Advances in next-gen camera module circuit design

The proliferation of cameras in automobiles to support Advanced Driver Assistance Systems (ADAS) and autonomous vehicles is driving the need for ever-smaller, low-cost cameras, as Dave Lewis, Technical Marketing Manager for FPD-Link ADAS SerDes, Texas Instruments, writes.

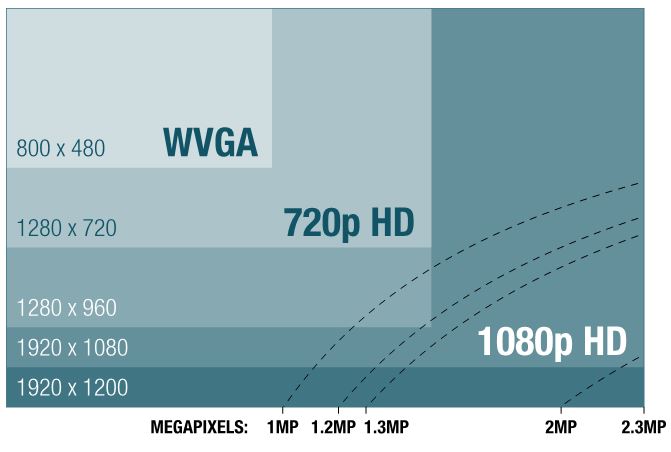

At the same time, automotive imager sensor technology is advancing from simple low-resolution analog to fully digital 1MP (megapixel) and 2MP image sensors (figure 1) with automotive-specific enhancements. The desire for smaller cameras with increased performance and sophistication creates some new design challenges. This article describes novel circuit approaches to overcome these challenges in next generation 2MP automotive camera applications.

Figure 1. Evolution of automotive camera imager resolution.

This is part two in a two-part series. Part 1 entitled 'Sensor Synchronisation and Aggregation in Multi-Camera/RADAR ADAS Applications' described camera ECU deserializer innovations while this article concentrates on camera module circuit design advances.

Wider, faster, farther

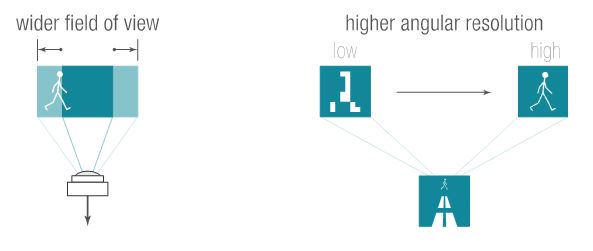

Figure 2. Increased field of view (a) and angular resolution (b).

The trend to higher camera resolution is primarily driven by two requirements: increased field of view and higher angular resolution. The first adds pixels to capture a larger slice of the scene (figure 2a), and the second concentrates more pixels to better resolve and detect distant objects (figure 2b). For increased field of view, higher resolution can record a wider and/or taller picture of the world without sacrificing image quality.

When cameras must identify objects coming towards the vehicle, high angular resolution becomes important. Distant objects appear smaller (they describe a smaller angle) than closer objects. When these distant objects are composed of more pixels, machine vision algorithms can better resolve and detect them farther away and therefore enable the vehicle to react sooner. Recent NCAP legislation is encouraging trends for higher resolution, for example:

- Euro NCAP recommendations call for detection of pedestrians and cyclists. Wider field of view is beneficial to detect these objects at the periphery of the driver’s vision.

- Functions like Automatic Emergency Braking (AEB) necessitate rapid detection of objects at longer distances, driving the need for increased angular resolution.

Of course, multiple smaller camera imagers in parallel can be also employed to increase resolution. Using a single higher resolution camera, however, delivers a smaller, potentially lower cost camera module.

