How SiCs enable breakthroughs at system level

Progressive system-level design must be adopted, urges Guy Moxey, Wolfspeed, in order to capitalise on the advantages that silicon carbide (SiC) devices provide for power design

It is now well understood that any SiC power device will effectively outperform its silicon (Si) counterpart. Higher voltage blocking capability, faster switching speed, lower on-state loss, and higher thermal conductivity mean that SiC MOSFETs have significantly less switching loss than silicon MOSFETs or IGBTs. SiC diodes have virtually no reverse recovery loss, and both SiC devices conduct significantly more current per unit die area than silicon devices. However, individual SiC devices are not power conversion circuits, so progressive system-level design must be adopted in order to capitalise on the advantages that these power devices provide.

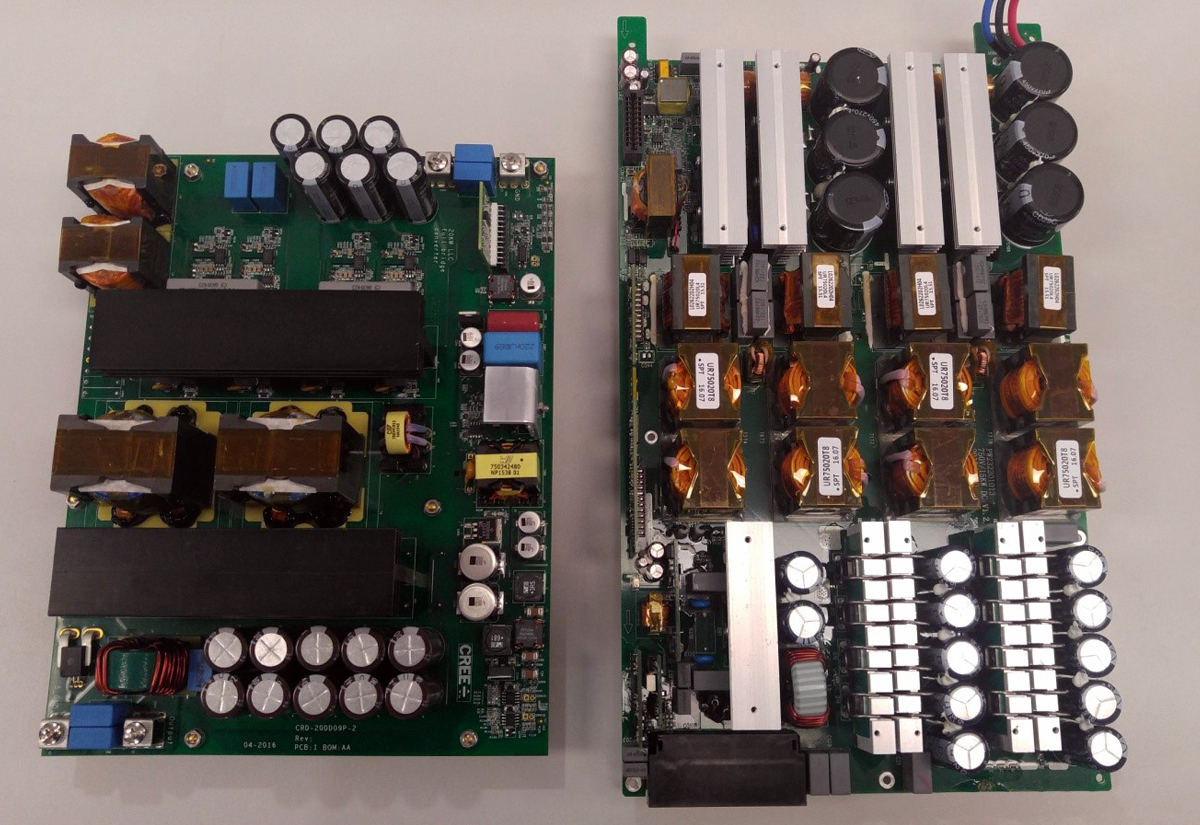

Figure 1: A 20kW WolfspeedSiC DC/DC converter (left) and a 15kW silicon DC/DC converter (right)

Figure 1: A 20kW WolfspeedSiC DC/DC converter (left) and a 15kW silicon DC/DC converter (right)

To maintain the proliferation of new applications and power conversion systems, the industry needs more efficient, more reliable, and lower-cost power system electronics For many years it has relied upon silicon carbide as the only mature, broadly-accepted wide bandgap, semiconductor material.

