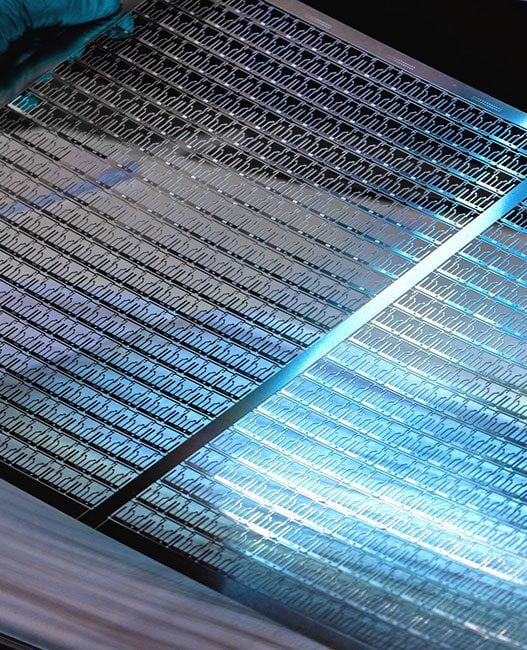

The ERSASCOPE 2 uses megapixel, digital USB 2.0 camera technology offering up to 400 percent higher resolution than previous models. Enhanced images allow for increased clarity when zooming to higher magnifications, especially when using the revolutionary flip chip optical lens.

A new metal halide light source offers a brighter white light and a mechanical iris adapter for additional gooseneck lighting with two standard fiber optic light brushes.

“We found that the ERSASCOPE 2 better enables us to find BGA quality issues such as cold soldering or solder peeling than X-ray inspection,” commented Stephen Yun, V.P. of Operations, ACME PCB Assembly. “The ERSASCOPE 2 gives our company another inspection layer to make sure the quality is excellent.”