Variable frequency drives (VFDs) offer the best system efficiency in heating and cooling systems, especially if they have an accurate and very wide range of speed control. To obtain truly variable speed control, they use an inverter to control motor speeds, along with high-frequency pulse-width modulation (PWM) switching. Gallium nitride (GaN)-based power switches can additionally help to improve power density, power delivery, and efficiency.

How GaN increases inverter efficiency

The conduction losses attributable to GaN FETs are proportional to the on-state resistance of the GaN, similar to a MOSFET. As for switching losses, GaN FETs offer much lower losses compared to MOSFETs and IGBTs because of these reasons:

- GaN offers zero reverse recovery. With zero reverse recovery, it is possible to switch a GaN FET at a very high current slew rate (di/dt) and voltage slew rate (dv/dt). In MOSFETs, the body diode suffers from high zero reverse recovery, limiting the switching di/dt and dv/dt and causing additional losses and phase-node voltage ringing. With an IGBT, even the addition of an optimised antiparallel diode can still cause challenges related to reverse recovery

- When switching off, IGBTs suffer from minority carrier recombination current, commonly known as tail current, which increases turnoff losses. GaN doesn’t have any tail current

- GaN offers lower capacitance compared to IGBTs and MOSFETs, resulting in lower capacitive switching losses

- Controlled and faster di/dt and controlled dv/dt help optimise voltage-current overlap losses during switching

