Continuous coil wires enable epilepsy control brain implant

Epilepsy, a neurological condition that causes repeated seizures also known as fits, can occur in people anywhere and at any time without warning. Neurone cells use electrical impulses to communicate with each other and during a fit, the electrical impulses in the brain are disrupted.

Epilepsy can be caused by brain damage originated in a difficult birth, a severe blow to the head, a stroke, or an infection of the brain such as meningitis. In some cases, the cause is a brain tumour. Here Mike Ford, Business Development Manager at Molex subsidiary Temp-Flex discusses a how the condition can be controlled more efficiently.

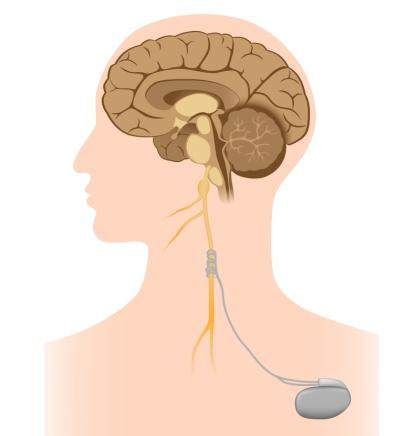

Around five people in every 100 will have an epileptic seizure at some time in their life. Out of these five people, around four will go on to develop epilepsy. However, to help control the condition, Molex is using Temp-Flex MediSpec micro-extrusion continuous coil wires for epilepsy control brain implant.

Temp-Flex, a relatively recent acquisition for Molex, is making a big push into the medical market. Molex won the business because the Temp-Flex coil has high precision tension control that does not damage the insulation. The result was a lead that flexed without failure less often than that of the competition.

Biocompatibility

The precision extrusion process to manufacture Temp-Flex micro-extrusion primary wires used in the coiling process, ensures uniform insulation wall thickness and accurate concentricity. Precious metals, MP35N, silver plated copper and stainless steel wires are encapsulated within a consistent wall coating. Temp-Flex claim that the resulting pinhole-free wire offers greater reliability over similar products with emulsion and dispersion coatings, which are susceptible to cracking. The chemically inert insulation is impervious to surgical fluids and ensures biocompatibility in the human body.

Continuous coil leads facilitate brain stimulation by implanting a 4 MIL Platinum/Iridium conductor coated with.8 MILS of ethylene tetrafluoroethylene (ETFE), then coiling it over a retractable core to form a high flex lead body. Building on Temp-Flex’s prior success in implants for neurological pain management and stimulation, and for pacemaker and defibrillator cardiac rhythm management, it has also been successfully employed for minimally invasive catheter operations.

Key features of the Temp-Flex coil product line include a continuous length characteristic with a tightly controlled lay length. The dense package down to 0.010” (0.254mm) outside diameter has a stacked tolerance ± 0.001” (0.025mm). Tolerance stacks are used in mechanical engineering problem solving for calculating the accumulated variation allowed by specified dimensions and tolerances.

Coiled leads are electrical wires wrapped around a mandrel and designed with a high dielectric withstanding voltage of 500VAC. Benchmark benefits include a retractable mandrel and optional ETFE inner liner tube. Conductors are made up from one to eight filars with optional insulation and ETFE, Polyurethane or Perfluoroalkoxy (PFA) jacket. MediSpec micro-miniature coils (MMCs) deliver stimulation, ablation, diagnostics and pacing with extreme precision in virtually unlimited lengths, meeting requirements for minimally invasive (less than 30 days in body) and implantable (more than 30 days in body) medical applications.

The form factor and degree of precision are required for medical OEMs integrating these into high diligence Class 3 probes and devices. These are highly regulated high risk life support or life sustaining medical devices like pacemakers and neurostimulation devices approved by the US Food and Drug Administration (FDA) for use in humans.

With the options of one to eight filars helically wound around a mandrel, which can be retracted leaving a lumen (tube), MediSpec MMCs allow medical OEMs to tailor application designs to their own requirements. For example, the OEM terminates the coil to the device. The coil is fed through the body to the point of stimulation, ablation, diagnostics and pacing.

Precision requirements

Continuous length coils allow for longer length coils not limited by conventional lathe-based technology. This ensures a more cost effective process and a higher density package with stacked tolerances down to 0.025mm, which meets the precision requirements for invasive and implanted applications. Helically wound micro-gauge coils, using a superior tension control design, delivers an extremely flexible coil for routing coils within the body, allowing paths for multiple media forms including cameras, ablations, fluids and air. This extends the insulation material life of the coil.

Multiple primary wire and jacket filar materials are offered including ETFE, PFA, polyurethane and others upon request, providing a selection of materials suitable for invasive and implanted applications. Primary wire, coil jacket and mandrel lumen are available in biocompatible grade material for invasive and implantable applications.