Current-sensing dynamics in automotive solenoids

During my first visit to the US, my brother and I drove from New York City to Columbus, Ohio. Although the 650-KM (400-mile) journey was long, our car’s automatic transmission and cruise control made the trip more comfortable.

By Sandeep Tallada, Automotive Systems Engineer, Texas Instruments

The effectiveness of an automatic transmission and cruise control relies on the precise control of proportional solenoids and motors, which is made possible with accurate current measurement.

Proportional solenoids convert electrical signals into a proportional mechanical force, which allows variance in armature position and force relative to the level of current. Proportional solenoids are used in automotive applications such as automatic transmissions, fuel injection systems, pistons and valves to accurately control position or flow. Controlling proportional solenoids precisely is highly dependent on the accuracy of the position estimation over the automotive temperature range. In general, measurement is used to provide position for proportional solenoids.

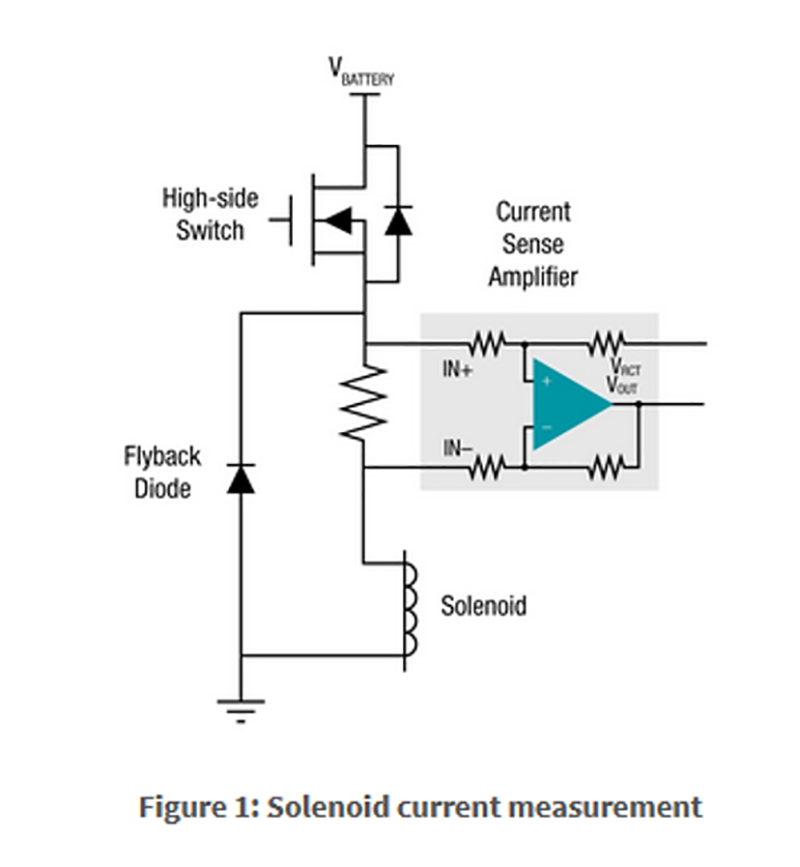

As shown in Figure 1, a shunt resistor is inserted in between the switch and the solenoid. The low-ohmic shunt is inserted in such a way to create a low resistance path as well as safely measure and accommodate recirculation current flows. An amplifier in a differential configuration or current sense amplifier is connected to the shunt to measure the current.

A pulse width modulation (PWM) signal operates the high-side switch. When the PWM is high, the battery connects to the solenoid and current flows. When the PWM is low, the battery disconnects from the solenoid and recirculation current flows through the flyback diode.

The control of the PWM frequency and duty-cycle percentage determines the resulting average current in the solenoid, which in turn controls the force applied to the actuator.

Sensing accuracy

Nominal current ranges for solenoids vary from device to device. Because of differing current range needs, current sense amplifier selection for these types of systems is critical as the necessary precise movement of the entire solenoid system depends on the accuracy of the current measurement.

