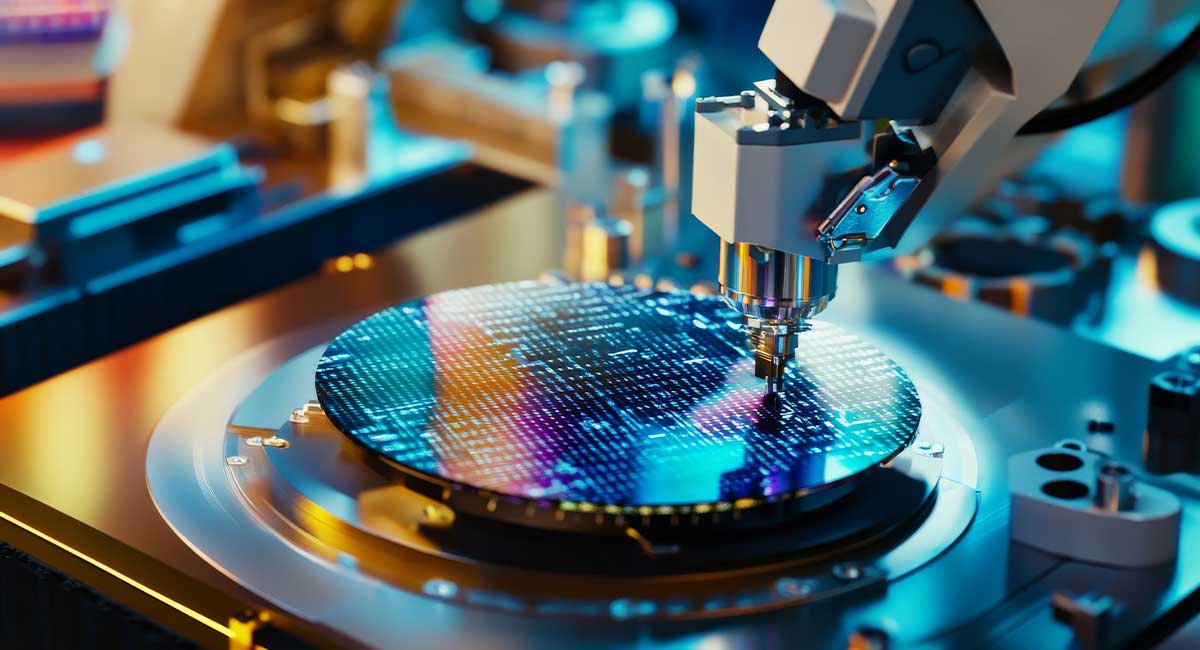

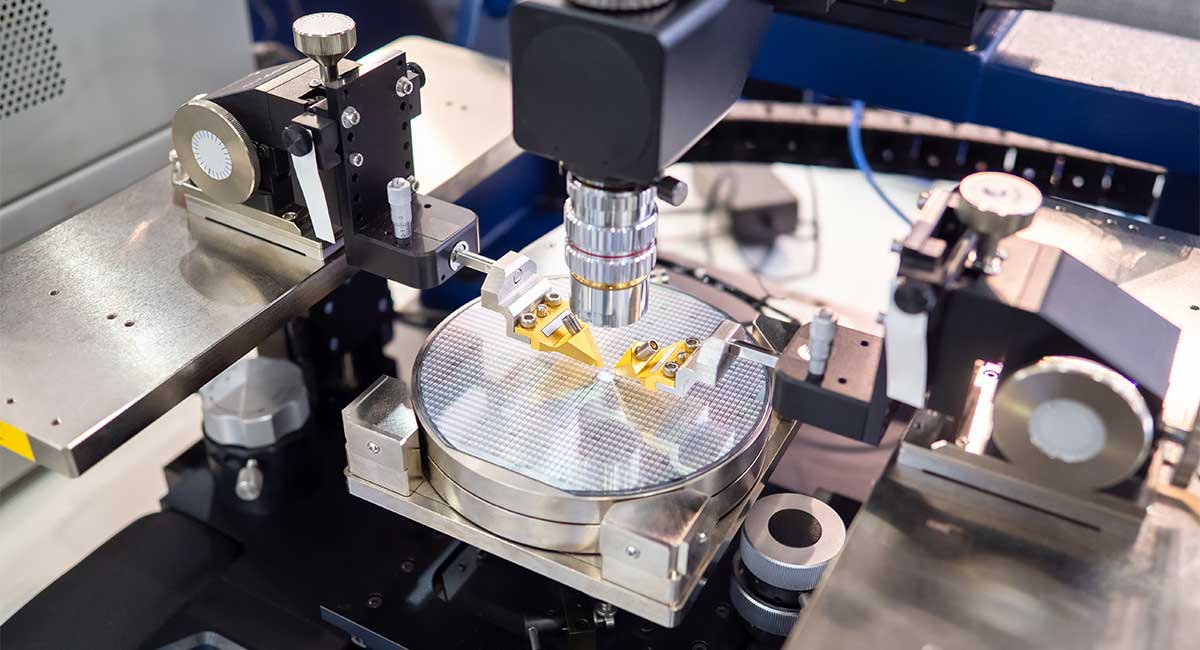

As semiconductor chip technology advances towards nanometre and sub-nanometre scales, the demands placed on metrology tools, such as scanning electron microscopes (SEMs), become exponentially more stringent. These instruments are widely used in semiconductor wafer inspection and defect detection for analysing small features, identifying defects, verifying the integrity of structures, and performing critical dimension (CD) measurements.

While the optics and electron column of an SEM are central to its function, the performance of its high voltage power supply is equally, if not more, critical. The power supply provides the stable, precise voltages required to generate and control the electron beam that scans the sample. Any instability, noise, or drift in this voltage can directly compromise the SEM’s performance, leading to inaccurate measurements, distorted images, and potentially faulty conclusions about the manufacturing process.

The power supply challenge

High resolution SEM applications, particularly in yield-sensitive semiconductor process control and defect inspection, demand extremely stable electron beams. This translates directly to stringent requirements for the high voltage power supply. Key power supply characteristics that significantly impact SEM performance include:

- Low ripple and noise: voltage ripple or spike noise can distort the beam focus or scanning path, leading to blurred or inaccurate images. This distortion over the signal directly affects image quality. Achieving very low ripple and noise is crucial for detector, analytical, and medical applications

