Getting started with motor control

Today’s motor control products increasingly come with a variety of supporting material, including free algorithms, to help speed up time to market. Sally Ward-Foxton reports for ES Design magazine.

For every gear-head that’s spent a year perfecting one motor control algorithm, there is also the newbie designer or non-specialist that needs more help getting started in this notoriously impenetrable field. Major vendors are making motor control more accessible by providing quick-start platforms such as development kits and free, basic algorithms to allow a head start when getting a motor design up and running. There are several ways for manufacturers to help less experienced designers succeed first time.

NXP’s concept for simplifying motor control is to allow the use of the same control IC for different motor types, and even for more than one motor. The company recently debuted its LCP1500 series of motor control ICs (Figure 1), all of which can control a variety of types of motor, including sensored and sensorless. This series is optimised for brushless DC (BLDC) and permanent-magnet synchronous motors (PMSMs), but it can also drive AC induction motors (ACIMs). The flexibility of these micros mean they can even control more than one motor simultaneously, provided the demand for the 72MHz ARM Cortex-M3 core is not too high.

Figure 1 - NXP’s LCP1500 series can control a variety of types of motor, including sensored and sensorless types. This series is optimised for brushless DC (BLDC) and permanent-magnet synchronous motors (PMSMs), but it can also drive AC induction motors (ACIMs).

“We see a lot of heating, ventilation and air conditioning applications that use one motor control chip for the fan motor and one for the compressor motor,” explained Ross Bannatyne, General Manager, Mass Market Microcontrollers, NXP, illustrating a potential market for the LCP1500 series. He added that this feature will also benefit other large home appliances, as well as industrial applications like pumps and generators.

A Quadrature Encoder Interface (QEI) is included to enable control of motors which use position sensors to determine the position and speed of the rotor, like those common in AC induction motors. A typical setup using a two-channel encoder would convert displacement into a pulse signal, and by using the relative phases of the two signals, track the position, direction and speed of rotation of the rotor. The QEI gathers and make sense of this information without disturbing the CPU, conserving processing power for more complex tasks.

The LCP1500 series can also control sensorless systems, which typically work by measuring the back EMF (electromotive force) from the motor. These systems usually have a larger requirement for processing power as a more complex algorithm is necessary. However, motors without sensors can be made smaller and cheaper, so there is a tradeoff at play. Whether a sensored or sensorless motor is chosen for the design, the same control IC can be used, simplifying the design process.

Analogue subsystem

The LCP1500 also features two 12-bit, 12-channel, 2Msps ADCs with 500ns ADC conversion time. Each ADC supports two independent conversion sequences, and the ADC conversion clock can be the system clock or an asynchronous clock derived from one of the devices’ three PLLs. Four SCTimer/PWM timers provide up to 28 PWM channels (with average PWM resolution of less than 1ns) in a tightly coupled analogue and timing subsystem.

This analogue and timing subsystem is at the heart of the device’s ability to control more than one motor at the same time. According to Bannatyne, it is possible to control more than two motors simultaneously, depending on how many ADC and PWM channels are used for each motor. A typical implementation might use three ADC channels for the back EMF input from a sensorless motor, plus two more for other temperature, voltage and current monitoring, so five in total. It would also use six PWM channels. In this example, the LCP1500 could control four motors comfortably, provided the algorithms are not too complex for the CPU to handle, he says.

The devices include four fast comparators (68ns propagation delay), which are necessary to implement safety features such as short circuit protection and over-current/voltage monitoring. Connectivity features include CAN for industrial applications and USB capability for easy field updates.

Free firmware

For those designers not experienced in motor control, NXP offers free firmware for controlling sensored and sensorless PM and BLDC motors. The control algorithm provided has a very small footprint, taking up only 10k of flash, and it runs in just 40μs. Using this code, it’s possible to get up and running very quickly.

Also offered are GUI-based calibration and tuning tools. The need for calibration of motor control systems stems from the fact that all motors are different, exhibiting unique characteristics, such as inductance. The motor control algorithm must therefore be retuned once the control IC is paired with a specific motor as part of the system. The NXP solution makes this quick and easy to implement via the GUI.

