Taking back the power

PMICs (Power Management Integrated Circuits) ease the power burden and streamlining power design in smart phones and ultra portable PCs. By Dave Blissett, Smart Energy/Home Automation specialist, Ismosys.

Mobile computing of all kinds is booming. The public has a seemingly insatiable demand for a myriad of different smart phones, ultra portable computers and tablets.

The demand for even more functionality squeezed in to smaller and thinner devices has brought about a ‘squeeze’ of a different kind. Power management has become a key factor as users consume and create more content on the move for longer periods between battery charges.

In 2014 1.9bn handsets are forecast to be shipped, meanwhile shipments of ‘ultra-mobiles’ (tablets of all sizes) will for the first time outnumber those of PCs rising to break the 300m mark.

Effective power management is vital for the success of any mobile product. Consumer’s cite poor battery life as the single most annoying feature of their mobile equipment. Modern 4G phones use more battery power for decoding high data rate transmissions. Additionally, consumers now use their phone to talk, text, email and video conference; not forgetting music streaming and GPS location finding functionality. All of these features make the need for effective power management ever more pressing.

Traditional power management has typically meant on-chip control, integrated with the host processor. As power needs have become more complex this approach is no longer feasible in sophisticated designs. The inclusion of multicore processors and all of the subsystems of a modern phone or tablet, such as WiFi, Bluetooth, high resolution screens and megapixel cameras, requires a new generation of dedicated PMICs which can supply and control multiple outputs as well as the voltage scaling and sequencing demanded by multicore mobile designs.

A PMIC can in some cases generate up to 30 different power lines within one phone or tablet to feed the different communications, multimedia and processing blocks on a modern battery powered mobile device. By using a dedicated PMIC, designers can gain greater efficiency than with an on-chip system, by using many individual low voltage supplies.

One significant advantage when using PMICs is that they allow designers to use a ‘platform’ approach to designs, allowing easy customisation and late changes to a design. Needless to say, the market is highly competitive for any designer working in the field of mobile products. OEMs are under pressure to release new models typically every 6-9 months, and consumers demand new features as manufacturers aim to keep up with the competition.

Increasingly modern smartphones and tablets use multicore processors. This approach allows for a significant power advantage by pairing a simple processing core alongside a more complex core allowing the device to use processing resources efficiently.

For example, when playing a graphically sophisticated game the GPU and the display will draw most power; the CPU will be able to reduce power and speed giving the best overall result.

Despite this complexity there is a significant advantage to using multicore devices, allowing simple tasks access to their own core while delegating complex tasks to more powerful processing cores.

Sequencing

Each of these application processors need to be individually sequenced correctly. Using a PMIC can greatly simplify this task by controlling blocks within a system; individually powering them up and down into sleep mode and correctly sequencing their operation.

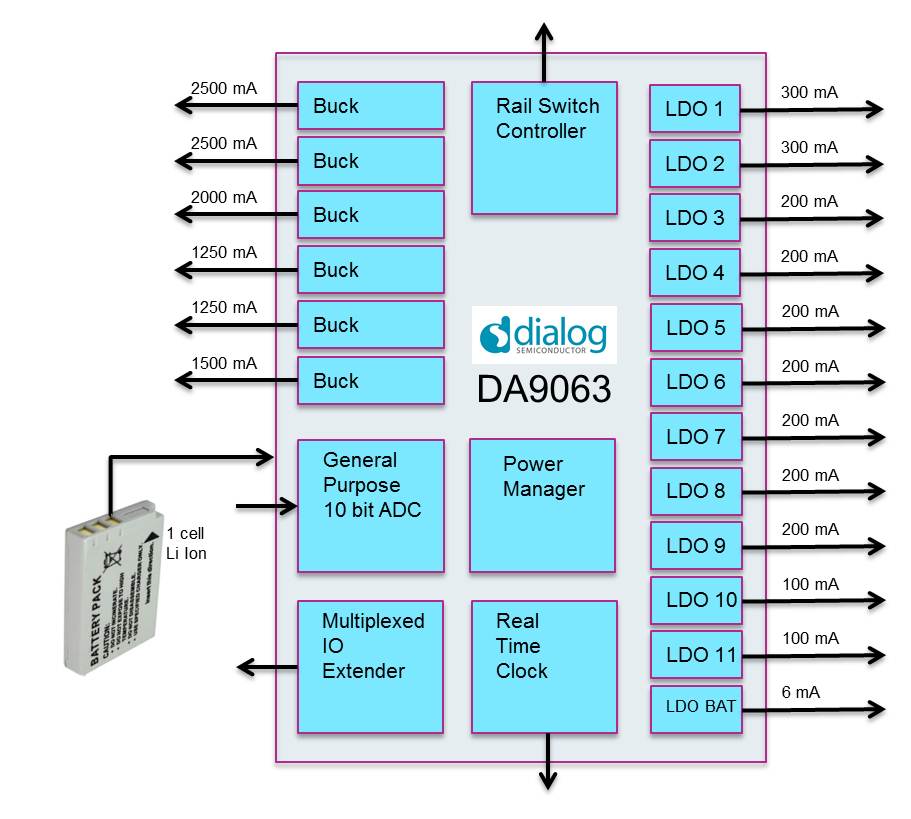

A good example of a flagship PMIC with multicore support is Dialog Semiconductor’s DA9063. This leading edge device is aimed squarely at dual and quad core processor designs.