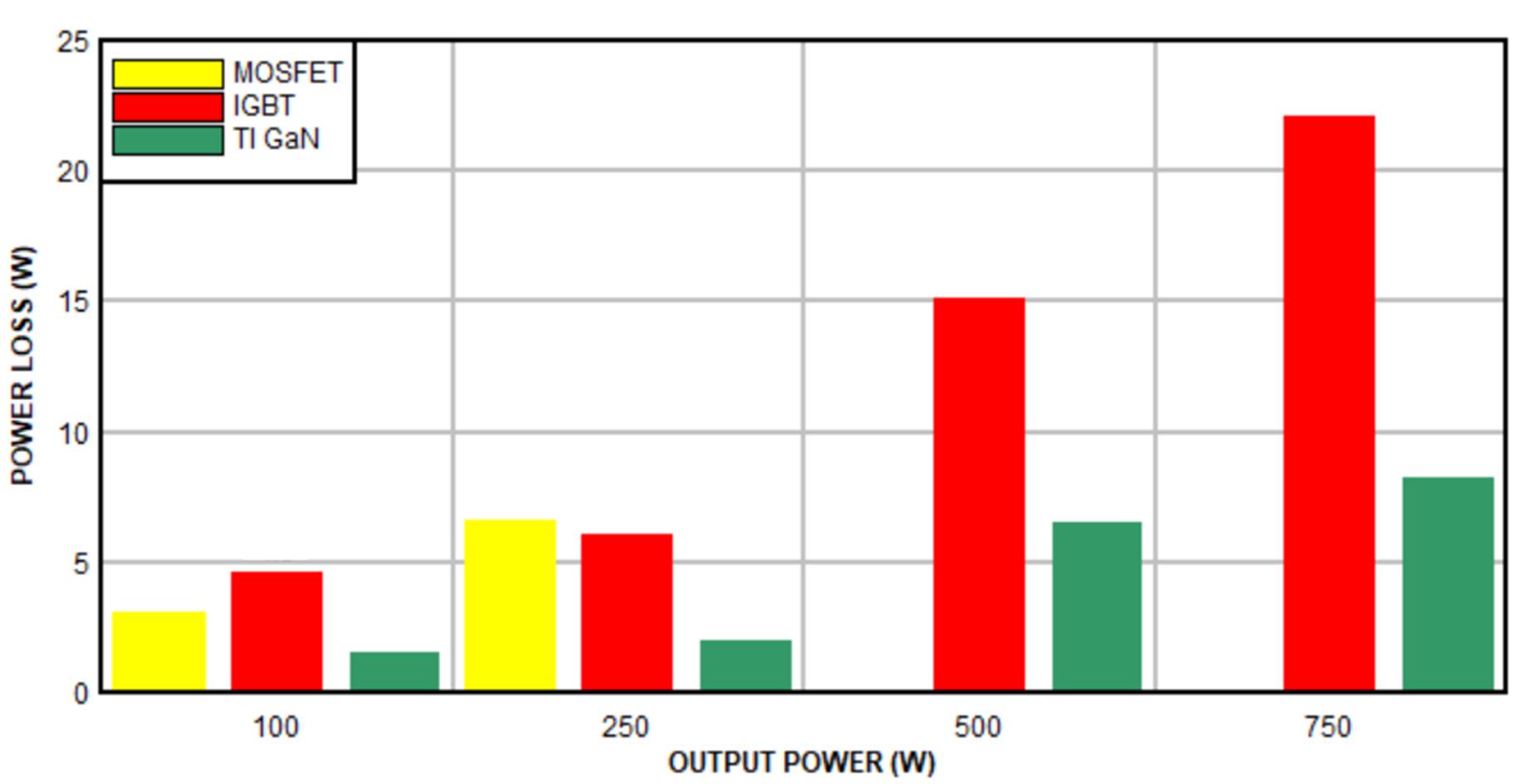

Figure 1: Efficiency comparison of GaN, MOFSET, and IGBT solutions

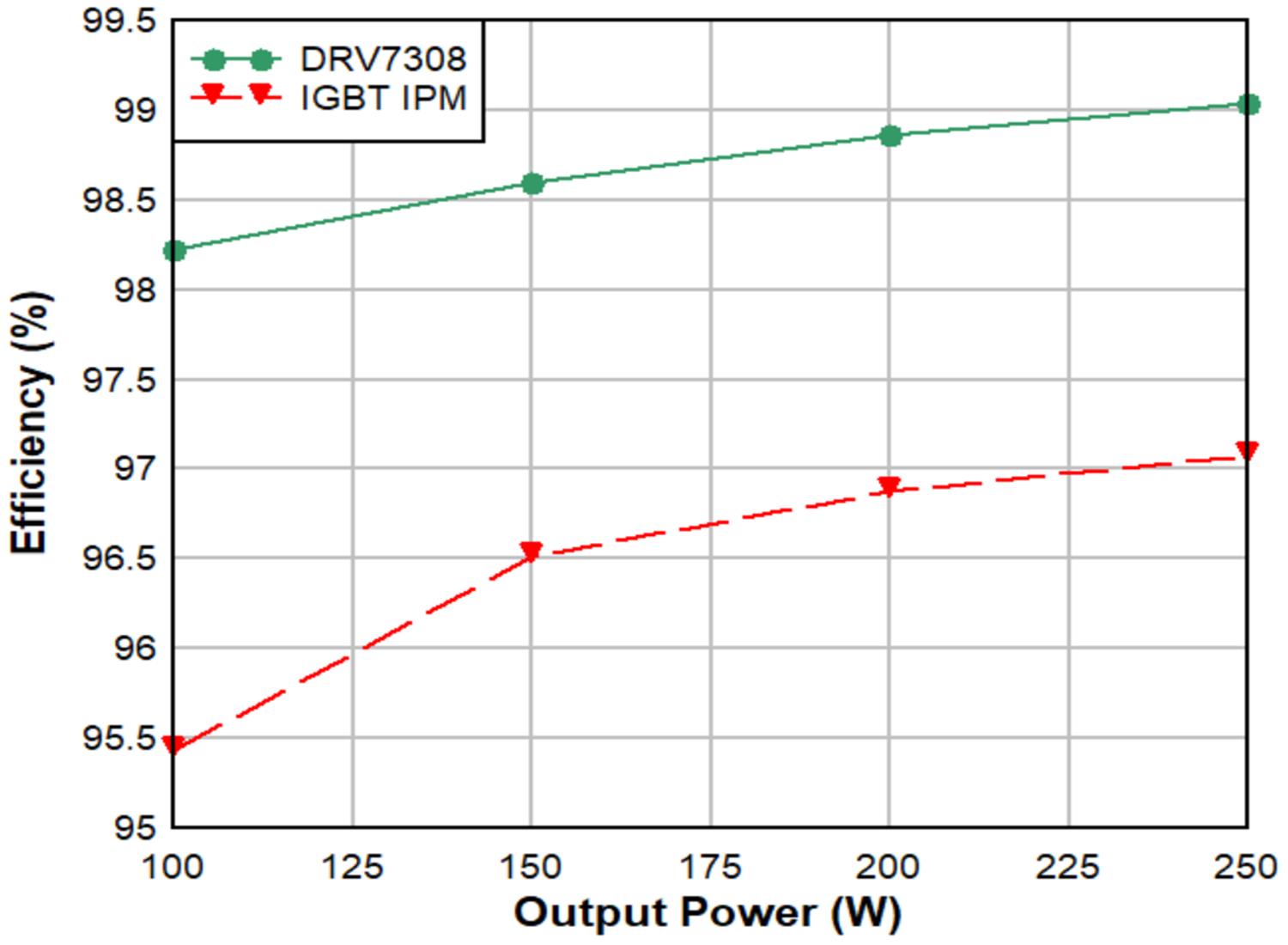

Figure 1 shows a theoretical inverter efficiency comparison between GaN-, IGBT-, and MOSFET-based solutions, revealing that the GaN solution helps reduce power losses by at least half. Figure 2 compares the efficiency of the Texas Instruments (TI) DRV7308 three-phase GaN intelligent power module (IPM) to a 5A peak-current-rated IGBT IPM with a 300VDC supply at a 20kHz switching

frequency with a fan motor that has 2m of cable at a 25°C ambient temperature, delivering 0.85A of RMS winding current and 250W of inverter output power. The slew rate of the GaN IPM is set to 5V/ns.

Figure 2: Efficiency comparison of the DRV7308 and an IGBT IPM in a 250W application

Motor performance improvement with GaN power switches

Higher current ripple in the motor winding can cause unwanted torque ripple, increased copper and core losses, and inaccuracies in the average motor current sensed during switching. While MOSFET- or IGBT-based IPMs are typically rated for 20kHz, they are normally operated at six to 16kHz because of high switching losses. GaN switches, in turn, can switch at much higher frequencies, resulting in improved motor efficiency and performance.

