The case for modules stacks up in the electric vehicle age

A modular approach to a 48V power architecture can be the solution to automotive electrification challenges

Manufacturers of cars, trucks, buses and motorcycles are rapidly electrifying their vehicles to increase the fuel efficiency of internal combustion engines and reduce CO2 emissions. There are many electrification choices, but most manufacturers are opting for a 48V mild-hybrid system rather than a full hybrid powertrain. In the mild-hybrid system, a 48V battery is added alongside the traditional 12V battery.

This increases power capacity by a factor of four, which can be used for heavier loads, such as the air conditioner and catalytic converter at start-up. To increase vehicle performance, the 48V system can power a hybrid motor that is used for faster, smoother acceleration while saving on fuel. The additional power can also support steering, braking and suspension systems, plus new safety, entertainment and comfort features.

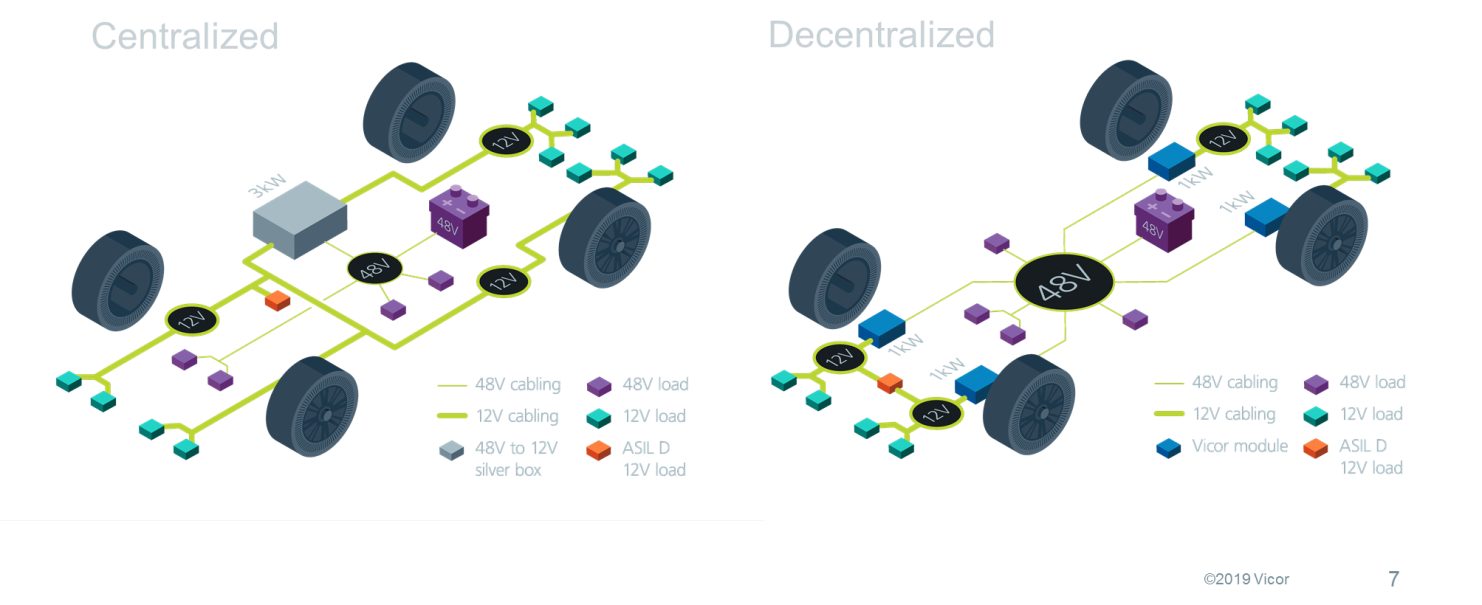

Figure 1: Traditional 12V centralised architecture (left) and 48V decentralised architecture (right).

Introducing a 48V mild hybrid system has tremendous upside once designed-in. Overcoming the hesitancy to modify the long-standing 12V power delivery network (PDN) may be the biggest challenge. Changes in power delivery often require new technologies that need extensive testing and may require new suppliers that can deliver on the automotive industry’s high safety and quality standards.

But the advantages far outweigh the conversion cost as the data centre industry is discovering as it moves to a 48V PDN. For the automotive industry a 48V mild hybrid system provides a way to rapidly introduce new vehicles with lower emissions, longer range and higher gas mileage. It also delivers new and exciting design options for higher performance and features while still reducing CO2 emissions.