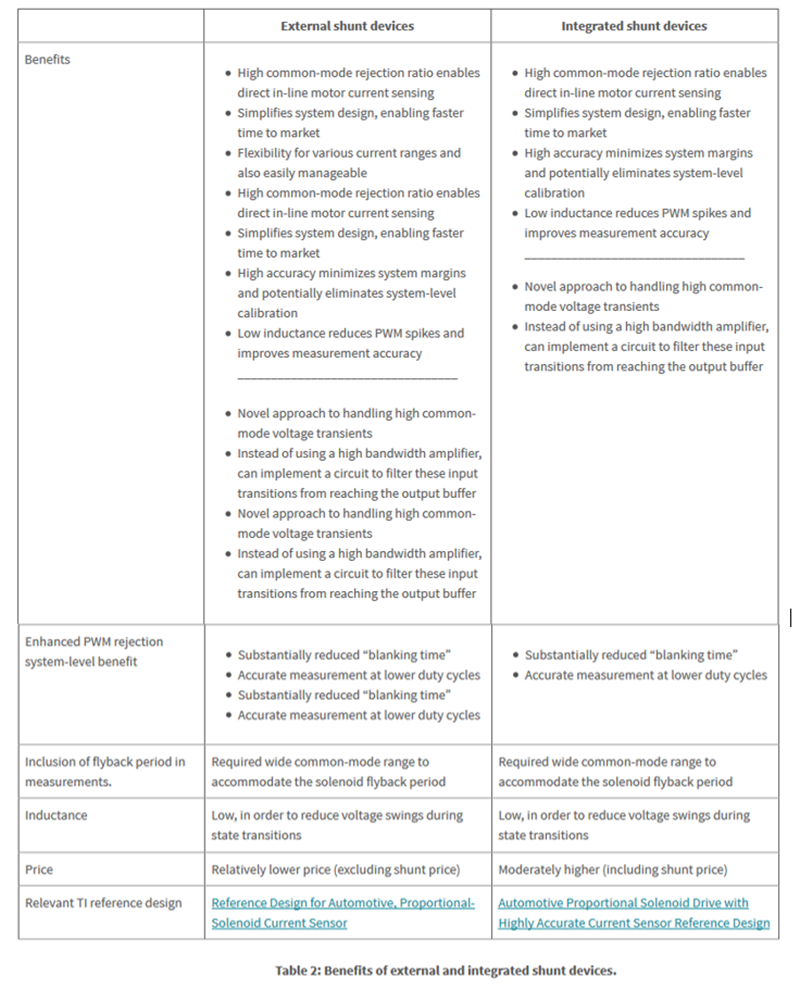

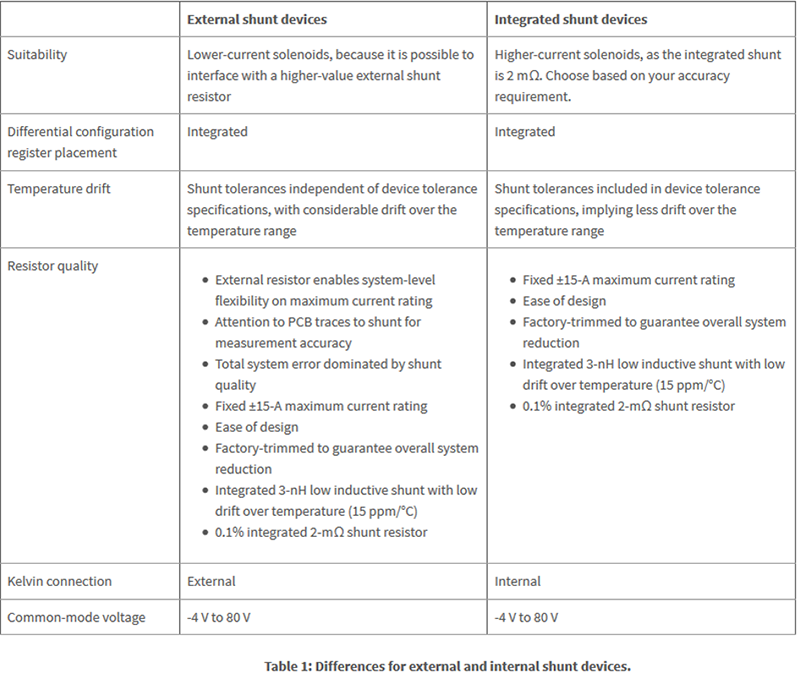

Solenoid current sensors can be designed with external shunts or integrated shunt devices depending on the accuracy requirement. Each has their own advantages. Tables 1 and 2 summarise the differences and benefits of these two architectures.

