As of 2025, single-phase direct-to-chip (D2C) cooling remains the dominant solution for high-end GPU thermal management. However, as thermal design power (TDP) continues to climb, two-phase D2C cooling is expected to become essential, with large-scale adoption projected around 2026–2027.

IDTechEx has engaged extensively with stakeholders across the data centre value chain, including chip manufacturers, cold plate suppliers, and system integrators. While opinions differ on timing, there is broad consensus that single-phase D2C cooling begins to encounter limitations at approximately 1,500W TDP, reaching its practical ceiling near 2,000W.

Based on historical GPU TDP trends and roadmaps shared by leading chipmakers such as NVIDIA, IDTechEx forecasts that the transition to two-phase D2C cooling is imminent. Detailed analysis and projections are available in the IDTechEx report, ‘Thermal Management For Data Centres 2026-2036: Technologies, Markets, and Opportunities’.

D2C cooling: challenges and trade-offs

Single-phase cooling

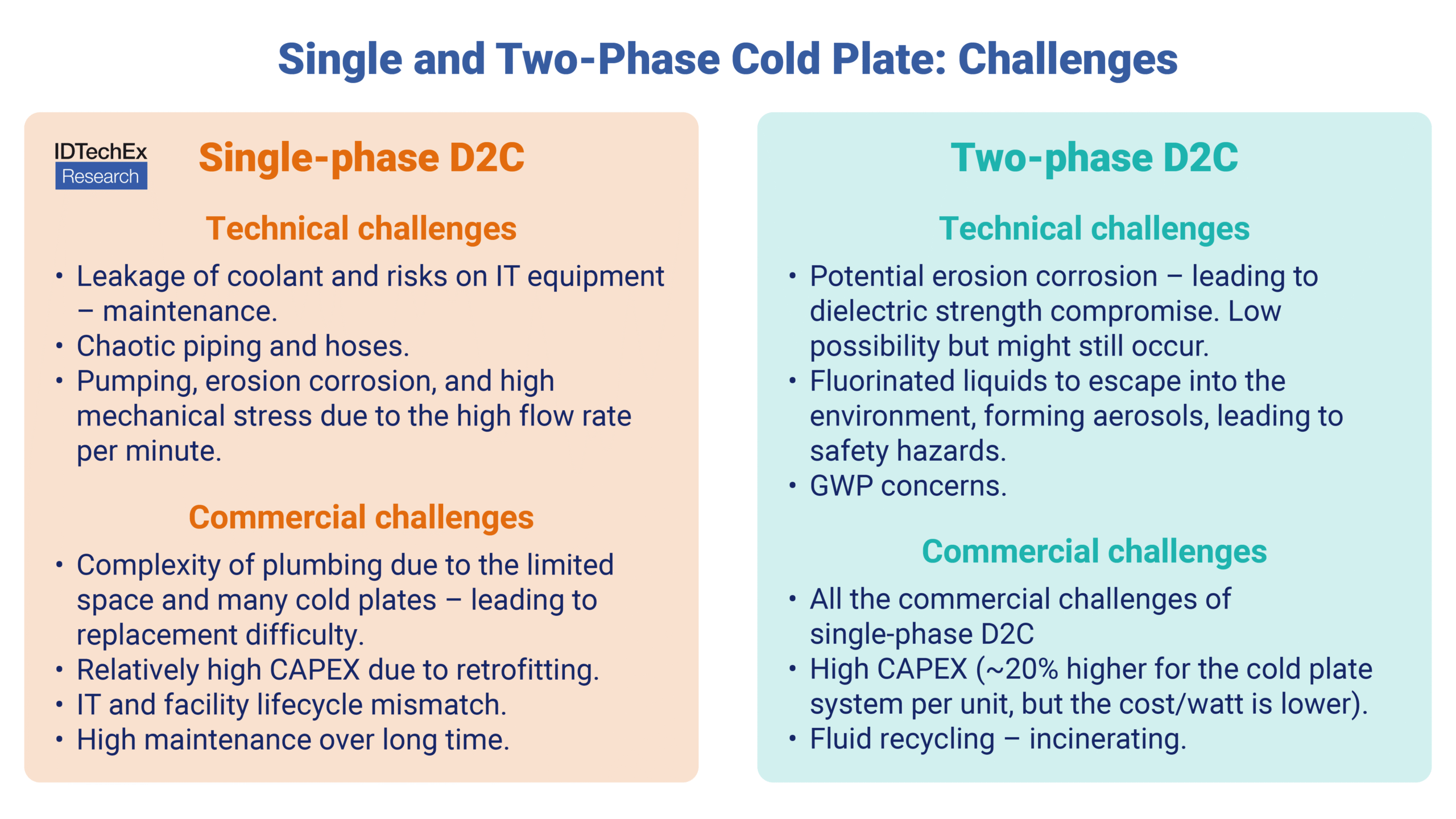

Single-phase direct-to-chip cooling is a well-established and relatively simple technology that uses a liquid coolant, typically a water-glycol mixture (e.g., PG25, etc.), to absorb heat through convection without a phase change. Despite its maturity, it faces key challenges: potential coolant leakage that risks IT equipment damage, mechanical stress from high flow rates, and maintenance complexity due to dense data centre plumbing.

Cooling a 1,000W chip requires roughly 1.5 L/min of coolant, contributing to erosion corrosion and necessitating larger diameter quick disconnects, which increase system costs. Moreover, installation costs are significant, ranging from $200-400 per cold plate system (including QDs, manifolds, hoses, etc.). Although more energy-efficient over time, the high upfront capital expenditure (CAPEX) remains a barrier, particularly for retrofitting legacy data centres.

Two-phase cooling

Two-phase D2C cooling leverages the coolant’s phase change to achieve superior heat dissipation and efficiency at lower flow rates, around 0.3 L/min for a 1,000W chip. This significantly reduces mechanical stress and pumping power requirements. However, the approach introduces environmental and economic concerns.

Fluorinated working fluids, commonly used in two-phase systems, can pose safety risks and contribute to greenhouse gas emissions if released as aerosols. Additionally, the CAPEX for two-phase setups is higher, factoring in not only the cold plates but also the infrastructure for fluid recycling and disposal.

While these systems promise greater thermal performance and potential long-term cost savings, the environmental impact and initial cost hurdles complicate widespread adoption. Nevertheless, careful design optimisation can mitigate some of these challenges. IDTechEx’s ‘Thermal Management For Data Centres 2026-2036: Technologies, Markets, and Opportunities’ quantifies both single- and two-phase cooling CAPEX, providing detailed component-level cost analyses.

Outlook

In summary, single-phase D2C cooling remains simpler and more mature but is constrained by higher maintenance demands and performance limitations. Two-phase D2C cooling offers enhanced efficiency and scalability for next-generation GPUs but faces environmental, technical, and cost-related barriers.

Despite these challenges, IDTechEx expects two-phase cold plates to gain traction, particularly as they offer easier retrofit compatibility compared to immersion cooling solutions. The ‘Thermal Management For Data Centres 2026-2036: Technologies, Markets, and Opportunities’ report further outlines the technical and commercial barriers of both single- and two-phase immersion cooling technologies, along with a detailed roadmap and adoption timeline based on primary and secondary research.