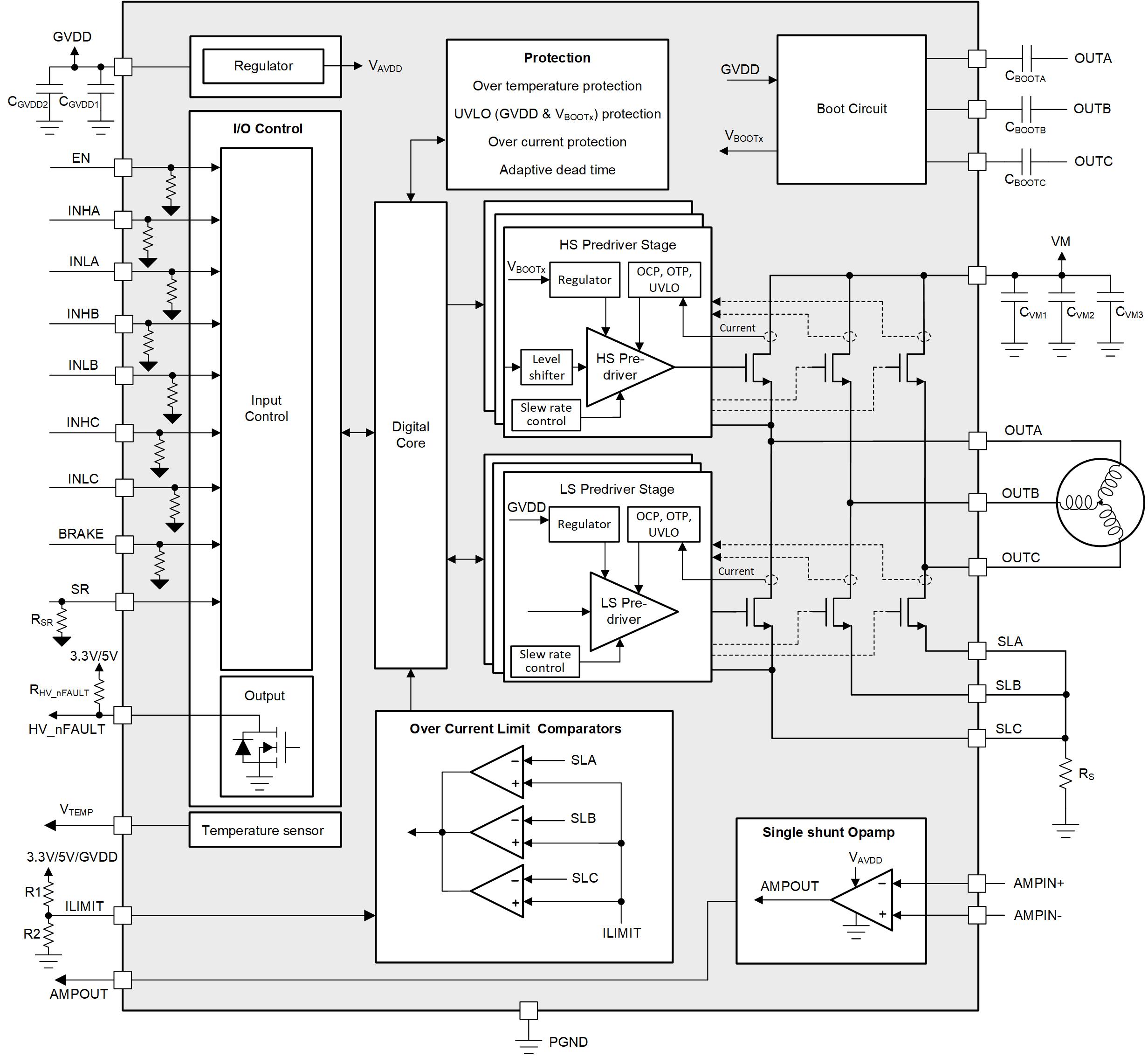

Figure 3 shows the functional block diagram of the DRV7308, which integrates predrivers for all GaN FETs with slew-rate control of phase-node voltages. The DRV7308 helps achieve more than 99% inverter efficiency for a three phase-modulated, field oriented control-driven 250W motor-drive application in a quad flat no-lead (QFN) 12 x 12mm package, eliminating the need for a heat sink.

Figure 3: DRV7308 functional block diagram

Design considerations when using GaN in motor drives

Designers often have to consider the impact of dv/dt on motor insulation, bearing lifetime, EMI, and reliability. The DRV7308 incorporates an integrated stage controlling dv/dt at the phase node. Values down to 5V/ns are possible, and the slew rate can be set to achieve an optimum trade-off between motor winding insulation and switching-loss optimisation.

