Force sensing broadens its application horizons

Peratech’s force sensing technology is moving from the lab into consumer products and beyond. By Sally Ward-Foxton. British startup Peratech, whose QTC force sensitive material allows force sensors to screen print onto a range of substrates, is starting to see its first QTC-enabled consumer products on the market. Following investment in 2014, a new executive team was brought on board and the company’s business model changed from licensing their IP to creating and selling products for consumer electronics devices.

“We brought on an expanded group of people that have a good understanding of how to make high volume products,” said Chief Commercial Officer Mike Levin. “We now have a team that works just on manufacturing and getting quality in place. We’ve also expanded our sales team, primarily in Asia (Hong Kong, Korea, Japan and China). And rather than just licensing the technology, we are actually making the sensors, and in some cases, an integrated module with a microprocessor and firmware with host side software.”

Up close with QTC

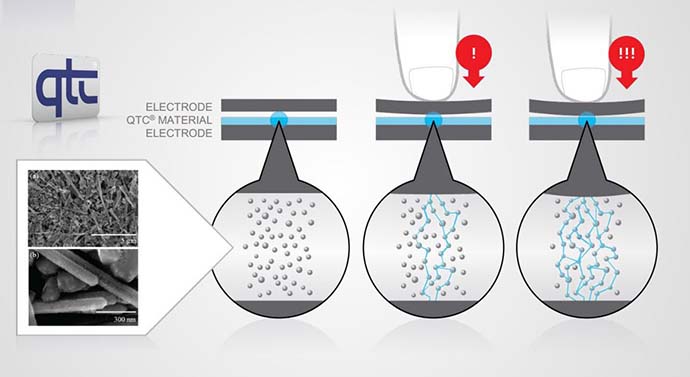

The company’s force sensing technology is based on a force sensitive material it calls QTC. QTC reduces its electrical resistance when mechanical pressure is applied, and it is sensitive enough to respond to a light finger press. The material itself is a combination of conductive and insulating materials which are primarily titanium dioxide sphere and rod shapes, suspended in a carrier material which means it can be screen printed into different sensor shapes (see Figure 1).

Above: Figure 1. Peratech’s QTC material decreases its resistance as pressure is applied

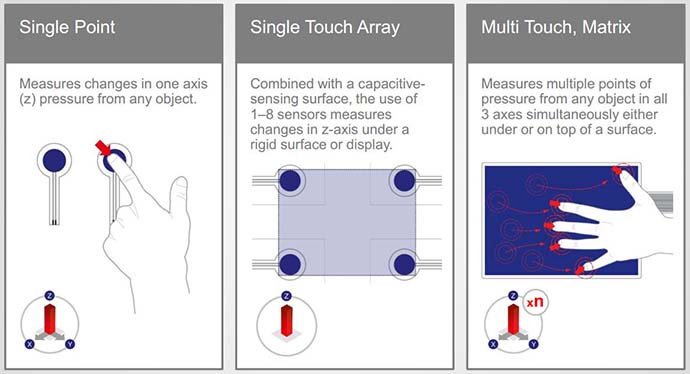

While most QTC sensor products are custom designed, they come in three broad types. “Our sensor products range from single point sensors to matrix sensors, with four-wire sensors that are an analogue variant of the matrix sensor,” Levin explained. “The matrix has discrete junctions or intersections, whereas the four-wire sensor is a larger surface that measures the differential between the edges, giving you x and y position plus force that way. And we can mix and match those, perhaps printing a four-wire sensor and a single point sensor on the same substrate.”

Initial applications for Peratech’s technology primarily involve displacing older switching technologies, replacing ‘dumb’ membrane switches and the like with something that is both a switch and a force sensor, that is, it can detect not only when the user presses the switch but how hard they are pressing. QTC is not unique in this market - there are several other sensing technologies that offer this kind of functionality, including capacitive pressure sensing, micro-strain gauges and piezoelectric/piezoresistive technologies.

“Our technology is most similar to piezoresistive,” said Levin. “Piezoelectric sensors are charge-based, they respond to dynamic changes but can’t sense static pressure because they lose charge, or drift, over time. Piezoresistive is fairly comparable in terms of speed and sensitivity, but we believe we have some advantages in terms of environmental performance, stability over temperature and time, and a less expensive material and sensing circuit.”

Above: Figure 2. Types of QTC force sensor

Consumer

Targeting the consumer electronics sector, Peratech has also made technical advancements recently. In the past, the company used PET material as the substrate for its standalone sensors, which the QTC ‘ink’ was printed on to form the sensor. For it to be stable, two fairly thick layers had to be used, typically 75 or 100 microns each, plus the electrodes and layers of ink. The total stack was almost 300 microns in total.

“We started using polyimide substrates this year which are much more stable, so we can use much thinner layers,” Levin said. “We can now use 12 or 25 micron polyimide, so the thickness of the whole sensor is now under 100 microns.”