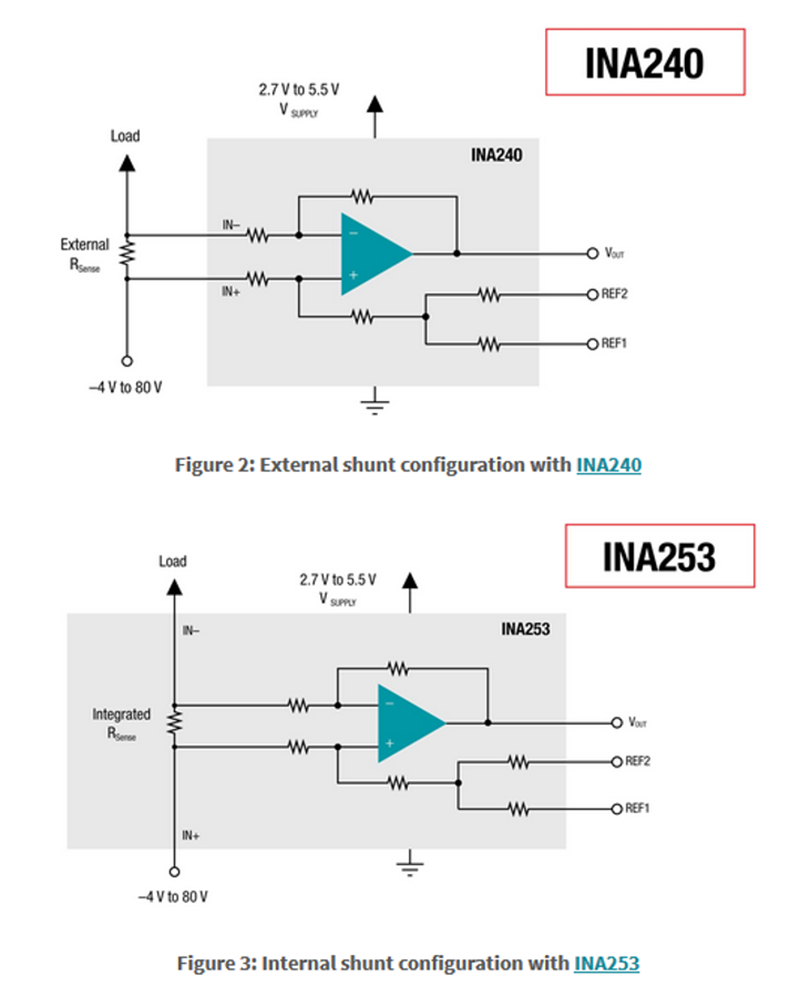

Figures 2 and 3 shows the configurations of shunt for external and internal configurations. In Figure 2 shunt is external to the device (INA240-Q1) and in Figure 3 shunt is internal to the device (INA253-Q1).

Maintaining solenoid current sensing accuracy

The impedance of a solenoid comprises inductive and series resistive components. The series resistance of the coil (typically copper) has a high-temperature drift of 4,000 ppm/°C. This high drift value may correspond to a 40% accuracy reduction in solenoid motion control over a 100°C range.

Accuracy at lower current ranges is essential over the entire temperature range mainly because lower currents are noise prone and there is a more chance for the solenoid position inaccuracies. Smooth operation of hydraulic systems requires a minimum 2-mA resolution. Variations in this resolution cause solenoid position inaccuracies.

TI has two devices designed for solenoid current sensing applications:

- The INA240-Q1 enhances PWM rejection and has significantly lower offset and gain drifts over the temperature range, minimising error at a 2-mA resolution.

- The INA253-Q1 is a low inductive 3-nH 2-mΩ integrated shunt with a drift at 15 ppm/°C. Placing the INA253-Q1 in series with the solenoid, the drift accuracy can decrease overall end-equipment system errors from 40% to 0.15%.

These devices have increased the effectiveness of our powertrain, motor-control circuits and automotive battery systems.

Conclusion

Automotive solenoids need higher accuracies to compensate for wider temperature ranges and increased drift as the temperature increases. Our current-shunt monitors enable accurate readings across the entirety of automotive temperature ranges.