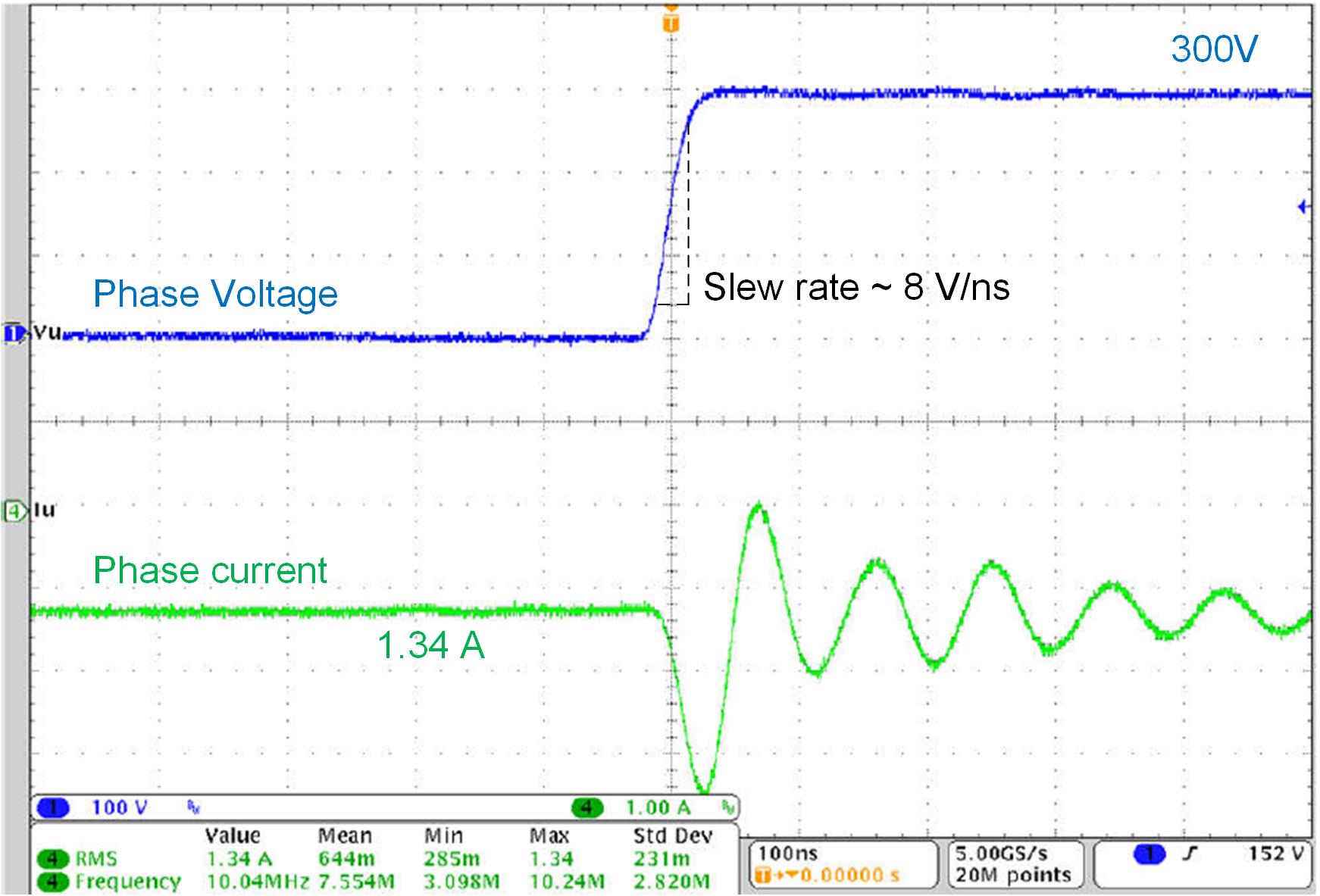

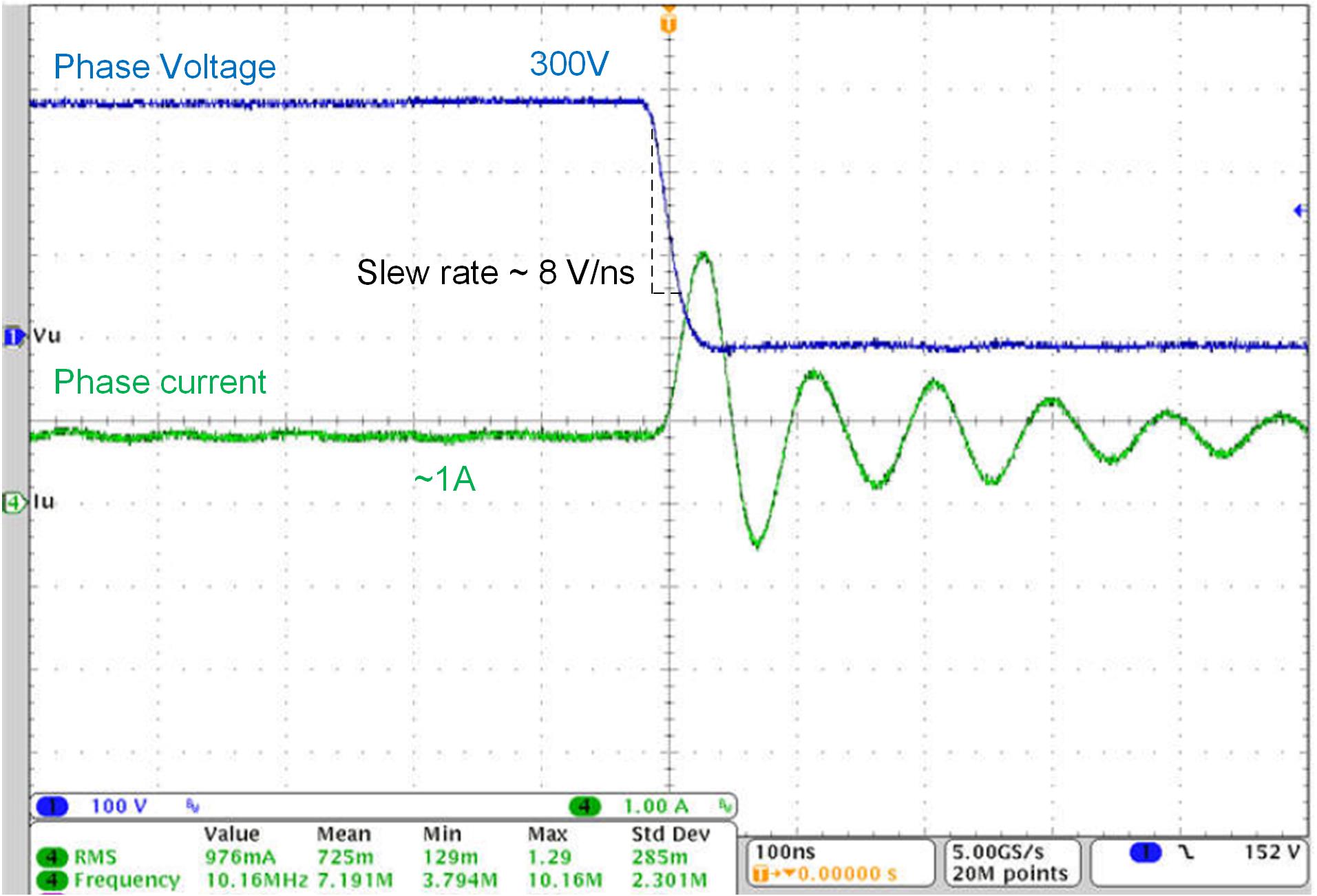

Figure 4 and Figure 5 show the phase-node switching voltage of the DRV7308 at a 1A load, at 300V, with a 10V/ns slew-rate setting and a 2m motor cable. The zero reverse recovery of the GaN FET with lower parasitics and predriver slew-rate control help achieve a clean voltage switching waveform.

Figure 4: Phase-node voltage rising slew rate with a 2m cable and fan motor

Figure 5: Phase-node voltage falling slew rate with a 2m cable and fan motor

Impact on system efficiency

Air-conditioning and refrigeration systems often need a very wide speed range to achieve the highest compressor and heating system efficiency. Traditional IPMs