This is particularly beneficial for mobile phones where every fraction of a millimetre in thickness counts. Other improved sensor properties are reduced shrinkage/expansion characteristics under temperature cycling, and improved flexibility. This means it can be used on curved and flexible surfaces, including flexible displays.

Real life applications for Peratech’s technology are starting to emerge. Swiftpoint, a computer interface company based in New Zealand, showed a full featured gaming mouse at CES that uses Peratech technology to make the two main buttons force sensitive (see Figure 3 - top). This capability allows gamers to control analogue functions in their games, perhaps something like the accelerator and brake pedals in a driving game, by applying varying levels of force to the mouse buttons.

“Gamers or computer users can also set their own thresholds,” Levin said. “You can set what level of force is required for initial activation, but you can also set multiple thresholds to select different things or for analogue control - in a first-person shooter, for example, with one mouse button, you can pull up your scope to zoom in, and then fire with a harder press.”

The mouse uses two Peratech PET single point sensors under the two main buttons (one under each button) to detect how hard the user is pressing. Levin points out that outside gaming, the force sensitive mouse could be used for scrolling or zooming, or selecting a word, line, paragraph or page of text with different levels of pressure.

Fingerprint sensors According to Levin, Peratech is currently working with several fingerprint sensor manufacturers to add its force sensing technology into fingerprint sensors for smartphones. Peratech’s sensor can replace the mechanical switch that is normally required (like the iPhone’s home button, for example), meaning there is no need to cut a hole in the front or side of the phone chassis. This can help manufacturers with mechanical robustness of the phones and even waterproofing, but there is another advantage. Force sensing also allows the fingerprint sensor ASIC to read the fingerprint more accurately, as it can read data when the press reaches a certain force level, rather than taking several images and determining which is the best one to use.

According to Levin, Peratech is currently working with several fingerprint sensor manufacturers to add its force sensing technology into fingerprint sensors for smartphones. Peratech’s sensor can replace the mechanical switch that is normally required (like the iPhone’s home button, for example), meaning there is no need to cut a hole in the front or side of the phone chassis. This can help manufacturers with mechanical robustness of the phones and even waterproofing, but there is another advantage. Force sensing also allows the fingerprint sensor ASIC to read the fingerprint more accurately, as it can read data when the press reaches a certain force level, rather than taking several images and determining which is the best one to use.

“Your finger changes shape as you compress it - with force information, you can get a more accurate time-based image which can help with reducing rejection,” said Levin. “You can also use force sensing for different levels of activation on the switch, for example, a light press might bring up notifications, but a hard press might unlock the phone, or something like that.”

Fingerprint sensors are usually mounted on a flex circuit which folds over behind the sensor and connects to the phone main board (see Figure 4).

“We are teaching fingerprint module companies how to integrate our sensor with their existing flex circuit,” Levin said. “We can put our electrode pattern onto that flex circuit tail, keeping additional thickness to a minimum, and there are already traces there which can go back to the ASIC or the main board.”

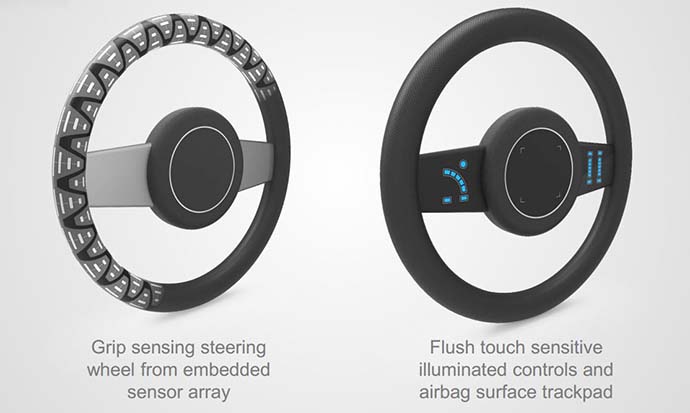

Future applications that Peratech is hoping to break into include the automotive sector. The company is currently undertaking a research project with a major vehicle manufacturer which integrates force sensing technology into the steering wheel (see Figure 5).

“The primary use case is as we get more autonomous with assisted driving capability in vehicles, you want to know when the car should be in control and when the driver should be in control,” Levin said. “To change between the autonomous mode and manual mode, the system needs to be sure that there is someone holding the steering wheel at that point.”

Above: Peratech’s concept for a force sensitive steering wheel

Above: Peratech’s concept for a force sensitive steering wheel

Other possible functions could respond to squeezing the wheel or holding it in certain positions, or even integrating controls into the steering wheel spokes or a touch pad on the centre section.

Peratech plans to eventually enable a wide variety of force sensitive surfaces, with QTC material printed onto many different types of substrates. The material can sense pressure applied from outside the equipment’s chassis or case, whether it’s metal, plastic or even wood. This can be used to enable the sleek look of modern consumer electronics in remote controls, white goods and power tools. In the mean time, QTC development kits are available.