SiC power devices are used to efficiently convert energy from solar panels into utility grid standard power, and to convert utility power into useful DC and AC power for computers, energy storage systems, digital communications systems, electric motors, battery chargers, and a host of other applications. For example, hybrid electric vehicles (HEVs), plug-in hybrid electric vehicles (PHEVs), and battery electric vehicles (BEVs) all contain several critical systems that benefit from using SiC power devices to enhance both the energy efficiency and performance of EVs, and enable early adopters to achieve a significant market advantage.

Realising potential

SiC devices have provided breakthrough component-level solutions for advanced power electronics sub-systems that are fundamental to any power conversion circuit. The key to moving beyond this, is to effectively harness and use these differentiating devices in practical, real-life power systems.

The demand for vehicle electrification continues to increase and manufacturers seek the latest power electronic technology to improve overall performance, increase efficiency, and reduce cost, weight, and complexity. Wolfspeed C3M065100K 1,000V SiC MOSFETs, for example, enable significant design, circuit, and performance improvements in the DC/DC power converters used in EV off-board charging stations. These SiC MOSFETs deliver the industry’s lowest figure of merit and are implemented in two versions, a two-level LLC resonant converter and a two-level phase shifted converter. The former operates at 200 to 400kHz and provides 98.4% peak efficiency with Vo/p from 200 to 500V, and the latter operates at 200 to 400kHz and provides 97.5% peak efficiency with Vo/p from 200 to 700V.