Maximising PDN

Adding a 48V battery to power the heavier powertrain and chassis-system loads provides options to engineers. Now there is a choice of adding systems that can deal directly with a 48V input, or to retain legacy 12V electromechanical loads such as pumps, fans and motors and instead convert the 48V to 12V via a regulated DC/DC converter. In order to manage change and risk, existing mild-hybrid power delivery systems are slowly adding 48V loads but still use a large centralised multi-kW 48V-to-12V converter that feeds 12V around the vehicle to the 12V loads. However, this centralised architecture does not take the full advantage of a 48V PDN, nor does it utilise the benefits of available advanced converter topologies, control systems and packaging.

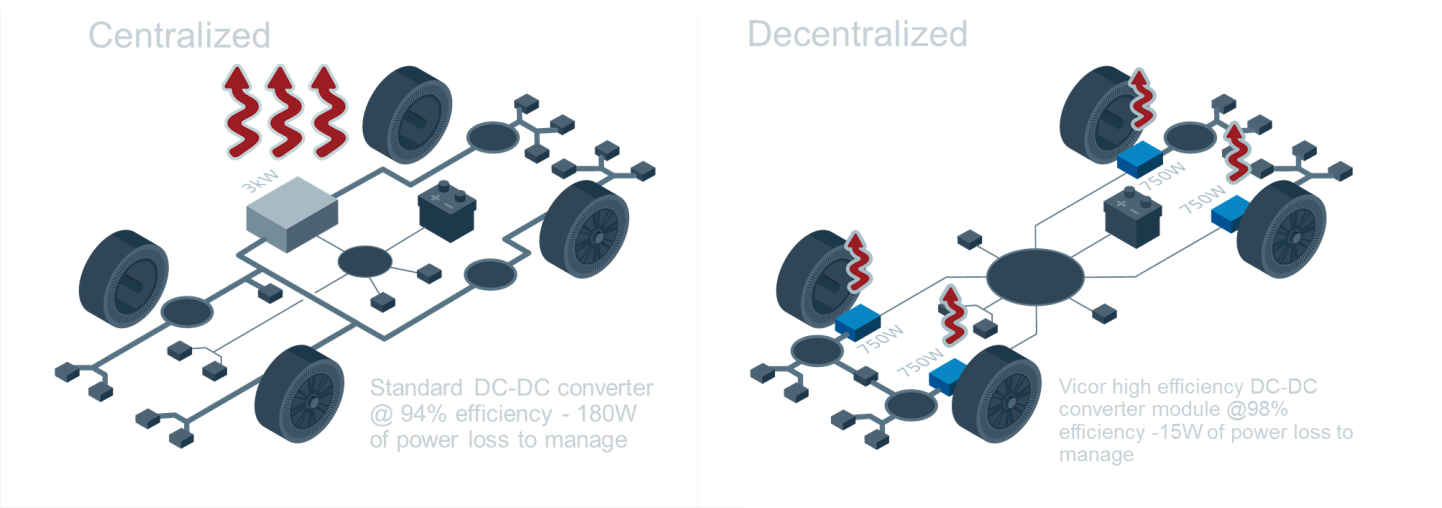

Figure 2: A standard DC/DC converter (left) is 94% efficient. A Vicor DC/DC converter (right) is 98% efficient.

Figure 2: A standard DC/DC converter (left) is 94% efficient. A Vicor DC/DC converter (right) is 98% efficient.

The vast majority of these centralised DC/DC converters are bulky and heavy, because they use older low-frequency pulse width modulation (PWM) switching topologies. They also represent a single point of failure for many critical powertrain systems.

A different architecture to consider is decentralised power delivery with modular power components. This power delivery architecture uses smaller, lower-power 48 to 12V converters, distributed throughout the vehicle close to the 12V loads. The simple power equations P = V * I and PLOSS = I2R explain why 48V is more efficient than distributing 12V.

For a given power level, the current is four times lower at 48V than in a 12V system and has 16 times lower losses ( I2R). At ¼ of the current, the cables and connectors can be smaller, lower weight and cheaper. The decentralised power architecture also has significant thermal management and power system redundancy benefits (Figure 2). It is another way of spreading kW of power around the vehicle without the weight, thermal concerns and volume of a traditional DC/DC converter.

The scalable module

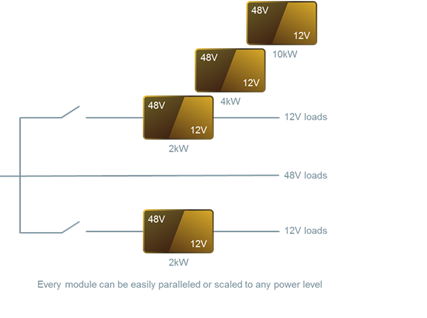

A modular approach to a decentralised power delivery (Figure 3) is highly scalable.