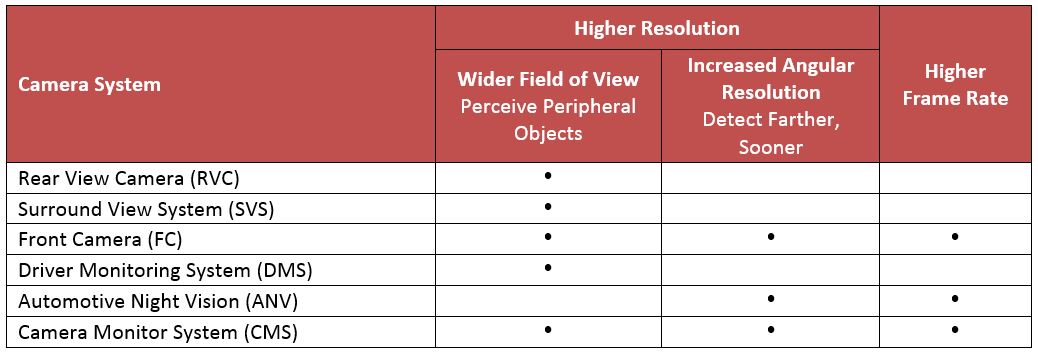

In addition to higher resolution, cameras used at highway driving speeds typically also require higher video frame rates. For example, camera monitoring systems (CMS, often called eMirror), which replace side and rear view mirrors, may require up to 60 frames per second (fps) to provide smooth video to drivers at highway speeds. Table 1 summarises general resolution and frame rate trends for various ADAS camera systems. Both higher resolution and increased frame rates place significant new challenges on camera module and processing design.

Table 1. Trend for higher >1MP resolution and >30 fps frame rate by application.

Next-gen camera design

In addition to higher resolution and performance, automotive cameras must remain small and reliable as well as offer excellent performance under challenging lighting conditions. Typical camera design goals include:

- Small camera module size (≤20x20mm)

- High performance especially low light sensitivity

- Low power and heat for minimal thermal noise

- Affordable for broad deployment

- Increased resolution and frame rate

- Compliant to stringent automotive EMC requirements

- Data protection and rich diagnostics for system functional safety

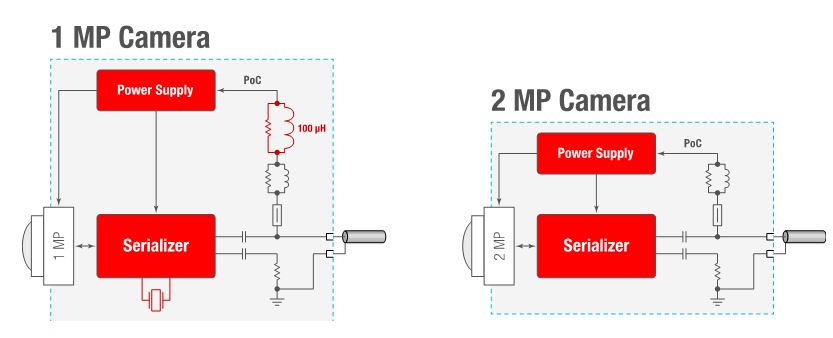

Figure 3. Designs for (a) traditional 1MP camera and (b) new 2MP camera.

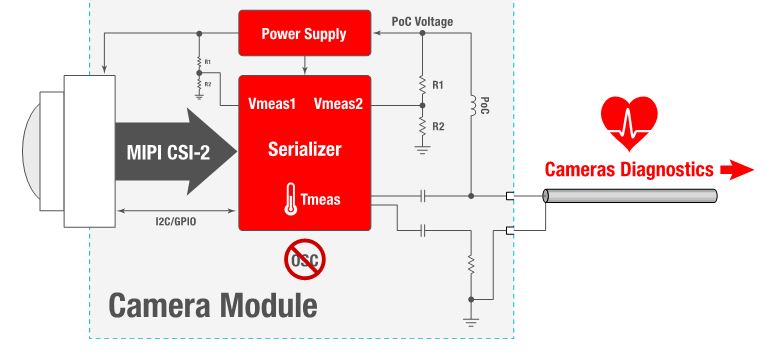

Cameras are commonly connected to video processing Electronic Control Units (ECUs) via a single coax cable using serializer/deserializer (SerDes) devices (figure 3a). The coax cable carries everything needed to support the camera: raw uncompressed video data, a low-latency bidirectional control channel, and power through one small connector. This approach is often termed Power-over-Coax (PoC), and it simplifies camera interconnect while minimising camera footprint.

A new breed of SerDes devices is now extending performance from 1MP to 2+MP while further reducing camera size (figure 2b). The 2MP serializer is clocked over the link by the ECU via back channel communication, eliminating the need for a local oscillator. This provides two important benefits: (1) removal of the oscillator saves space as well as improves reliability and (2), video from all cameras is synchronised to a central clock, simplifying video processing. In addition, faster backchannel communication channel over the link allows the elimination (depending on imager supply noise) of the large 100μH PoC filter, saving approximately 50mm2 of PCB area. The result is a higher performance yet smaller camera.