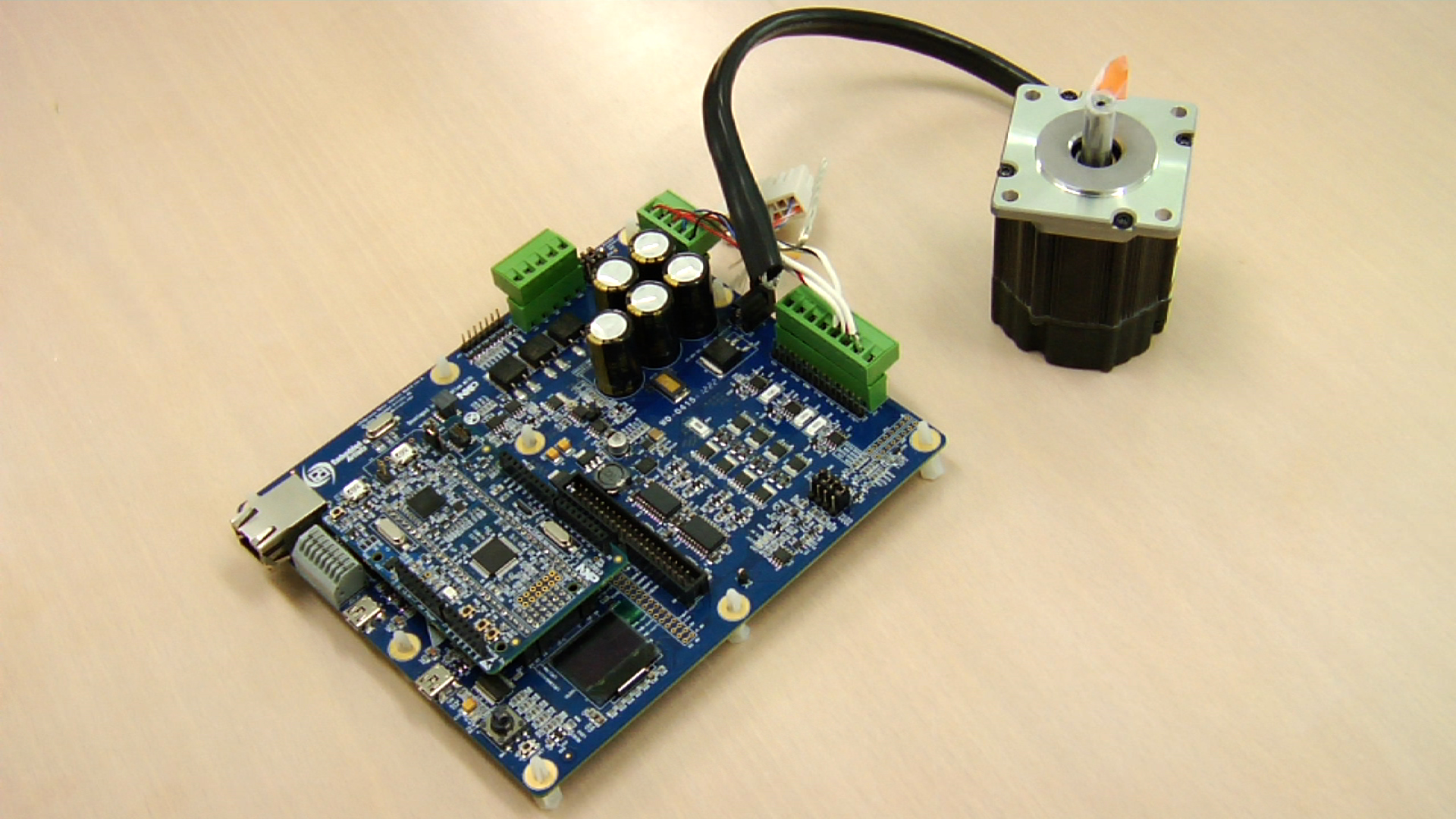

Figure 2 - Two motor control ‘solution boards’ based on the LCP1500 series are available from NXP, which include baseboards, motor and free firmware.

Developers can choose from the free NXP LPCXpresso development platform, incorporating a full featured C/C++ toolchain and IDE, or from other popular tools such as those from Keil and IAR. Two motor control ‘solution boards’ are available (Figure 2), which include baseboards, motor and free firmware. One demonstrates control of sensored and sensorless PM motors, the other demonstrates classical trapezoidal motor control functionality on a sensored BLDC motor.

Under one minute

On a similar theme, Renesas has developed two new inverter kits that are apparently so easy to use, a permanent magnet AC motor can be rotated in under one minute.

Tuning the software to the application requirements can take some time, especially for complicated sensorless field-oriented algorithms, which can accurately control the motor’s speed and torque. Renesas’ algorithm uses flux weakening in order to achieve rotation speeds higher than the nominal speed of the motor. The kits can auto-tune the current proportional-integral (PI) coefficients (Kp, Ki) and identify intrinsic motor parameters (Rs, Ls, Lm), in order to help get designs up and running quickly by eliminating the need to manually calculate these tuning algorithm coefficients.

The kits have a reference design for the sensorless control algorithm pre-loaded and a GUI helps engineers drive their own motors with just a few clicks. The GUI also provides real-time visualisation of the motor phase, current and step response.

Figure 3 - Renesas’ motor control kit, based on the RX220, can provide 50 DMIPS and is optimised for equipment that needs medium dynamics but is also cost-sensitive.

Both kits are based on Renesas’ 32-bit RX family of MCUs. The first, based on the RX220 (Figure 3) can provide 50DMIPS and is optimised for equipment that needs medium dynamics but is also cost-sensitive. The other is based on the RX62T, which offers 165DMIPS and provides the dynamics required to drive motors with a high level of accuracy. This MCU integrates six operational amplifiers, six comparators, a floating point unit and two timer units to drive two 3-phase motors simultaneously.

Each kit contains the YROTATE-IT inverter board, a 24VDC permanent magnet AC motor, a CD-ROM including the embedded software source code, the PC GUI, the board schematics, the bill of materials, Gerber files, user manual, quick start guide and the power stage schematics/Gerber files.