The DA9063 features six buck regulators operating at 3MHz and is able to deliver up to a total of 12A from its six DC/DC converters. The device can simultaneously power the processor (the core at up to 5A plus other processor supplies) and external memories, together with wireless communications, GPS and other peripheral blocks.

The DC/DC converters can be paralleled to provide 3 and 5A rails, meaning the PMIC is scalable and can be adapted for different requirements in smart phones, tablets and other embedded applications.

Also included are 11 LDO’s, 16 GPIO’s and two rail switches. Any start-up sequence, output voltage and DVC ramps can be programmed allowing designers to minimise energy consumption. The buck converter’s 3MHz switching frequency enables inductors to be just 1mm high while maintaining the high Peak current.

The DA9063 can manage energy flow from multiple inputs

The device features a switched mode DC input and USB compatible charger, full power path management as well as multiple sleep modes. Using the DA9063 designs can be created with exceptional energy efficiency based around many different processors from vendors such as Freescale, Marvell, Renesas and Samsung.

The DA9063 interfaces directly to a Li-ion/polymer battery pack and supports precise current/voltage charging as well as pre-charge and USB modes without processor interaction. During charging, die temperature is thermally regulated which enables higher capacity batteries to be rapidly charged at currents up to 1.8A with minimum thermal impact when space is at a premium on densely packed PCBs.

The DA9063 supports USB suspend mode operation and for robustness USB power inputs are internally protected against overvoltage conditions. The device’s autonomous power path controller seamlessly detects and manages energy flow between an ADC adapter, USB cable and battery whilst maintaining USB power specification compliance. The internally generated system power rail supports power scenarios such as instant-on with a fully discharged battery. A reverse protected backup battery charger is also integrated into the power path function.

Controlled by a programmable digital power manager all of the DA9063’s 14 user programmable switched/linear regulators may be configured for a variety of start up sequences, levels and timings. For optimal processor energy per task performance, dynamic voltage scaling is permissible on up to five supply domains.

The DA9063 is designed for, and ideally suited for powering the latest generation of portable media and wireless computing applications; packaged in a 169 ball VFBGA 7x7mm package or in a VFBGA 11x11 the device is rated in both consumer and automotive grades.

Putting it in to practice

A good example of a PMIC in action is the power management reference board for Freescale i.MX6 series dual/quad processors. Developed with Freescale ecosystem partner NovTech, the NOVPEK i.MX6 platform evaluation kit allows OEM’s to rapidly bring designs to market based on the i.MX6 series processors.

The quad buck subsystem powers the i.MX6 series system-on-chip and peripherals including external memories, WLAN, Bluetooth, GPS, FM receivers and modems on a 200mm² size PCB.

The use of a configurable PMIC in this case has delivered multiple settings for each peripheral voltage rail, programmable control for multiple power-on events and an accurate power consumption analysis framework to cut the power consumption of the whole design.

Demand for mobile computing products is rising inexorably. Mobile phones have evolved from ‘wireless telephones’ to complete mobile computing solutions in just a few years. Power performance has become a key issue of this era. Consumers enjoy the freedom and flexibility of WiFi in their domestic and work environments but this places added pressures on battery life, requiring more thought and focus on power supply design.

Third-generation PMIC devices are currently in development. New features that will be added include greater integration of low power audio routing and amplification and OTP devices that can be programmed by the customer, allowing a simple but optimum solution yet providing the flexibility to incorporate late changes in the power tree.

Also, expect to see the inclusion of battery fuel gauges which calculate charge remaining in a battery and maybe estimate how long that battery can continue to provide power under specific operating conditions. As designs become thinner, batteries are becoming smaller yet need increased capacity. The addition of an accurate battery fuel gauge will become vital to make efficient use of battery life. As designers are under pressure to save board space and develop ever thinner devices that include ever more features, the use of PMIC devices looks assured.

Author profile: Dave Blissett is Ismosys’ Smart Energy/Home Automation specialist. He has particular expertise in applications such as Smart Metering, Smart Lighting and wireless sensor systems. Blissett held a number of key management positions at Memec, including Xilinx Product Manager and Atmel Product Manager, before accepting the role as the Group’s first European Product Manager. In 2002 he joined Seiko as European Manager. Four years later he moved back into distribution, joining 2001 Electronic Components as Product Manager for Embedded Products. Before joining Ismosys in January 2011 Blissett briefly served as Marketing Manager for Telegesis, the World’s largest designer and manufacturer of ZigBee Modules. Ismosy is Dialog Semiconductor’s pan-European sales and marketing representative.