with more than 1μs of dead time and more than 500ns of propagation delay limit the maximum and minimum operating PWM duty cycle and reduce the operating speed range. A higher dead time also reduces the available voltage to the motor and increases the amount of motor current for the same power delivery.

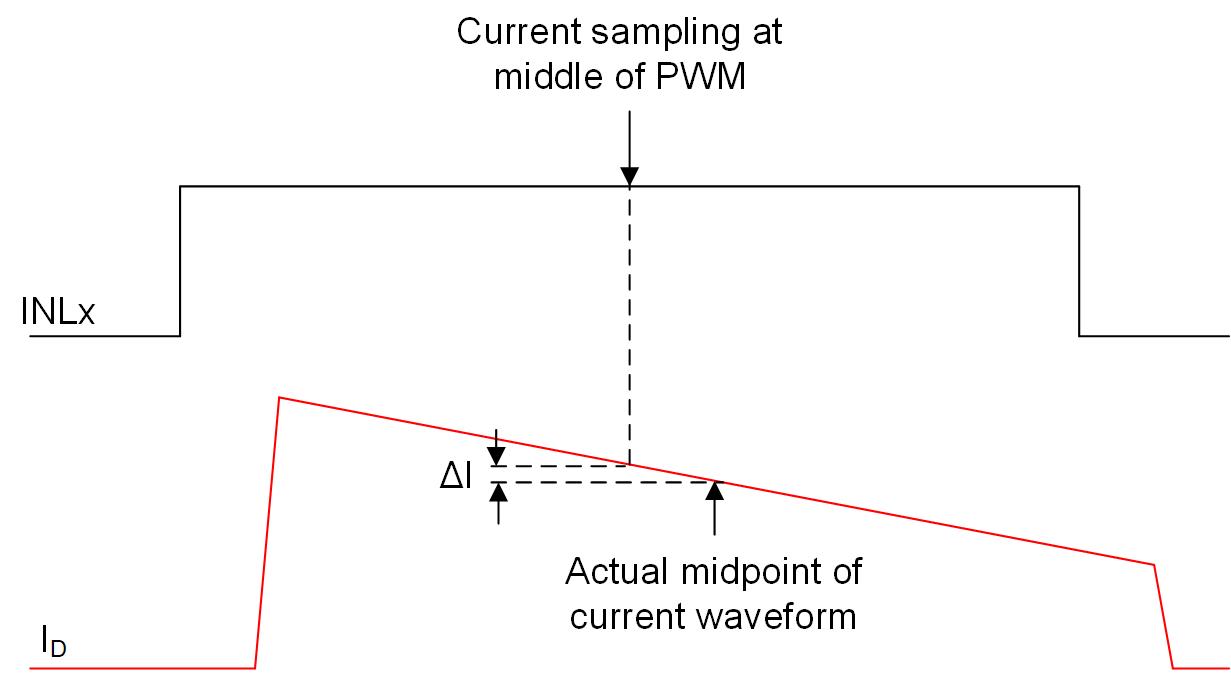

Ultra-low dead time and propagation delay – with low propagation delay mismatch – enable accurate average current sensing, resulting in increased control accuracy. Figure 6 shows the impact of propagation delay on average current-sensing accuracy. During PWM, sampling the current at the middle of the PWM on-time period will obtain the average motor current in every PWM cycle.

