The connected industry and the Internet of Things that really matter - Part I

Whether it’s called the Industrial Internet of Things (IIoT) or Industry 4.0, the sensing, communication and analysis of data toward improving processes and outcomes is transforming industries from manufacturing and healthcare to transportation, fleet management, mining and agriculture.

While much of the attention has been place on acquiring as much raw data as possible, then analysing it and presenting it to key decision makers, a shift in emphasis is now a foot in that the location and time of data acquisition is becoming just as important as secure communication and the data itself. This shift in emphasis toward more ‘context rich’ data presents exciting opportunities for application developers and system designers in IoT application arenas.

For example, instead of simply detecting a dangerous bump or pothole in the road using tire pressure or suspension monitoring sensors, the data can be combined and communicated with precise location data so other trucks in a fleet can avoid that spot and avert fleet‑wide damage.

Already many basic aspects of a fleet’s vehicle are being monitored using electronic logging devices (ELDs). Parameters of importance include mileage, location, stops, engine usage and hours of service. With pressure, gas and temperature sensors being integrated into tires and engine control units (ECUs) to track variables such as vibration, humidity, and exhaust gases, the overall health of a vehicle can now be monitored in real time. This allows for predictive maintenance, versus catastrophic failure. The main difference here of course is the need to track that vehicle using precise location technology and secure data communication.

This requirement for precision takes on a whole new meaning as the fleet management and human transportation industries look more closely at semi‑autonomous or fully autonomous vehicles. These will reduce or eliminate the need for human intervention, with the prospect of fewer accidents and more economical transportation systems.

In agriculture, the industrial IoT can help secure the global food supply. With an expected 9.1 billion global inhabitants by 2050, using connected sensors to track temperature, soil conditions, sunlight and humidity, can provide the data needed to ensure optimal use of land. Then accurate location services and timely information communication can guide harvesters to ensure those crops are harvested quickly and efficiently at the optimum time.

In a medical application, the exact location and time of a patient’s fall or incidence of increased blood pressure or heart arrhythmia can be used to correlate that to activities to paint a more accurate picture of the patient’s health. Fast and timely communication is equally important; such as in cases of patient status updates in emergency services. In a city‑wide power distribution network, real‑time communication with information around the ‘where and when’ of a switch failure is critical to identifying the original source of a problem, as one failure can lead to a chain of events that make it difficult to identify the origin of the problem.

Extending beyond the manufacturing plant, the health monitoring analogy applies to manufactured goods too. By real‑time communication, that is tracking where and when a device failed, and combining that information with temperature, humidity, vibration and other contextual parameters, a clear analysis of product usage and failure modes can be derived, and fed back into the design requirements for the next, improved, iteration of a device or system. This has the potential to improve overall quality, lower cost of manufacturing and improve the user experience.

Of course, the potential of all this is lost if the data, time and location are inaccurate or haven’t been communicated due to poorly implemented, unreliable, high‑latency, and insecure systems and communications interfaces and networks. Inaccuracies and high latencies of 150 milliseconds or more may be tolerable for consumer gadgets and in home networks, but for industry, maximum performance, ruggedness, security and reliability are critical.

This need for position accuracy down to the centimetre level and timing accuracy into the microsecond range must also align with the always‑present requirement for ultra‑low power consumption. In addition, the ruggedness, noise immunity, security, and high temperature tolerance all the way from -40 to 105˚C for automotive (AEC‑Q100) applications must be met.

This need for accuracy has driven various standards bodies and innovators to re-examine how global navigation satellite services (GNSS) like GPS, BeiDou and GLONASS, short‑range wireless and cellular technologies can be used together to provide the most accurate time and position information possible.

Techniques such as angle of arrival (AoA) and angle of departure (AoD) analysis on Bluetooth signals and time of flight analysis and fingerprinting of Wi‑Fi networks using access point signals are currently in the works, while ultra-wideband (UWB) signalling is regaining traction to also help with location determination.

Cellular is going through its own diversification. Until recently the focus was on higher data rates to address the needs of multimedia applications, but now there is also an emphasis on Narrowband IoT (NB‑IoT) to enable indoor and outdoor, low‑power sensor communications in licensed bands.

Furthermore, the overall architecture of an IoT network is being re-examined. Where once it was believed that separate, sometimes costly gateway devices were required to bring these disparate networks together with smart sensors, it turns out that smartphones, which already have sensors fused with Bluetooth low energy, WiFi, NFC, and cellular communications capability, may well suffice in many applications. If implemented correctly, they may also have many of the security features required for a trusted gateway device.

Many of the techniques for acquiring accurate time and location are still being studied and developed, but designers need to think hard and quickly about how to incorporate them as the opportunity in industrial IoT is rapidly rising, giving clear incentive to get this contextual data paradigm right.

Research firm MarketandMarkets predicted that the industrial IoT (IIoT) market will grow at a compound annual growth rate (CAGR) of 8.03% between 2015 and 2020, at which point it will be worth $151bn.

While the report points to the advances in semiconductors, cloud computing, the standardisation of IPv6 and global governmental support as being key drivers, those are more accurately described as enabling factors. The real driver is manufacturing, which the report shows has largest share of the IIoT market, for many of the factory automation and control reasons outlined above.

Areas that will be prime beneficiaries of the smart factory include product lifecycle management (PLM), electronics, materials and mining, field instruments and machine vision.

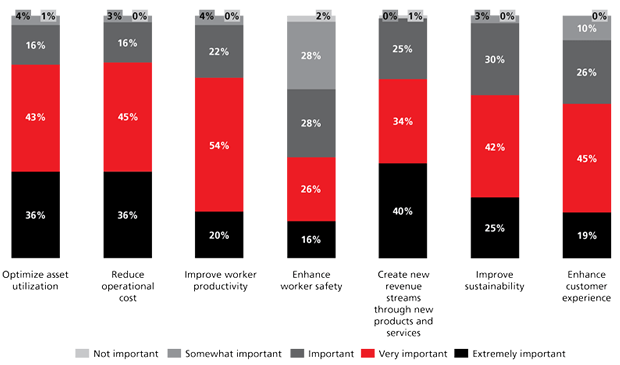

Reduced operational costs, improved productivity, and the potential for new revenue streams, are but three of the many reasons the industrial IoT has fired the imagination of designers and businesses alike.

According to the report, for most incumbent manufacturers, energy companies, agricultural producers and healthcare providers, the initial business case to justify the adoption of IoT have to do with the savings and improvement already outlined, along with potentially driving new revenue streams and enhancing worker productivity and working conditions. In particular, it cites the use of UAVs to inspect pipelines, as well as minimising worker exposure to hazardous environments.

In healthcare, IoT is ideal in networked medical devices, all the way from triage in the field and in‑home medical device wearables to in‑hospital monitoring and rapid‑response drug delivery systems; IoT can improve patient care while also making better use of hospital resources.

By Simon Glassman, Senior Principal Strategic Partnerships, u-blox and Mats Andersson, Senior Director Technology, Product Center Short Range Radio, u-blox.