According to 6TL philosophy, 6TL60 design follows the concepts of flexibility, modularity and scalability, in addition to basic key points such as reduced factory footprint, cycle time and standardisation.

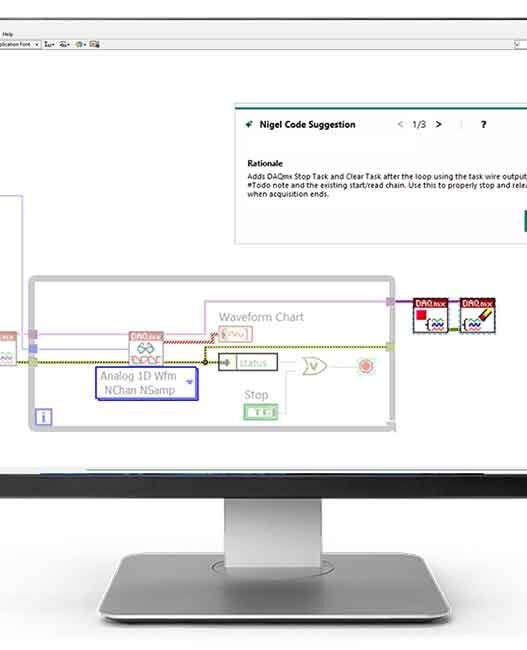

With 5 test positions plus loading/unloading positions, 6TL60 offers a modular and configurable approach which allows FastATE modules to be used to speed-up the test setup integration and reduce the wiring in the system.

From a ROI-centered perspective, 6TL60 rotary test handler delivers an optimal result, combining different test processes in the same platform in a fully automated way.

6TL60 Rotary Test Handler features include:

- Capacity to test DUTs at pcba or end-product level

- 5 test positions + DUT loading/unloading position

- ICT, FCT, boundary scan, HiPot test, flashing, labelling/laser marking, etc

- DUT exchange time <5s

- Max. DUT dimension 350x250mm.

- 19” rack space for instruments integration: 40UH

- 9,5″ rack space for instruments integration: 12UH

- Receiver 8 slots in the fixture + 4 slots in the push plate

- CE compliant