New report reveals a promising market

For many years now, the semiconductor industry development has been governed by the Moore’s law and the increasing demand for higher performance and lower manufacturing costs. Under this context Yole Développement (Yole) has identified a strong interest for panel packages technologies.

“At Yole, we saw a growing enthusiasm for panel packages solutions dedicated to a selection of advanced packaging platforms,” commented Amandine Pizzagalli, Technology and Market Analyst, Advanced Packaging and Semiconductor Manufacturing at Yole. She added: “The panel packages market is a competitive market which is attracting a lot of new entrants compared to the existing advanced packaging market segments.”

Under the new advanced packaging analysis entitled ‘Status of Panel-Level Packaging & Manufacturing’ released by Yole last November, the market research and strategy consulting company estimates the panel packaging industry will reach $109m by 2017, with a market value of $405m by 2020.

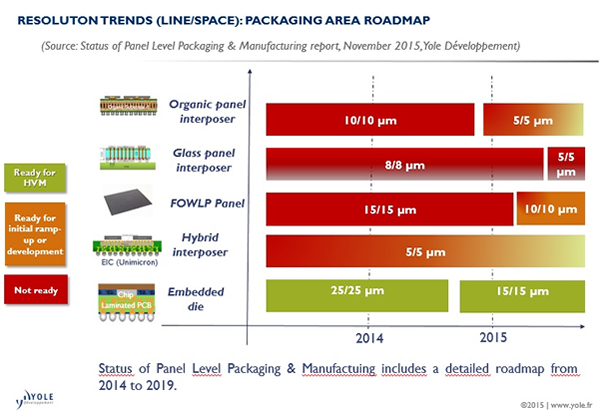

The aim of Yole’s report is to provide an overview of the panel package technologies available right now and in-development. The analysts detailed in this report the panel package solutions for the following advanced packaging platforms - FOWLP panel, embedded die, hybrid interposer and interposer (silicon, glass and organic).

For each segment, Yole’s team described the commercial status, the market adoption and the key related applications. Analysts also identified the players for each technology and their market positioning all along the supply chain. They proposed a description of the competitive landscape as well as related market metrics.

For more than four decades, the semiconductor industry has rigorously followed Moore’s Law in scaling down CMOS technologies. However, a huge investment in new lithography solutions is required to achieve advanced nodes in a range of 20nm. Although some packaging platforms processed on wafer, i.e. silicon interposer, exhibit good performance, high cost is still the main obstacle that limits its adoption for high volume manufacturing.

“The demand for lower cost with higher performance has driven the semiconductor industry to develop innovative solutions,” commented Santosh Kumar, Technology and Market Analyst, Advanced Packaging and Semiconductor Manufacturing at Yole. He added: “One new approach to reducing overall cost is to switch from wafer to a larger size panel format. Indeed, the panel infrastructure has attracted considerable interest from the semiconductor industry and is certainly a promising market due to its cost advantages and economy of scale benefits.” Panel level manufacturing has the potential to leverage the knowledge and infrastructure of WLP and the PCB /Flat-Panel Display/Photovoltaic industries.

To perform this new analysis, Yole’s experts gathered valuable information at multiple levels of the supply chain - they interviewed advanced packaging leaders including device manufacturers in both volume production and development stages; they also debated with equipment and materials suppliers to get a wide vision of the panel package technologies and to understand the technical and market issues.

Under this approach, the market research company highlighted the key insights of this industry and details the range of applications. “Panel’s application scope could be segmented into three categories defined by the required resolution,” announced Amandine Pizzagalli from Yole.

• High-end products like networks, CPU /GPU , FPGA , and servers will necessitate a resolution reduced to 2µm. Therefore, this area is likely to be dominated by 300mm lines where the front end is already well established and has the L/S capability to achieve such resolution.

• Midrange products including basebands, processors, power management modules and RFIC should be the main target of FOWLP based on panel and glass panel interposers.

• And organic interposers should be restricted to low end products - mobile, consumer, WiFi, and power management.

Business is there for the taking, but how do you design the ideal supply chain to support high volume manufacturing? Yole’s report provides an analysis of the panel industry, its future development and related drivers covering platforms such as FO WLP panel, embedded die, organic interposer, glass panel interposer and hybrid interposer. Yole and its advanced packaging team, are closely studying and monitoring the industry’s activities in the advanced packaging field. Yole’s vision will be presented during the European 3D TSV Summit 2016 taking place in Grenoble, France, from 18th-20th January 2016.