Hyperactivity accelerates hyperloop potential

Gridlock on roads, congestion and delays at airports have all conspired to make travel a chore. Imagine if you could be whisked to your destination in minutes rather than hours. This is the hyperloop vision, writes Caroline Hayes.

Entrepreneur Elon Musk proposed a hyperloop transportation system in a whitepaper in 2013. His vision of pods whizzing through a network of tunnels, travelling at hundreds of miles an hour captured minds and the hearts of engineers. Teams of researchers, engineers and academics dreamed of the 620km (385 mile) commute between Los Angeles and San Francisco taking just 35 minutes.

The Tesla Chairman and CEO envisaged a network of tubes within which levitated pods travelled at close to the speed of sound. Nodes along the networks would be similar to airport hubs, to allow a criss-crossing of continents in a fraction of the time we expect to take today.

The pods would be silent and energy efficient, using magnetic levitation to propel the pods through the hyperloop tubes at these speeds. Ironically, Musk’s futuristic concept was echoing an 18th century engineer’s idea. George Medhurst patented the Aeolian engine in 1799, which used air to drive close fitting, piston-like, four wheeled carriages along underground tunnels. Medhurst’s proposal was for carriages travelling at 60mph (96.5kph). He was ahead of his time - in 1829, Robert Stephenson’s Rocket locomotive pulled trains along the London to Birmingham railway at 28mph (45kph).

Isambard Kingdom Brunel also suggested a pneumatic railway system. His Atmospheric Railway, from Exeter to Newton Abbot, in Devon, reached speeds of 70mph (112.5kph). Although near silent in operation, it proved to be more expensive than conventional steam power and was discontinued.

Travel details

Now, in the 21st century, super high speed travel is within sight once more. Musk wrote that the hyperloop pods will travel in evacuated tubes above the ground, at an average speed of 600mph (970kph), with a top speed of 760mph (1,200kph) per hour. The tube would diminish the drag force of atmospheric air. The low pressure would reduce the air resistance for the capsules to be propelled by linear induction motors through the tubes at these high speeds with low energy consumption. Magnetic levitation is resurrected, this time to create a cushion of air for the capsules to float, reducing friction.

Musk’s SpaceX has a hyperloop system at its California headquarters. The one mile (1.6km) long section played host to the inaugural SpaceX Hyperloop pod competition this year, in which university teams were invited to design and test self-propelling pods in a speed challenge.

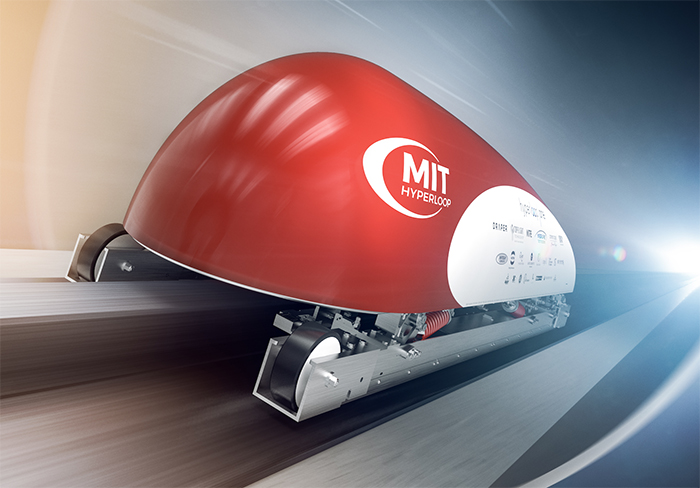

This year, the team from Massachusetts Institute of Technology (MIT) won the Safety & Reliability award, and were awarded third place for design and construction.

Their pod has an aluminium frame and tubular shell of woven carbon fibre and polycarbonate sheets. It measures 2.5m (eight foot) in length and one metre (39”) wide. It uses a passive magnetic levitation system consisting of two arrays of 20 neodymium magnets. It maintained a 15mm levitation gap height after lift-off. Before and after high speed runs, a drive system clamps to the rail for low speed travel. A non-contact braking system uses an array of over 400 magnets at 2.4G maximum. Within the pod, there are 24 and 36V Li-ion batteries and over 30 sensors for monitoring and control of the pod.

Above: Hyperloop One’s XP-1 pod, being prepared for test

The MIT team, captained by Max Opgernoord, a graduate in the Department of Aeronautics and Astronautics, achieved speeds of 246mph (396kph) without passengers or cargo.

To realise an efficient, reliable hyperloop system, there are some substantial technical challenges. The first is to maintain a near-vacuum environment inside a tube that can run for hundreds of kilometres. Maintaining magnetic levitation, and smooth braking while travelling at the target speed of 700mph (1,112km) and 2.5G of acceleration is another.

Testing times

Much of the research and development is focused on magnetic levitation. A Los Angeles-based company, Hyperloop One, is leading the field. The company was created in June 2014, as Hyperloop Technologies. It has been designing and testing hyperloop components at the Los Angeles Innovation Campus, and began constructing a hyperloop test track in the Nevada desert in September 2016. At CWIEME Berlin, Alex Jedinger, Electromagnetic Design Engineer at Hyperloop One, described DevLoop, the company’s full scale test system.