Figure 3: A modular approach to a hybrid electric vehicle.

Figure 3: A modular approach to a hybrid electric vehicle.

The 48V output from the battery is distributed to the various high-power loads in the vehicle, maximising the benefits of lower current (4x) and lower losses (16x) resulting in a physically smaller and lower weight PDN. Depending on a load power analysis of the various distributed loads, one module can be designed and qualified for the right power granularity and scale the power level of the system upwards, when used in parallel arrays.

In this example, a 2kW module is shown. The granularity and scalability are system-dependent. By using distributed modules instead of a large centralised DC/DC converter, N+1 redundancy is also possible at a much lower cost. This approach is also advantageous if load power changes during the vehicle development phase. Instead of implementing changes to a full ground-up custom power supply, engineers can either add or eliminate modules. Another design advantage is reduced development time as the module is already approved and qualified.

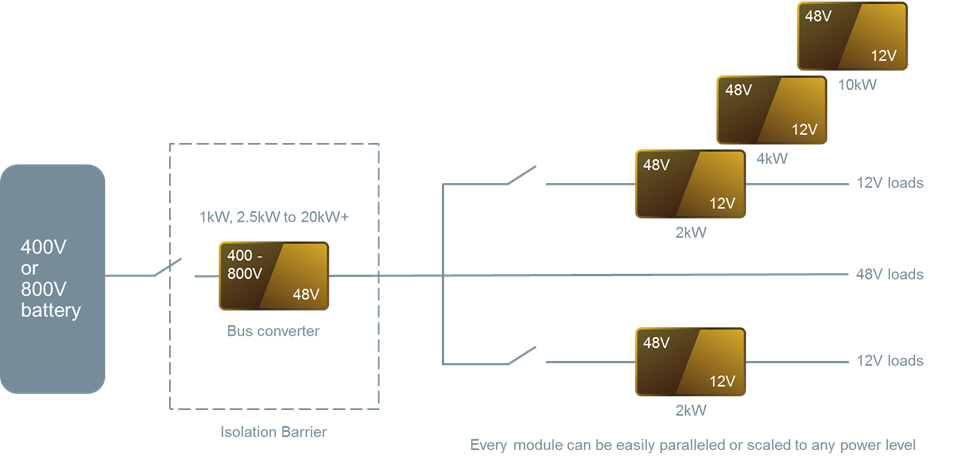

There may also be instances requiring a decentralised modular 48V architecture in higher voltage battery systems. Figure 6 shows a modular approach in a fully electric vehicle.

Figure 4: A modular approach to a decentralised 48V architecture in a fully electric vehicle.

In the case of pure electric vehicles or high performance hybrid cars, high voltage batteries are used due to the high power demands of the powertrain and chassis systems. A 48V SELV PDN still has significant benefits for OEMs, but now the power system designer has an additional challenge of a high-power 800V or 400V to 48V conversion.

This high power DC/DC converter also requires isolation but not regulation. By using regulated PoL converters, the high power upstream converter can use a fixed ratio topology. This is extremely beneficial due to the wide input to output voltage range of 16:1 or 8:1 for 800/48 and 400/48, respectively.

Using a regulated converter over this range is very inefficient and presents a large thermal management problem. OEMs often locate this efficient step down solution inside the battery pack and in some cases are able to eliminate the battery. Vicor’s fixed ratio, high voltage conversion products deliver rapid current delivery at fast slew rates, enabling automotive OEMs to lose the 12 to 14kg of unnecessary 48V battery weight.

It would be very difficult and costly to decentralise this high voltage isolated converter due to safety requirements in distributing the 400V or 800V. However, a high power centralised fixed ratio converter can be designed utilising power modules instead of a large silver box DC/DC converter.

Power modules of the right level of granularity and scalability can be developed and then easily paralleled for a range of vehicles with differing powertrain and chassis electrification requirements. Vicor fixed ratio bus converters (BCM) are also bi-directional, which supports various energy regeneration scemes. Due to the sine amplitude converter (SAC) high frequency, soft switching topology, BCMs achieve efficiencies over 98%. They also feature power densities of 2.6kW/in3, which significantly reduces the size of the centralised high voltage converter.

A modular approach to automotive power systems, simplifies complex power delivery challenges, increasing performance, productivity and time to market.

About the authors

Patrick Wadden is Global Vice President of Automotive Business and Nicolas Richard is Director of Automotive Business, Vicor