- Stability over time: long-term drift in accelerating or focusing voltages can affect dimensional accuracy and repeatability, which is critical for consistent results in semiconductor inspection. Inconsistent image quality or distortion can change over an operational shift if the stability is poor. For instance, a power supply with 70 ppm stability that drifts to 200 ppm over an 8-hour shift can provide vastly different results, potentially leading to false indicators about the manufacturing process or masking issues that were previously detectable. Precision converters are needed to maintain voltage stability over time to minimise drift and enable consistent performance over 8-hour shift patterns

- Stability over temperature: environmental influences, specifically temperature changes, can impact voltage stability. A low temperature coefficient is necessary to ensure stable long-term operation and consistent results, regardless of temperature fluctuations

- Load and line regulation: variations in the input voltage (line regulation) or changes in the load (load regulation) should not significantly alter the output voltage. Precise load and line regulation are vital for maintaining stable voltage output under varying operating conditions

- Low partial discharge: partial discharges are electrical discharges that do not completely bridge the insulation between conductors. In high voltage systems powering SEMs, these discharges can introduce spikes or noise that affect image quality and the overall reliability of the power supply and system. Minimising partial discharges is a critical requirement

In semiconductor inspection, particularly for sub-5nm nodes, even nanometre-scale deviations caused by power supply instability can lead to costly misinterpretation of defect size or location, impacting yield. The demanding size constraints in modern inspection systems also require compact power supply form factors that do not sacrifice performance.

