replaces mechanical scanning components with a two-dimensional photonic focal plane array and on-chip beam steering, resulting in a sensor with no moving parts.

Voyant said the architecture improves reliability and simplifies integration compared with time-of-flight LiDAR systems that rely on MEMS or rotating mirrors. The Helium platform combines depth and per-pixel radial velocity measurement, producing high-resolution 4D point-Cloud data intended for what the company describes as the emerging “Physical AI” market.

The first Helium prototype will be demonstrated at CES 2026 in Las Vegas, from 6th to 9th January, marking Voyant’s transition from research and development into higher-volume manufacturing. The company said the system can support multi-sensor configurations, such as pairing wide field-of-view short-range sensing with narrower long-range detection in a single platform.

Clément Nouvel, Chief Executive Officer, said the new platform was designed to meet demand from industrial and consumer markets for smaller, cheaper, and more reliable sensors. “Helium represents the next step in our mission to deliver the most affordable high-performance LiDAR sensor ever,” he said, adding that the technology could enable new classes of intelligent machines.

Helium builds on Voyant’s earlier Carbon product line, extending its silicon-photonics approach from one-dimensional to full two-dimensional on-chip beam steering. According to the company, the system supports focal plane array resolutions ranging from about 12,000 pixels to more than 100,000 pixels, long-range FMCW performance with velocity sensing, and software-defined scanning that allows adaptive patterns and regions of interest.

The modules can be configured with different lenses to tailor field of view and range, from ultra-wide coverage approaching 180° to narrower, long-range optics. Voyant said the smallest configurations are roughly matchbox-sized, weighing under 150 g and occupying less than 50 cm³, making them suitable for drones, mobile robots, and compact industrial equipment.

By eliminating moving parts and relying on monolithic photonic integration, Voyant estimates Helium offers around a 20× improvement in mean time between failures compared with legacy LiDAR architectures, a metric that is particularly important for high-duty-cycle industrial fleets.

Manufacturing scalability is central to the strategy. Voyant said Helium is produced on the same silicon-photonics platform and foundry ecosystem used in optical data communications, allowing production costs to move towards semiconductor-style economics and avoiding the optical alignment challenges associated with conventional LiDAR systems.

The company is opening an early-access programme for selected original equipment manufacturers and automation partners, offering collaboration on customised chip resolutions, fields of view, module designs, and software-defined scanning features.

Voyant Photonics, headquartered in New York, is positioning its on-chip FMCW LiDAR technology as a foundation for making advanced machine perception as ubiquitous, and affordable, as camera sensors across industrial and consumer applications.