The world's first pneumatic endoscope manipulator

In August 2015, Riverfield will begin selling the world's first pneumatically controlled surgical assist robot that can smoothly manipulate endoscopes to increase a surgeon's control and precision. Riverfield, a Tokyo-based venture company launched by the Tokyo Institute of Technology (Tokyo Tech) and Tokyo Medical and Dental University (TMDU), has built a compact, lightweight and easy-to-use surgical assist robot called EMARO.

EMARO will be marketed by Tokyo-based Hogy Medical, Japan's top maker of medical equipment. EMARO is the result of more than 10 years of research on pneumatic, ultra-precision manipulation by Associate Professor Kotaro Tadano of Tokyo Tech's Precision and Intelligence Laboratory and Professor Kenji Kawashima of TMDU's Institute of Biomaterials and Bioengineering.

Minimally invasive operations are rapidly gaining popularity over traditional surgery as they promise rapid post-operative recovery and leave much smaller scars. Particularly popular are operations that employ endoscopes.

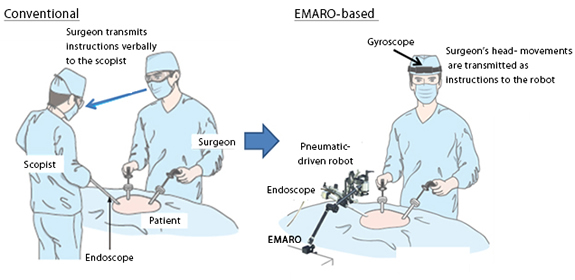

An endoscope-based surgical operation requires a second doctor to serve as scopist, one who is skilled at controlling the device. Such surgeries present unique risks, such as communication difficulties between the operating surgeon and the scopist, or camera shake. New equipment is needed that can overcome these problems. At the same time, conventional motor-driven endoscope manipulating robots are not ideal in terms of operational subtlety and delicacy, paling in comparison with pneumatically driven models.

EMARO controls the endoscope by sensing vertical and horizontal movements of the surgeon's head, through a gyroscope that is worn on the forehead. The endoscope has four degrees of freedom for movement: forward and backward (insertion and removal), up and down, left and right, and rotation. The surgeon directs this motion by controlled movements of his head and by operating switches with his feet.

Until now, pneumatic manipulation technologies have not been able to provide the smooth and continuous movement needed for highly precise control of surgical devices. Professors Tadano and Kawashima overcame this hurdle by creating an advanced model with continuous air pressure control and an original manipulation technique. Their success owes much to Tokyo Tech Professor Toshiharu Kagawa, who had scored impressive results over decades of research in the field of fluid measurement and control.

Pneumatic driving makes it possible for robots to move gently and smoothly. It has been used extensively in industrial robots, particularly for grasping and holding objects. Moreover, the pneumatic approach makes it possible to create a compact and lightweight design; sufficient power can be obtained by injecting or extracting air through a cylinder no larger than a standard syringe - about 10mm in diameter.

Consequently, the operating surgeon can receive clear endoscopic images without camera shake, resulting in more precise surgeries. Also, EMARO, taking the role of a scopist, can be useful in smaller hospitals that have a shortage of doctors, allowing more patients to undergo laparoscopic surgery.

EMARO is the first in a series of surgical assist robots that will use ultra-precision pneumatic manipulation technology. Development is now underway for a system that uses the pneumatic drive design and incorporates forceps. As its primary feature, this system will be able to detect the force exerted on the forceps through air pressure, and will feed this sensory information back to the operating surgeon. This is called force sensing.

With surgical assist robots, the surgeon sits in front of a console placed off the patient, and operates the controls with both hands. While observing endoscope images, the surgeon can manipulate forceps and the endoscope. With force sensing, the surgeon will feel as if he were directly working on the patient, which is likely to help improve surgical accuracy.