Addressing the challenges

Precision high voltage DC/DC converters, such as those in the HRF series from XP Power, are designed specifically to meet the stringent power supply requirements of critical, noise-sensitive applications. The platform offers several key features that directly address the pain points faced by engineers:

- Low ripple and noise: the HRF15 offers output ripple as low as 0.001%. This ultra-low ripple is critical for maintaining a stable electron beam and producing high resolution, sharp images free from distortion caused by voltage fluctuations

- High stability over time: the series boasts stability as low as 10 ppm/hour and 25 ppm/8 hours after a one-hour warm-up period. This high stability is a significant differentiator compared to alternatives in the market, which may have stability figures like 70 ppm/hour or 200 ppm/8 hours. For a typical 15kV output voltage, a 10ppm stability corresponds to a voltage drift of only 0.15V (15,000V * 10/1,000,000), which is considered a very low drift. This stability ensures consistent beam energy and repeatable measurements over extended operational periods, which is crucial for 8-hour shifts in production environments

- Low temperature coefficient: with a temperature coefficient of 25ppm/°C, the HRF15 minimises voltage variation due to changes in ambient temperature. This ensures consistent performance across the specified operating temperature range of 0 to +50°C

- Excellent load and line regulation: the HRF15 features load and line regulation of 0.001%. This precise regulation ensures that the output voltage remains highly stable despite fluctuations in the input voltage or changes in the applied load

- Compact form factor: the series offers positive and negative 10, 12 and 15kV outputs in a compact package measuring 162.6 x 72.4 x 33mm (6.40 x 2.85 x 1.30”). This small size helps meet demanding size constraints in modern inspection systems without sacrificing performance. Compared to some competitor products, it offers higher stability in a significantly smaller package, less than half the volume in some cases

- Programmability and monitoring: the HRF provides 0 to 100% programmable output voltage and current via an Analogue DC Voltage Programming Input (Vpgm). It also includes output voltage and current monitoring. Advanced features like these are important for supporting modern inspection systems, enabling easy integration into next-generation systems, and aiding in maintaining uptime in high-volume manufacturing environments. Digital communication is also available

Applications within SEMs and beyond

Within an SEM, high voltage power supplies like the HRF15 can be used in multiple locations. One key application is powering the electrostatic lenses. These lenses control the direction of the electron beam, moving it from left to right or right to left, depending on the required scan pattern. The current requirement depends on factors such as the number of lenses powered and the amount of deflection required. While a single beam is common, multi-beam inspection systems, which use hundreds or thousands of beams, also require high-performance power supplies, sometimes with even stricter specifications.

While the focus here is on SEM, the HRF15 series is also well-suited for other applications with similar critical requirements for stability, low noise, and precision. These include mass spectrometry, e-beam/ion beam applications, capillary electrophoresis, high voltage bias, and powering detectors in analytical and medical equipment. Mass spectrometry, in particular, shares very similar requirements to SEM, such as stability over time and low ripple/noise.

Conclusion

The performance of an SEM is fundamentally linked to the quality of its high voltage power supply. Requirements for ultra-low ripple, noise, and drift, combined with high stability over time and temperature, are not merely desirable features but critical necessities for accurate imaging, reliable defect detection, and consistent process control in demanding environments like semiconductor fabs.

The HRF15 series is designed to meet these stringent demands, offering specifications like <0.001% ripple, 10ppm/hr stability, <25ppm/°C temperature coefficient, and <0.001% load/line regulation. These technical characteristics, combined with a compact form factor, 0-100% programmability, and robust protection features, position it as a suitable high-performance solution for powering critical components in SEMs and other noise-sensitive analytical instruments.

About the author:

This article originally appeared in the November’25 magazine issue of Electronic Specifier Design – see ES’s Magazine Archives for more featured publications.