Figure 6: The impact of propagation delay on current-sensing accuracy

Figure 6 also illustrates how propagation delay makes the current sensing deviate from the mid value. The error in current sensing (ΔI) depends on propagation delay, applied voltage, PWM switching frequency, and motor inductance. The current-sensing error also affects motor position sensing (estimator) accuracy in a sensorless control driver, resulting in reduced motor efficiency. The DRV7308, with ultra- low propagation delay and propagation delay mismatch, helps achieve accurate average current sensing and improves motor efficiency.

Impact on audible noise

In motor-drive systems, one of the main sources of audible noise is torque ripple caused by current distortion. For a motor, current distortion depends on multiple factors, including PWM frequency, dead time, and current-sensing accuracy. The higher switching frequency enabled by the DRV7308 results in reduced winding current ripple and low torque ripple beyond the audible range. Furthermore, the DRV7308’s adaptive dead-time logic enables less than 200ns of dead time, resulting in minimal current distortion and lower audible noise.

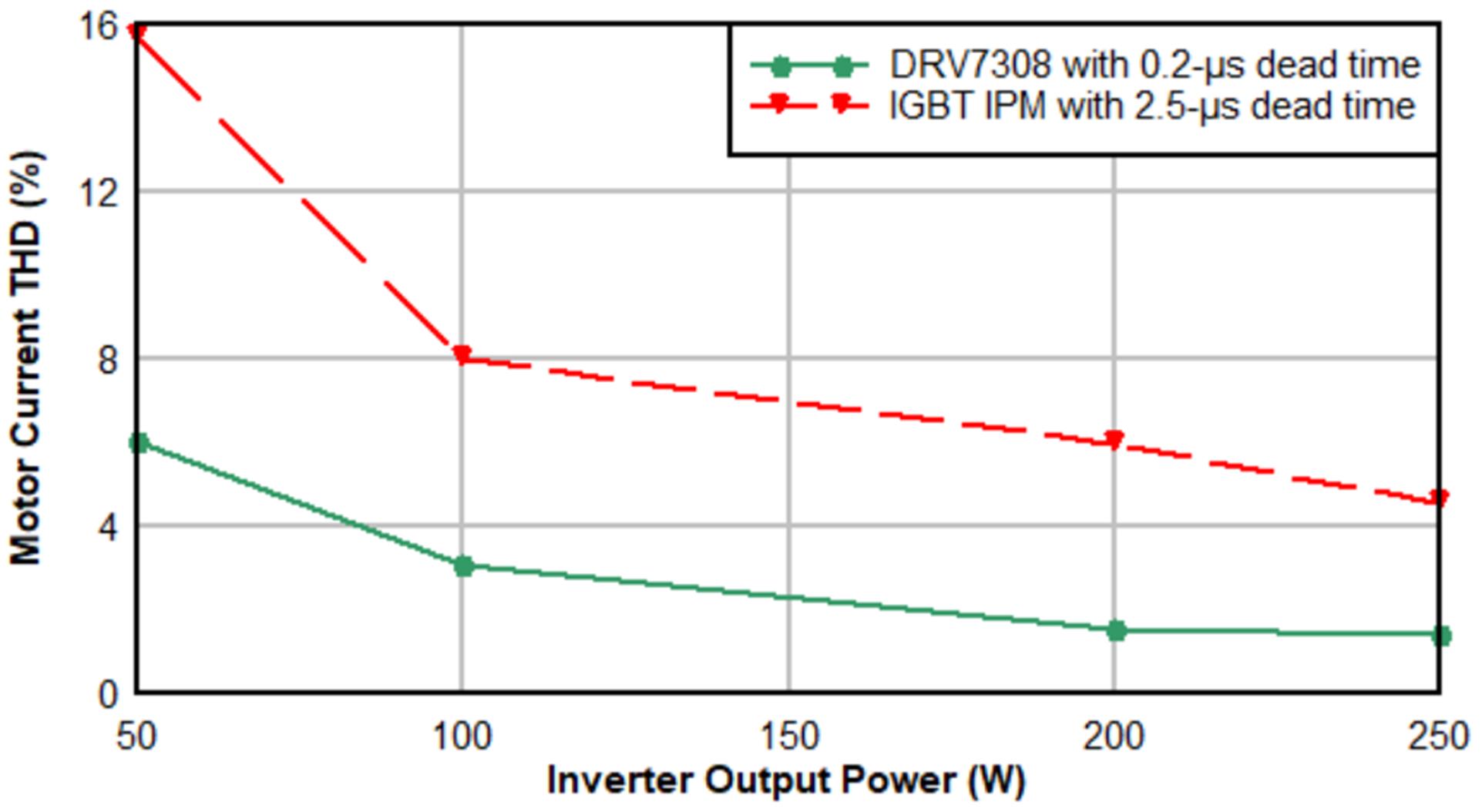

Figure 7 compares the motor winding current total harmonic distortion (THD) when testing the DRV7308 with a 0.2μs of dead time and an IGBT IPM with 2.5μs of dead time. The DRV7308 distortion is very low compared to the IGBT IPM. This distortion will increase exponentially for the IGBT IPM at lower power.

Figure 7: Motor current THD comparison with dead time

Conducted and radiated EMI

Conducted and radiated EMI depend on switching frequency, dv/dt, di/dt, switching voltage oscillations and reflections, and the loop area of the switching current. The DRV7308 incorporates multiple design techniques and printed circuit board (PCB) layout options to address EMI and EMC concerns:

- Higher switching frequencies help reduce current ripple and capacitor requirements to meet the conducted emissions

- The DRV7308 predriver can control the phase-node switching slew rate (dv/dt) to meet EMI requirements

- With zero reverse recovery and low parasitics, GaN can offer better switching performance without creating voltage overshoot and oscillations at the phase node during switching

- Figure 4 and Figure 5 show the DRV7308’s clean switching waveforms, resulting in less EMI

- Local decoupling capacitors will provide pulse currents during switching. The DRV7308 is designed such that the switching current loop area to the decoupling capacitor is minimised (see Figure 8)

