Healthy prognosis for capnography

The use of digital SMD gas detectors can transform the development of capnography kits. For those unacquainted with capnography, this innovative process is a clinical method of measuring and monitoring the concentration (or partial pressure) of CO2 in the respiratory gases of patients. To detect CO2, capnography system manufacturers around the world rely on infrared gas sensors.

In this article Andrew Wallace, CEO of Pyreos, the Edinburgh-based supplier of pyroelectric and mid-infrared sensor technology in gas detection, motion sensing and spectroscopic analysis, sets out some of the key attributes required of these process-critical detectors.

Within the capnography process, CO2 concentration measurements take the form of a temporally well-resolved waveform, or capnogram. The amount of CO2 as a function of time can be analysed further to provide information about existing lung or respiratory diseases, including COVID-19, or as a diagnostic method in medical and emergency procedures.

System design considerations

There are many design considerations that contribute to the creation of a successful capnography system, including tolerances, tube surface quality, tube size and variations in tube material. However, when devising a system suitable for volume manufacturing, infrared detector speed is particularly important to achieve a good temporal resolution of the measured CO2 concentration waveform.

A successful design also relies on understanding that the most critical information gathered from a capnogram is the so-called end-tidal CO2 (EtCO2), the partial pressure at the end of the exhalation process. Typically, a healthy person should produce a waveform represented by a quasi-square function. By analysing deviations from that shape, it is possible to learn about any existing pulmonary diseases, the patient’s state, as well as diagnostic or procedural problems, such as incorrect patient intubation.

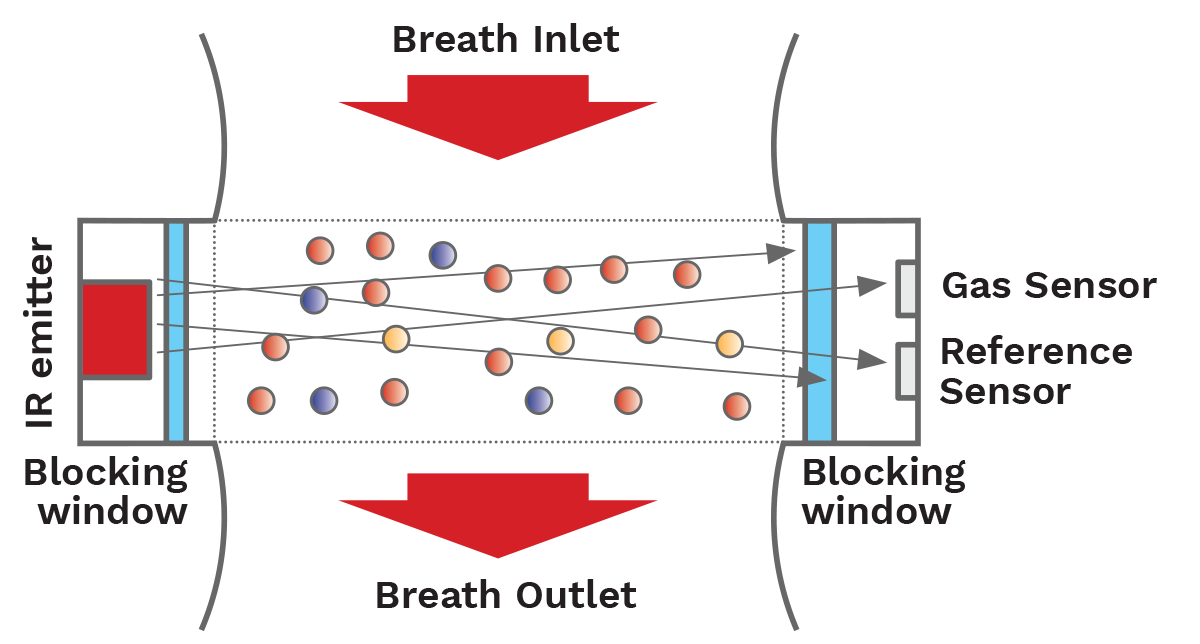

There are two main system designs used for capnography: side-stream and main-stream. Both use an NDIR spectroscopy method for measuring CO2.

Mainstream capnography

In a mainstream capnograph, the measurement of exhalation takes place directly in the breath stream, which contrasts to partial measurement in the side-stream method. This direct measurement allows for a better pronounced and real-time signal, since more CO2 is present and the distance from the patient to the NDIR spectroscopy device is minimal.

Main-stream capnographs are compact and direct measuring devices. These systems are better suited to high volume and more cost effective manufacture since they are available separately from the whole ventilation system or, with no ventilation system at all.

There are two main steps for calibrating a main-stream capnograph, both of which find common use in NDIR gas sensing systems.

The first step takes advantage of an already calibrated environmental chamber, with gas driven inside at known concentrations while the temperature is varied. NDIR spectrometers (here, main-stream capnographs) are placed in the chamber, with calibration functions derived from these readings as the concentration and temperature are fluctuated.

In the second step, zeroing of the pre-calibrated capnograph can take place in a hospital (in an open and non-crowded space) or simply outside, where the concentration of CO2 from breath is close to atmospheric.

Sensing the way ahead

To achieve optimised capnography, a number of prerequisites are required of the infrared CO2 detector, not least a low-profile package, instant start-up capability and low power consumption. However, fast data readout speed is arguably the most important factor.

The typical requirement for capnography systems is that the detector takes a reading at ~20-40Hz. Most pyroelectric detectors offer their optimum efficiency at around 2-10 Hz, making them too slow for high-quality capnography devices. However, using proprietary thin-film technology in the manufacturing process results in sensors with detection speeds more than five times quicker than competing technologies. Sensors manufactured this way also start up and stabilise extremely quickly, and are very stable in environments with fluctuating temperatures, such as hospitals.

Popular proprietary solutions include dual-channel analogue IR detectors, where the second channel serves as a gas reference, and low-profile surface mount digital sensors. The latter are increasingly in demand due to the miniaturisation trend in main-stream capnographs and their readiness for high volume manufacturing.

Reflecting the rising demand, Pyreos recently reported five times revenue growth in medically approved breath analysis applications for critical care settings, and growth of several multiples in breath analysis sensors for handheld battery-powered consumer health products.

Bridging the capnography gap

When it comes to regions like Europe, demand for core gas sensors used in capnography systems has grown by several multiples in recent years. However, this is creating a worrying ‘capnography gap’ among low-income countries.

To help alleviate the situation, Pyreos is working towards the introduction of a world-first development that could help to radically shift the landscape for ICU capability in low-income countries. The company is looking to develop a significantly more affordable capnography kit based on the use of proprietary SMD (Surface Mount Digital) gas detectors. As SMD sensors cost around three times less than analogue equivalents, the move represents an inexpensive opportunity to prevent unnecessary deaths. In addition, these integrated solutions save on BOM cost and board space as they include power management, filtering, amplification and a DAC.

Clearly, capnography is a fast-moving market that relies on its underlying technologies, not least infrared CO2 detectors, to provide accurate respiratory disease diagnosis, the world over.