Interfaces that touch you back

The industry is working on a multitude of different haptic effects for tomorrow’s touch screens and buttons, writes Sally Ward-Foxton for ES Design magazine.

UIs for electronic devices have come to be dominated by touch screens and capacitive and resistive touch buttons. Although there are many benefits to replacing mechanical buttons and keypads, some say that usability is decreasing, as the user doesn’t get any physical or audible feedback to let them know their touch was registered. Many still miss a physical keypad for smartphones and tablets while, for kitchen appliances, the old-fashioned buttons and knobs could be operated quicker and without looking.

Several different technologies, all with entirely different mechanisms, have been developed to solve this problem by implementing haptic feedback.

Although haptic feedback has been around in gaming controllers for quite some time, creating vibration using a motor attached to a weight inside the controller, much more sophisticated implementations of electromechanical haptics are emerging. Tactical Haptics, formed out of the Haptics and Embedded Mechatronics Lab at the University of Utah, has developed a haptic feedback controller for gaming that it calls Reactive Grip (Figure 1).

.jpg)

Figure 1 - The Reactive Grip controller features sliding contactor bars (the grey bars in the grip). They can be moved up and down separately to create different sensations.

“Reactive Grip can create richer haptic feedback than vibration feedback and can emulate the feeling of inertia, elasticity and damped motion, whereas vibration feedback is mostly limited to representing transient events and textures,” says Dr Will Provancher, CEO, Tactical Haptics. The Reactive Grip controller features sliding contactor bars built into the handle to convey motion and force. Translational motions and forces are made when all the contactor bars move in the same direction. Moving the bars in opposing directions creates the feeling of the handle wrenching in the user’s grasp, perhaps emulating the kick of firing a gun. More complex movements can be conveyed by combinations of these motions - imagine holding a fishing rod with a fish struggling on the line, for example.

“We use linear actuators to move the contactor bars along with standard methods for controlling their motions,” Provancher says. “Game developers simply specify a force vector to our API between the values of -10 and +10 for each bar.”

The initial market being targeted for Tactical Haptics’ technology is gaming, but Provancher says that potential future markets are much broader: “Other applications include training and therapy, for surgical, stroke rehabilitation, maintenance and military applications, as well as teleoperating things like robots in space, hazardous material handling robots or surgical robots,” he adds.

Sense & feedback

Piezo haptics uses a type of polymer material that has piezoelectric properties; the material experiences a mechanical deformation when an electric current is applied. They can also generate electric current when a mechanical force is applied. Applying the right electrical signal to the piezo element can make it effectively vibrate, making it suitable for haptics in electronic buttons.