A better interface

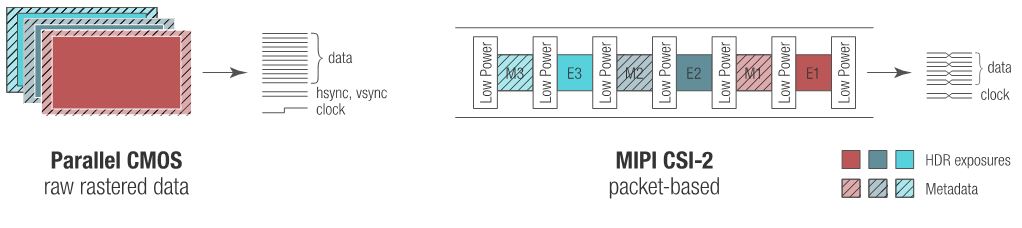

Traditional serializers receive imager data over a parallel LVCMOS bus (figure 4a). Parallel LVCMOS buses, however, tend to consume more power and generate more EMI versus differential buses. Separating different types of imager data is also problematic. For example, metadata associated with each frame and exposure must be stuffed into extra video rows and/or columns, forcing the ECU to count bits in order to distinguish video data from non-video information. Furthermore, the entire video transmission path timing is tied to the pixel clock (PCLK) of the imager. This makes it harder to aggregate and process video from cameras of different resolutions and frame rates.

Figure 4. Imager interfaces (a) parallel and (b) MIPI CSI-2.

To solve these issues, automotive applications are adopting the MIPI CSI-2 standard, an imager interface popular in smartphone cameras (figure 4b). CSI-2 is a quasi-serialized differential bus enabling high throughput with low power and EMI. CSI-2 is also packet-based, operating independent to the PCLK pixel clock frequency of the imagers. Packets are transmitted in bursts on the CSI-2 bus at a fixed frequency with low power states filling idle periods. This architecture uncouples imager pixel frequencies from the data transmission path, easing video aggregation and processing from multiple cameras of disparate resolution, frame rate, and format. CSI-2 contain headers that include data content and channel fields to make it easy for processors to distinguish video, exposures, and metadata from multiple cameras without the need to count interleaved bits. Finally, CSI-2 includes additional features such as CRC data protection to enhance system robustness and functional safety. CSI-2 brings a more modern approach to video interfacing and helps enable mixing sensors of various types and speeds in sensor fusion systems.

Functional safety - data protection and diagnostics

Functional safety is a system requirement; therefore individual SerDes devices typically do not generally carry a functional safety ASIL level. A new family of SerDes devices, however, integrates innovative data protection and diagnostic features to support overall system functional safety. These SerDes devices protect data using CRC on both forward and back channels to warn the system if data is corrupted and also check incoming imager data for bit errors, allowing the system to determine where in the signal chain errors originate. If errors do occur, the serializer alerts the ECU and commands are not propagated. This helps prevent misconfiguring the camera module.

Figure 5. Serializer camera module health diagnostics.

The serializer also incorporates rich diagnostics to monitor camera module health (figure 5). These diagnostics include link and clock health checking, temperature and supply voltage monitoring, and a programmable alarm/interrupt mechanism. Camera health factors are continually monitored, and a configurable alarm warns the ECU when any of these variables exceeds programmed limits. This frees the ECU from having to constantly poll camera status. Up to two voltages can be monitored for over- and under-voltage conditions. External voltages are divided down to a nominal value, so even PoC voltages exceeding the chip’s supply voltage can be monitored within the camera. Using these diagnostics, the camera module can be constantly supervised for proper operation and a system warning generated before camera failure occurs. Together with data protection, diagnostics increase camera robustness and reliability, helping to support overall system functional safety.

Conclusion

New higher resolution 2MP, 60 fps cameras with exceptional low-light performance will improve ADAS capabilities and facilitate the transition to autonomous vehicles. The challenge is to increase capability and sophistication while continuing to drive down the size of cameras modules. Innovative SerDes links are bringing new approaches to increase performance and reliability while reducing camera size and circuit complexity.