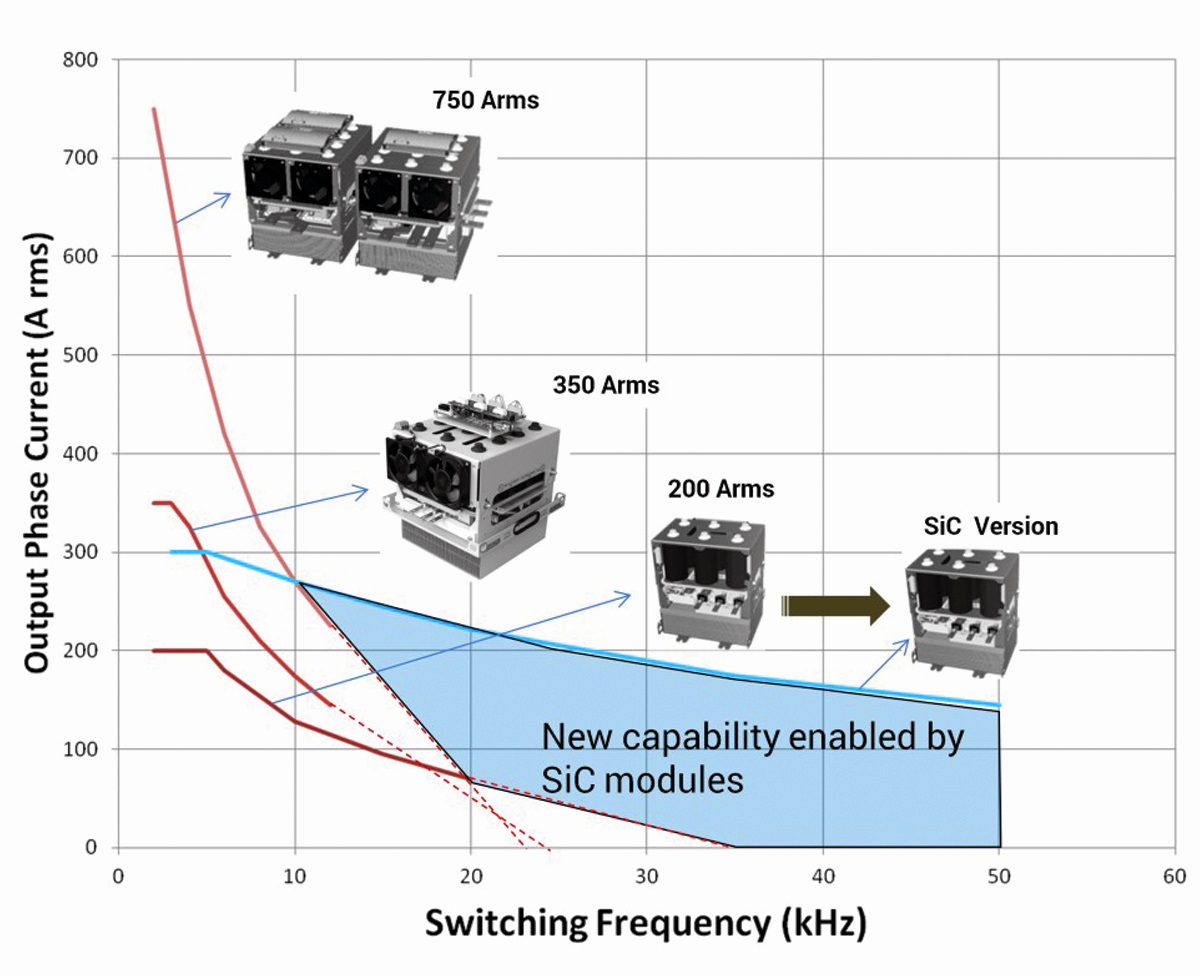

Figure 2: An IGBT stack product family compared with the SiC stack

System-level benchmarking against best-in-class incumbent 650V silicon MOSFETs shows that both of the circuit topologies are modified from three-level silicon designs to two-level SiC designs. The SiC device and circuit topology modifications reduce the number of required devices from 16 silicon to eight SiC MOSFETS, while simultaneously increasing converter efficiency.

Switching to a two-level SiC design also simplifies gate drive design, and - by virtue of operating at higher frequencies - reduces both the size and cost of the magnetic components required. The 1000Vds maximum rating enables the input voltage of both converters to operate to 850V DC.

Efficiency

Figure 1 compares the system-level hardware of an off-the-shelf 15kW silicon DC/DC converter to an off-the-shelf 20kW silicon carbide equivalent containing the company’s MOSFETs. The system-level efficiency of the SiC converter is 98.4% peak, versus 97.5% peak for the silicon converter, for smaller, cooler, and more efficient power converters, using SiC devices.

The company has also demonstrated how its silicon carbide power devices enable breakthrough system-level solutions in commercial, off-the-shelf Si-IGBT stack assemblies based on 62mm, 400A, 1.2kV modules. Typical stacks include system-level components - DC link capacitors, a forced-air-cooled heatsink and blower, and gate drivers with protection logic and sensors.

With a datasheet rating of 140kW (200A rms) output power at a switching frequency of 3kHz, the selected 200A IGBT stack is the smallest of a family of released, commercial products, and represents the type of generic, commercial-module-based power sub-system likely to be found in commercial central solar inverters and motor drives.

In this study, three existing 1200V, 400A IGBT modules were each replaced with the company’s 1200V, 300A CAS300M12BM2 all-SiC modules. The six-channel gate driver board was replaced with three two-channel gate driver boards designed for the SiC modules.

IGBT replacement

The SiC MOSFET modules have built-in SiC Schottky diodes and five distinct performance advantages over the 400A IGBT modules they replaced, namely: lower switching losses, lower conduction losses, negligible diode switching losses, higher breakdown voltage margins, and immunity against cosmic radiation induced failures or single event burnout.

The SiC stack solution was tested as a three-phase inverter. The measured results were compared to the published datasheet values for the IGBT stack. The SiC stack showed significantly lower power dissipation, which can result in the same output power and efficiency at much higher switching frequencies. It can reduce the size, weight, and cost of an overall system and produce more power at the same switching frequency, which can improve power density and watts-per-dollar. It can also allow the system to operate at a lower junction temperature and with higher efficiency with the same operating conditions, effectively boosting reliability.

Figure 2 shows the rated output current of the products versus switching frequency. There is an inverse relationship between the output current and switching frequency. Due to the sharp de-rating of the output current for IGBT stacks, one can see that at 10kHz switching, the 750A-rated IGBT stack, which is three times the physical size of the SiC stack, has the same output current capability.

In combination with the space and weight reductions enabled by the material properties of SiC power devices, they allow power designers to achieve enhanced efficiency and higher power density, in addition to reduced cooling systems, circuit complexity, and thermal management requirements.