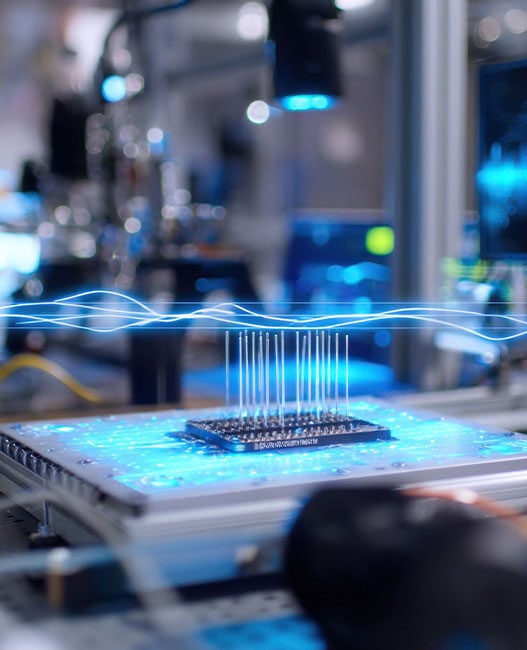

High power density 3D capacitor technology allows the storage and control of large quantities of electrical energy in microelectronic circuits. The ability to process advanced and complex ALD structures with a high dielectric constant (k) is one of the key enabling technologies in realising the low power consumption, small footprint, long-term stability and reliability that these applications demand.

“Picosun has been a pioneer in the development of ALD techniques, and has established itself as a technology leader in the processing of 3D capacitors,” said Chris Ridge, managing director of SiSTEM Technology. “We are already seeing a high demand for this equipment from the semiconductor industries for use in ICs and sensors, and for MEMS/NEMS (micro/nanoelectromechanical systems) manufacturing, as well as in protective coatings for water repellence, anti-tarnishing, wear protection, and corrosion protection. We now look forward to servicing the new applications that will result from this development programme.”

Picosun is a partner in the EU 7th Framework Programme project PICS*, of which the work for the next generation 3D capacitor production upscaling is a component.

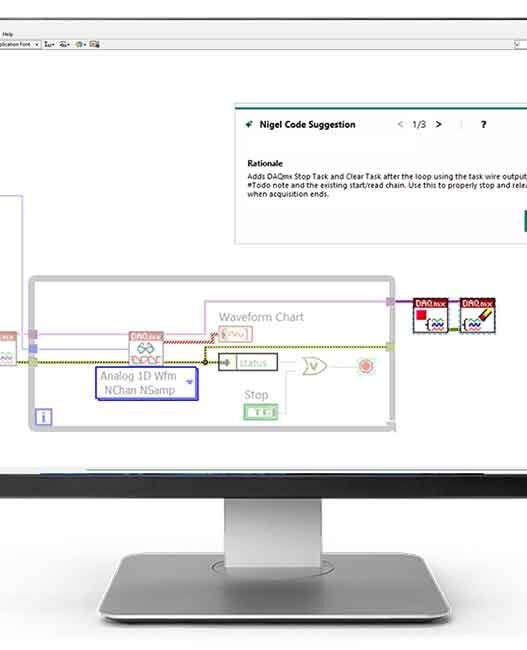

Fraunhofer CNT, a top European research centre for micro- and nanoelectronics, is a collaborative partner in this programme. “Picosun is the only company offering mature ALD batch equipment that can run either on a standalone basis or clustered using a vacuum robot, enabling production to be ramped up in a cost-efficient way,” said Dr. Jonas Sundqvist, group leader of high-k devices at Fraunhofer CNT, Germany. “We aim to transfer our proven high-k capacitor material and process knowledge to an ALD batch system from Picosun, thereby improving cost-of-ownership for applications employing thicker high-k layers for high voltage applications ‑ an offering that is not available in the market today.”