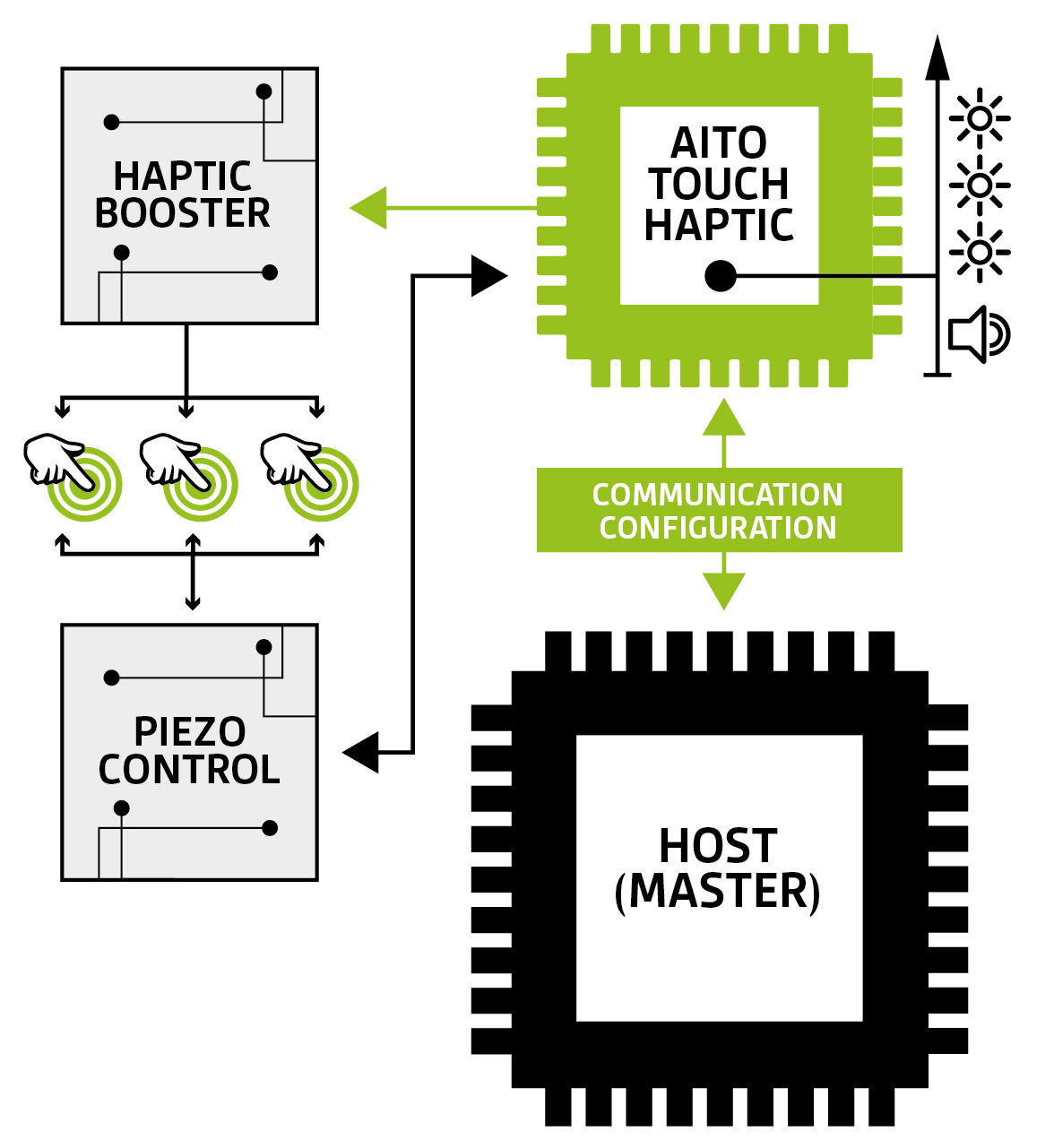

Over and above basic vibrations, a number of companies are working on doing more complex things with piezo, such as Netherlands-based Aito. “Our local, high definition haptic feedback is able to generate a wide range of sensations. We can simulate very precisely the feeling and sound of a mechanical key press, including press and release clicks,” explains Peter Kurstjens, CEO, Aito. “However, the Aito solution actually combines haptic actuation with touch sensing using one single piezo element.”

Figure 2 - Aito’s Software Enhanced Piezo technology uses an industry-standard piezo element controlled by one of the company’s touch controller chips.

Using the same piezo element for both touch sensing and haptic feedback is not straightforward; Aito’s solution uses an industry-standard piezo element, but adds functionality using proprietary software on their haptic control chip (Figure 2). “The software handles the signal processing, reading the input from touch and directly controls the generation of feedback. By coupling the sensing and actuation signals, using a closed control loop, Aito is able to generate a superior haptic experience compared to any existing solution in the market,” adds Kurstjens.

In terms of applications, Aito’s solution is very thin and features very low power consumption, making it suitable for UI control for smartphones and wearables (Figure 3). In the future, Kurstjens expects that haptics will be a bigger part of user interfaces: “We see a trend towards interactive surfaces, in which buttons and controls are invisible to the user until they are needed,” he says. “The controls are seamlessly integrated within the surface material and can be seen and felt by lighting up and giving a local tactile vibration. For instance, in the automotive industry, OEMs are searching for solutions that replace clunky buttons and still provide easy and fast access to most used functions. With Aito’s Smart Piezo, the climate controls or window buttons could be seamlessly integrated within the metal or wooded interior parts.”