Impact on solution size

Apart from the small package size and heat-sink removal, the highly integrated DRV7308 includes an operational amplifier for motor current sensing three comparators for current limiting, a temperature sensor and a suite of protective features. PCB size is thus reduced by as much as 55% compared to IGBT- or MOSFET-based solutions.

Due to this size reduction, the inverter can also be positioned close to the motor, eliminating any cabling between the inverter board and the motor, leading to reduced losses and less conducted and

radiated EMI.

Protected and reliable system designs

GaN needs faster and reliable overcurrent protection to eliminate saturation. Integrated protection eliminates the effect of parasitics and provides shorter response times in the order of a few hundreds of nanoseconds. Both the inverter and the motor need overcurrent protection to prevent any thermal runaway during overload conditions.

230VAC line-powered motor drives can provide a rectified DC bus voltage of up to 450VDC, either from the voltage tolerance of the AC line or by using active power factor correction circuits. The inverters need therefore to be designed for an operating voltage of 450V, and some motor drives must handle even higher voltages for short time spans if the motor-generated back EMF exceeds the supply voltage or in case of inductive kickback. Inverters also may need to handle higher off-state blocking voltages to account for input line-voltage surges or electrical fast transients.

The DRV7308 is designed with integrated drain-to-source voltage protection to protect the GaN FET during overcurrent events. It also has integrated overcurrent comparators for cycle-by-cycle current limiting, designed for a 450V operating voltage with a 650V off-state blocking voltage rating. Other protections monitor fault scenarios such as undervoltage, overcurrent, and pin-to- pin short circuits.

Conclusion

Advancements in GaN-based IPMs such as the DRV7308 will continue to help increase power density, power delivery, and efficiency in motor drives for appliances and HVAC systems, while saving system costs and increasing reliability.

Manu Balakrishnan, Systems and Applications Manager for Motor Drivers, Texas Instruments

Manu Balakrishnan, Systems and Applications Manager for Motor Drivers, Texas Instruments

This article originally appeared in the July’25 magazine issue of Electronic Specifier Design – see ES’s Magazine Archives for more featured publications.