Small DC/DCs present full-size design challenges

Why would OEMs consider developing DC/DC converters in-house when it is no easier than designing an AC/DC SMPS, asks Andrew Leake, Dengrove Electronic Components

Few, if any, OEMS today consider it worthwhile to commit precious resources to developing their own AC/DC power supplies. Although clearly more efficient, and usually significantly smaller, than a linear power supply offering comparable performance, modern SMPS (switched mode power supplies) demand specialist design knowledge and can be difficult to get working properly.

Buying in the AC/DC power supply as a ready-made unit makes more sense for OEMs, who will generally concede that they do not have the expertise in-house to bring up their own design.

More confident at board level

Nearer the PoL (point of load), however, attitudes can be rather different. Maybe the design of a DC/DC PoL is considered to be a board-level challenge and therefore within the remit of the in-house design engineer. Maybe engineers are simply braver when it comes to taking on such a small and low-power circuit. Another key attraction, often too tempting to ignore, is the lure of trimming a few pennies from the bill of materials, by building with discretes rather than sourcing a module.

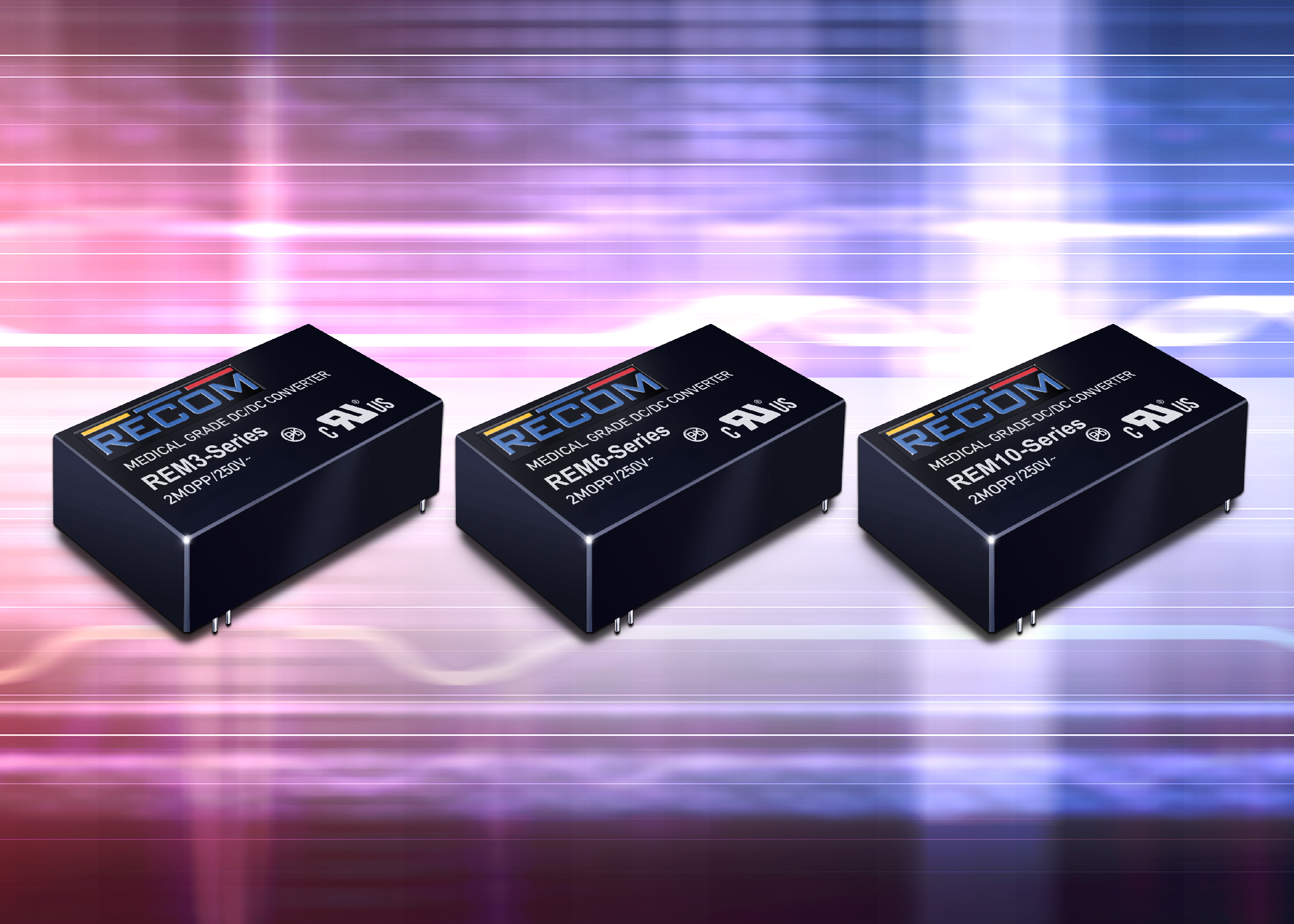

Figure 1: Medical-grade DC/DC converters from Recom, the REM3, REM6 and REM10 series, available through Dengrove and offer 3.0, 6.0 and 10W output respectively in a DIP24 case

Of course, the bill of materials represents only part of the overall cost of producing original equipment. Project managers should always view potential savings very carefully, and consider any likely effects on development costs and time to market. These can have a far more significant impact on the success of the product.

Designing a DC/DC converter in-house carries significant risk. A reasonable time-frame to complete the design is 10 working-days, but still the quality of the result is not guaranteed. Although schematically quite simple - containing only a couple of MOSFETs at most, a controller and a few passives - there are numerous complicated dependencies and interactions that are difficult for non-specialist designers to visualise. No discrete converter is likely to work first time, and subsequent optimisation of the design is also challenging.

Specialist DC/DC module manufacturer, Recom, invests 80% of development time optimising the performance of each design and proving reliability. It is unlikely an in-house team will be able to lavish so much attention on this one aspect of the board. As a result, performance - particularly in terms of efficiency - may be well below expectations. Whereas a typical commercial module may achieve efficiency as high as 90% or sometimes more, we have seen some converters designed in-house achieve as little as 40 to 50%. This can have serious disadvantages, such as demanding bulky and expensive extra cooling, or shortening battery life.

Things to consider

The temptation to save the cost of a module remains strong. Here are some cost implications to consider:

- The cost of employing an engineer with the necessary power experience and the man-hours required for the project;

- If the project is delayed as the engineers get the DC/DC working. A two-week delay could be a conservative estimate and would delay production and lost revenues;

- The associated loss of profit could easily wipe out any cost savings achieved by keeping the design in-house. Worse could be to come, however. If a competitor managed to reach the market first with a similar product, because of the delay, the resulting losses may never be recovered.

There is a good reason that OEMs do not design AC/DC switchers. The same underlying reasons are valid when it comes to on-board DC/DC PoL converters. Independent distributor, Dengrove, has a large selection of high-quality Recom DC/DC modules, covering a variety of I/O voltages and ratings. These are available off-the-shelf and offering guaranteed performance. It is a case of “Design in. Move on”, says the company. There is no need to take the risk to develop in-house.

PIC CAPTION:

Medical-grade DC/DC converters from Recom, the REM3, REM6 and REM10 series, available through Dengrove and offer 3.0, 6.0 and 10W output respectively in a DIP24 case