“To develop a complex system like hyperloop, it is important to test components at full scale as soon as possible,” said Jedinger. “We did propulsion open air tests in May 2016. We tested not just the electric motor, but also the power electronics, the Variable Frequency Drives (VFDs) and connection to the grid, the first implementation of the pod and our control systems.

“DevLoop will be our proof of technology - a crucial testbed - which lets us answer questions. It will give us the competitive advantage of running hundreds of tests and really understanding technology and behaviour of the full system,” he said. The results from these tests will be channelled into the first few hyperloop production systems.

This was the company’s first large project and was achieved in around nine months. Jedinger explained that development, manufacture, installation and testing of the first custom hyperloop propulsion motor went “from sketches on a white board, and a bare patch of desert land, to a fully fledge test,” in less than ten months. The high speed test reached 216kph (134mph) within 2.5 seconds, “that’s more than 2.5G of acceleration,” confirmed Jedinger.

Above: The MIT team’s pod was recognised for safety and reliability in the SpaceX challenge

After the propulsion open air tests, the full system, or DevLoop, is being tested. This encompasses the vacuum and propulsion, and the levitation and guidance systems. The Hyperloop One pod, called XP-1, is a carbon fibre construction, with an aluminium aeroshell over the levitating chassis.

The motor is over 100m long, which is long, even for the first test, conceded Jedinger. It had to be this long, as it was not possible to just connect one VFD to the model. The motor was split into sections and Hyperloop One developed custom switches that change the connection between the VFD and the motor. Once the pod moves from one segment to the next, the early segment is switched off and the new segment is switched on. In this way, the same VFD can be used to power a much longer part of the motor, powering certain sections simultaneously.

The DevLoop test this summer may have only lasted 5.3 seconds but the XP-1 pod reached a top speed of 70mph (112kph), with acceleration of 2G. The company is positive that by lengthening the motor, the pod will travel faster to realise speeds of 250mph (400km) in the next test phase.

Levitation technology

The two most popular magnetic levitation technologies are Electromagnetic Suspension (EMS) and Electro Dynamic Suspension (EDS). For EMS, a magnetic flux flow from the electro magnet to the ferro magnetic material (steel) creates an attractor force in the air gap that wants to pull these two pieces together. This force can be used to create a lift force. “This provides very high force densities,” said Jedinger, “and it will provide lift force at any given speed.” Using EMS, there will always be sufficient lift force for the levitation system, regardless of whether the pod is at full speed.

The system is, however, inherently unstable, said Jedinger, and requires active control at all times. This means it is necessary to have an array of sensors and an active control system that is safety critical in operation. A current example of EMS is the German TransRapid monorail train system.

For EDS magnetic levitation, a permanent magnet moves relative to a conductive surface. The change in magnetic flux of the surface will reduce the voltage and this will drive eddy current that creates another magnetic field that can counteract the original magnetic field. Each repels each other and this can be used as magnetic lift force.

Above: Hyperloop One’s DevLoop test system in the Nevada desert

Jedinger said: “This system does not require any power and so is therefore inherently stable, and also safe.” The drawback is that the technology relies on the relationship between the magnet and the conductor; the magnet moves relative to the conductor. If the pod is at zero speed, there will be no motion. The levitation system relies on threshold speed being reached to provide enough lift force to levitate the entire vehicle.

The SCMagLev (Super Conducting Magnetic Levitation) railway system, developed by the Japanese railway company, JR Central, is being constructing to link Tokyo and Nagoya by 2027, and Osaka by 2045. SCMagLev uses EDS. Super conducting coils on the train create very high flux densities which interact with low flux coils on the track. Jedinger explained that the system is complex and expensive: “It requires cryogenic cooling for the super conducting magnets on the train, and on the track there is an array of different coils for levitation, guidance, propulsion and also for power transfer to the train.”

Hyperloop One bases its technology on EDS for its magnetic levitation. DevLoop uses passive EDS. Hyperloop One uses a permanent magnet moving across an aluminium conductor, creating currents. Eddy currents move along the conductor when the permanent magnet moves. The magnetic flux interacts between the magnet and conductor to create a force.

Although building DevLoop was relatively quick, the end goal of a network of hyperloop tunnels and pods is still some way in the future. The appeal of fast travel, without burning fossil fuels may accelerate some of the projects that are planned to cross state and national borders. Philippa Oldham, head of Transport and Manufacturing at the Institution of Mechanical Engineers believes the construction will be problematic: “Building a sophisticated, evacuated tube system that is elevated on columns and aligned to a standard suitable for 700mph operation will definitely be a challenge,” she warned. She cited track alignment over long distances as one problem. “In the UK, we would not be able to use any existing transport corridors at these speeds due to their lateral curvature,” she noted. In addition, she said, the safety systems would be critical, considering the compression within the hyperloop tunnel and the journey speeds.