Redefining the notion of sensors

Sensors have long been a part of electronic systems in practically every industry. They are so fundamental to the operation of these countless systems that it is hard to imagine life without them. Janusz Bryzek, an executive from Fairchild Semiconductor, said that sensors could reach 1 trillion per year and become 15% of the global gross domestic product by 2024.

Author: Noah Reding - Product Manager, Automotive and Aerospace Networks at National Instruments

For decades, sensors have been used to quantify physical phenomena while serving as catalysts to improve decision making, whether by an engineer or an embedded control system. However, many industries have been forced recently to expand their belief of what a sensor is. As industries continue to adopt the philosophy of more software in embedded controllers and as embedded system electronic complexity grows at an exponential rate, these systems are forced to take input from new devices to enable key features and capabilities. The previous notion that sensors only measure temperature, strain, force, and other basic data points is obsolete. Now engineers consider sensors as inclusive of all of these measurements plus additional technologies like RF signals, images, audio, and video. Furthermore, test engineering departments face the daunting challenge of developing complete test systems for these complex devices. As market expectations rapidly change, engineers are constantly working to understand new technologies and must adapt just as quickly as their devices under test do.

More expectations create more challenges

Some of the clearest examples of this challenge are in high-volume, consumer-facing markets like automotive and telecommunications. In this space, consumers, suppliers, and even legislative bodies have high product expectations.

Consider the automobile. In the past, sensors were used to monitor key data points like engine temperature and oil pressure, but because of the incredible rise in consumer and legislative demands, car manufacturers have been forced to significantly increase their cars’ electronic components and capabilities. Today, vehicles are required to control their emissions, correct dangerous human driving behaviors, receive satellite radio signals, and provide a level of entertainment and convenience to passengers. To accomplish all of this, engineers must expand their idea of a 'sensor' to parts like O2 sensors for catalytic converter output, cameras for monitoring the driver’s eyes, an antenna for picking up satellite radio and navigation signals, and a display for video and information communication.

The mobile phone industry is no different. For example, a mobile phone is projected to have nearly 20 MEMSs/sensors in 2015 compared to two sensors in 2000. The current design of the Samsung Galaxy S4, launched on March 13th, 2013, has 10 sensors to detect gestures, proximity, rotation, acceleration, geomagnetic field, temperature, humidity, barometric pressure, and light. This trend in sensor growth has led to new sensor-based 'apps', which will continue to drive demand for new sensors in future mobile phone designs. Just like a modern vehicle, the mobile phone continues to evolve quickly, resulting in new types of I/O and physical phenomena being used as 'sensors'.

Implications for test

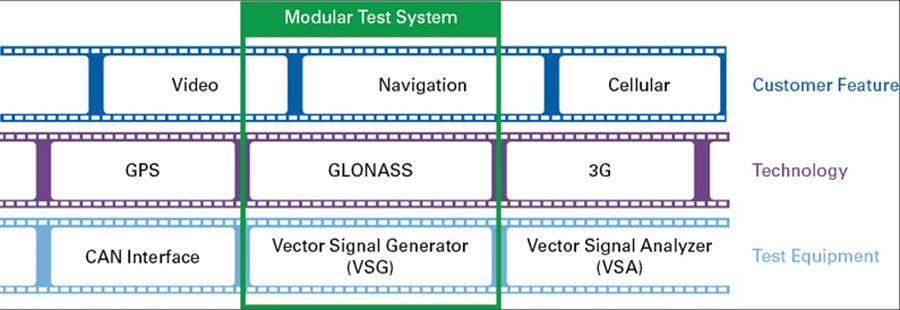

Capital costs of automated testers can account for more than 60% of the overall test costs, so minimizing hardware changes can significantly reduce overall costs. For example, a dedicated test solution that addresses mobile devices, which have a typical shelf life of 18 months, has obsolete sensors and technology for every new design. Architecting a test system that can adapt to changes occurring once or twice a year requires an agile or proactive test approach. Unlike an ad hoc approach with dedicated box instruments that specialise in one specific measurement, a proactive test approach features modular hardware and anticipates technology changes. A modular approach minimises the sustaining cost of a tester with incremental changes instead of whole product replacement.

In addition to a modular test system architecture for adding and removing instruments as needed, engineers require reconfigurable hardware that helps them use the same instrument for different and evolving project requirements. This is evident in automobiles with global navigation satellite system receivers like GPS and GLONASS. If an automotive OEM wants to sell vehicles in the United States and many other parts of the world, the vehicle’s navigation system must be able to receive and interpret a GPS signal in all of these locations. The typical test process for these systems is to generate a simulated GPS signal for the vehicle’s electronics and analyse how they respond. However, with the continued adoption of different navigation systems, like GLONASS in Russia, these same OEMs must test for multiple navigation signals, depending on the markets they want to penetrate. Having an RF signal generator that they can adapt to simulate both GPS and GLONASS signals helps OEMs get the most out of their capital investment in test systems and helps future proof AA at least part of their equipment.

A platform approach for rapidly changing technology

Tom Pierce, Vice President and General Manager, Test and Measurement Business, Honeywell Sensing and Control recently said: “In the future, people are going to put sensors in places we never have thought about. The need for sensors is exploding and there are many more potential sensor applications than we could have ever predicted.”

If the vision of a trillion sensors by 2024 is true, product will reduce total cost of ownership and improved redesign complexity will be growing and changing at a significantly more rapid pace than the current trajectory. This trend will continue to impact test organisations as more frequent product redesigns dramatically affect the total cost of test. Companies that use a test strategy featuring a modular approach that can accommodate the changing sensor market will reduce total cost of ownership and improve redesign time to meet more stringent time-to-market demands.

Caption: A modular test system provides flexibility to match customer features to the proper technology and the ideal test equipment.

View the Sensor Fundamental Webcast Series