Figure 3 - An example of an application for piezo haptics technology in a remote control.

Coulomb’s force, the principle of attraction between positive and negative electrical charges, is the basis for a new type of haptic technology being commercialised by Finnish company, Senseg. The company can make smooth glass surfaces feel like gravel or sandpaper by altering the way the fingers perceive friction from the surface using electrostatics.

In Senseg’s technology, the skin of the fingers is attracted to an oppositely charged electrode, made of a proprietary coating called Tixel. Applying a very low current to the Tixel electrode creates the force, which can be modulated to produce a range of sensations, including textured surfaces and edges, from vibrations (Figure 4). The electrode coating can be applied to transparent or opaque, flat or curved surfaces. The benefits of using Senseg’s electrostatic haptics include completely silent operation, unlike technologies that use vibration as a form of feedback. And as there are no moving parts, it’s quick to respond and operates reliably with low power consumption.

Figure 4 - Senseg’s electrode uses Coulomb’s force to attract the fingertip. The effect can be modulated to make smooth glass feel rough like gravel or sandpaper.

This technique can be used to create haptic feedback for on-screen controls, perhaps in the automotive environment where feeling feedback without looking at the screen is desirable. There is also lots of potential for tablet-based games, with sensations representing different textures, or for accessibility for users who are visually impaired, but it would, of course, depend on manufacturers incorporating the Tixel electrode technology into tablets.

Although the technology is still at an early stage, the company is working with its investor, NXP, who is developing an ASIC chipset for controlling the electrode. The electronics will be deployed next year, but in the mean time, development kits are available, which include an Android based tablet customised with Senseg electronics and software for developing applications.

Feel without touching

Bristol-based startup Ultrahaptics is using ultrasound to provide haptic feedback to a user’s hand. Modulated ultrasound projected towards the hand can deliver different sensations, and software can produce projections that allow the user to feel virtual shapes in mid-air. The user doesn’t have to actually wear or touch anything - just hold their hand above the emitter to get feedback for mid-air gestures or interact with virtual optics (Figure 5).

Figure 5 - Ultrahaptics’ technology lets the user ‘feel’ virtual objects in mid-air.

Ultrahaptics’ latest demo of the technology, debuted at CES, uses an array of standard ultrasound emitters - exactly like those used in vehicle parking sensors (Figure 6). Ultrasound is emitted at 40kHz, which is modulated (turned on and off) at much lower frequencies so that it can be felt, typically 200Hz.

This technology will soon begin to be designed-in to a number of different applications, says Steve Cliffe, CEO, Ultrahaptics: “For automotive applications, physical feedback allows the user to know that their gesture has been recognised by the vehicle without the need to take their eye off the road,” Cliffe says, adding that although automotive design cycles are well-known for being amongst the longest in the industry, automotive gesture systems have been worked on for some time. Ultrahaptics is piggy-backing on the work already completed, to bring ultrasonic haptics to vehicles soon.

Figure 6 - Ultrahaptics’ demo kit uses an array of 256 standard ultrasound transducers. Photo Credit: Kinner Dufort

“The computer industry is very much the same, in that gesture systems such as Intel’s RealSense have already seen significant advancements. Ultrahaptics completes the solutions,” he adds. “However, the control of your home audio system is likely to be the first application to reach the market containing Ultrahaptics technology.”

Another obvious candidate for technology that allows feeling without touching is virtual reality and the world of gaming; as well as seeing and hearing, the user could actively feel their environment. Although it’s a perfect fit, says Cliffe, hardware platforms have to be built and then games built based on that, so reaching the market takes a lot longer than for other types of consumer electronics.

Ultrahaptics will soon be making available an evaluation kit which includes hardware and software. The hardware is an array of 256 ultrasound transducers mounted on a PCB along with a motion sensor (Cliffe says 256 transducers is overkill for most applications, but the evaluation kit is designed for the highest levels of flexibility). Demo software in the kit includes simple switches and dials as well as more complex demos such as bubbles popping on your hand.