Deterministic multi-axis motor control solution

It has been announced by Microsemi that it has made enhancements to its SmartFusion2 SoC FPGA-based deterministic multi-axis motor control solution, expanding its features to support applications using encoder, Hall sensor, CAN bus and induction motors.

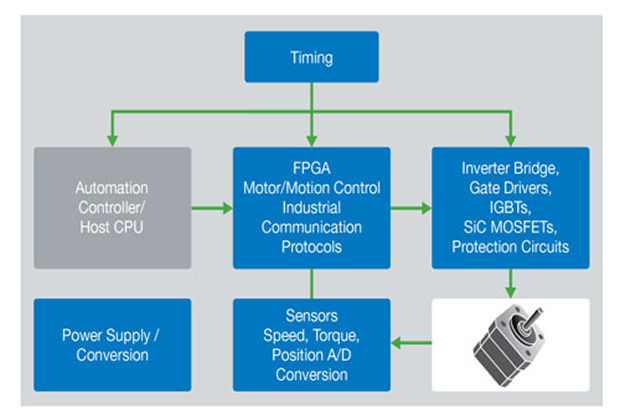

Microsemi’s motor control solution is a comprehensive development environment comprising of a fully-modular intellectual property (IP) suite, hardware kit and graphical user interface (GUI) for simplified development and debugging of the design.

The motor control solution’s modular IP suite is optimised for SmartFusion2 SoC FPGAs and IGLOO2 FPGAs, and can be easily reused and ported across designs using Microsemi’s Libero SoC Design Suite. Libero offers high productivity with its comprehensive, easy to learn, easy to adopt development tools for designing with Microsemi’s power efficient flash FPGAs and SoC FPGAs. The suite integrates industry standard Synplify Pro and Modelsim with best-in-class constraints management, debug capabilities and secure production programming support enabling users to target broad-based applications within the industrial, medical, automotive, defense and aviation markets.

“Our FPGA-based motor control solution offers many advantages over traditional digital signal processor (DSP) and microcontroller (MCU)-based solutions, as our device features deterministic response, better performance with multiple motor control, as well as the ability to integrate multiple functions and offer scalability,” said Prem Arora, Director of Marketing for Microsemi. “This high performance device can also support multiple industrial communication protocols, which are quintessential to modern drives and industrial control systems.”

The new features of the solution enable Microsemi to support various motor types and control algorithms while providing unique offerings over competitors, such as reliability, security and low power. Its enhancements enable precise alignment and speed control (position and motion sensing) and are ideal for a number of target applications including industrial/factory automation, robotic arms, 3-D printers, automotive, as well as portable medical equipment. Microsemi’s FPGA-based deterministic motor control solution is complemented by the family of sensor interface integrated circuits (ICs) based upon inductive sensing technology, including the LX3301A and the LX3302.

“The industrial and factory automation and process control market is expected to grow at a compound annual growth rate (CAGR) of 4 percent from 2015 to 2020,” said Les Santiago, Research Director for wireless and IoT semiconductors, at market research firm IDC. “Key trends driving this growth are automated factories, intelligent motion control, advances in industrial communication and wireless sensor networks.”

With high motor performance of 100K revolutions per minute (RPM), Microsemi’s newly enhanced solution is differentiated by its accurate rotor position and speed, providing precise algorithms for angle estimation in sensor less field-oriented control (FOC) applications, as well as precise torque output. In addition, source code is now available in Verilog, along with VHSIC Hardware Description Language (VHDL).

Additional key features include:

- Support for key motor control algorithms, including BLDC, stepper motor and induction motor

- Motor control algorithms implemented in an FPGA fabric

- Scalability to a multi-axis motor drive design

- Design flexibility with modular IP suite

- Integration of system functions to lower total cost of ownership (TCO)

“Our customers are asking us for a high level of functional integration and miniaturisation,” said Jonas P. Proeger, Marketing Director, Trinamic Motion Control. “The SmartFusion2 series is our platform to fulfill this demand and integrate bus building blocks like our EtherCAT slave controller together with protocol stacks and single or multi-axis motor control—all in one compact and powerful device.”