Shaping the future of industrial designs with GaN technology

Power management is integral to business strategy at Texas Instruments (TI), and the company is pushing significant investment towards GaN technology (gallium nitride), which has huge potential to make a difference to how industrial and other applications are going to function in the future.

Steve Tom, Product Line Manager, GaN High Voltage Power at TI, commented: “If you’re going to innovate and push the envelope of electronics, whether that’s embedded processing or signal processing, it’s really important that your power supply is also innovative.”

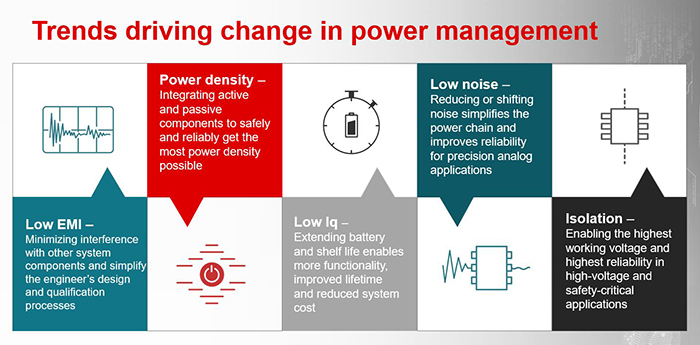

Tom added that there are five key trends driving change in power electronics which are really moving the needle in terms of innovating power supplies. The first is low EMI - minimising interference with other system components and simplifying the engineer’s design and qualification processes.

“This is something that has historically been done through passive filters, but if ICs can add value here, it will greatly improve design ability and overall system performance. A lot of TI’s focus is on this area.”

A second trend, which is pretty self-evident, is power density – integrating active and passive components to safely and reliably get the most power density possible. This is all about making power supplies smaller, while also making them more efficient.

Tom explained that there are several ways in which TI approaches this - one is by integrating the passive components into the integrated circuit, making some a multi-chip module or integrated system. The second is switching faster to reduce the size of components that are not in the IC – a solution that is particularly relevant for GaN.

The third trend is low IQ or bias power. This is also a critical area as more devices (particularly low power) are powered by battery. Looking at the world of IoT, there are many sensors available, and systems that have to run off a battery for a long time. However, they are not systems that are simply turned on and off and still have to be monitoring certain parameters. “The more you can minimise the power drawn, the longer the batteries will last, and the better install your devices will have,” Tom added.

Trend number four is low noise. Tom added that a system is only going to be as good as the worst component on the board, stating: “You can buy the best A-to-D, D-to-A products, but if you don't have the right power supply, with low noise powering it, you are not going to get the full performance from your signal chain. So, reducing noise and being able to have high precision power is critical.”

The final trend is isolation, and this becomes more important as voltages and system electronics become distributed across an environment - especially an industrial system, where there is going to be high voltage, noise, and ground bounce, and those systems are going to be connected to very precision low voltage analogue circuits.

It is therefore very important to isolate these systems for performance and safety (where you could have a human interface). These trends are pushing the envelope and enabling TI to drive innovation in its power supplies.

Why do we need better, smarter, higher density power supplies?

We are far more connected today than we were just ten years ago, and with that connectivity has come a need for power electronics with expanded capabilities that can meet that increase in the demand for power consumption. And, in turn, the need for distributed power management is becoming more critical than ever.

Toms added: “One example that always resonates with me is in the home. You have a lot of systems that traditionally never required power electronics. Now, as renewables become more critical (solar power for example), you need to be able to store that energy through a battery, and be able to connect back into the grid – it is an evolving system that will have higher requirements over time, and we will need more power electronics to cope.

“The same applies to electric vehicles, telecoms and 5G - as these systems have enabled us to become more connected, the power management landscape has changed rapidly and needs to evolve in order to enable those differentiated solutions.”

What does this mean for components?

All this has resulted in three key trends that are driving next generation systems. Toms added that when comparing an RFQ (request for quotation) for a next generation versus a traditional system, the growing requirement is leaning towards shrinking form factors and an increase in performance.

Likewise, now that we are all carrying around devices with many semiconductors, it is important that they work and have long term reliability, and so requirements for increased robustness are also increasing rapidly.

“The challenge going forward is that often these factors will have a trade-off between them that has to be mitigated and managed. Therefore, there are a lot of opportunities related to power electronics that have the potential to really push this forward.

Enter GaN

Gallium Nitride (GaN) is a high-performance switching FET. Traditionally the industry has employed MOSFETs and IGBTs, the workhorses of power supplies, which process the power, typically in switching electronics, which drop or increase voltage.

Tom added: “GaN is a new semiconductor technology. It is constructed very differently from silicon, from the point of view of device physics. It has figures of merits that are often times an order of magnitude better than silicon. And that allows much better efficiency of power density across the board.”

Working with GaN is not without its challenges however, as Tom continued: “The potential for GaN is incredible, but with any technology that is switching faster and harder, it is going to have unique challenges that need to be addressed, understood and put into place. And that’s really where TI steps in. Our decision to get involved with GaN is based around the fact that we have a lot of capabilities in terms of managing noise, EMI, and isolation, that can really allow people to get the most out of GaN from a performance standpoint.”

The pillars of TI’s strategy

Tom added that GaN really is a game-changing technology for power electronics, which is able to take that workhorse energy, and process it faster and more efficiently. He added that the key capabilities of TI’s GaN offering is the industry’s fastest switching speed >150V/ns and >2MHz; and lowest losses and overshoot. TI’s GaN portfolio is also self-protected against extreme surge, current and temperature conditions; provides >30M reliability hours; and <1 FIT over a ten year lifetime.

He continued: “What we do is unique in terms of industry progression over the past several years. We have built our own GaN FET, and with that we are packaging a silicon driver, so that we can get the higher performance out of the device, maximise reliability and the supply chain. We want to be twice as fast and have half the losses. And if you are going to invest in a new technology for a switching FET, you want to be able to get the highest efficiency and the best performance.”

TI have integrated the driver to increase performance, but Tom added that an additional benefit of putting a silicon driver with your GaN FET is that you can self-protect against short circuit and overcurrent. “The voltage is very robust in terms of surge capability, and we have on-chip current over temperature protection, in case a circuit were to get hot,” he continued.

As part of its expanded portfolio TI has done a tremendous amount of lifetime testing - over 30 million device hours, and has been concentrating on driving and owning its supply chain and system costs. “This is something that was important from the very beginning - we developed our own GaN FET internally in our own fab. This means that we own all of our capacity, quality and reliability and this will help us drive down costs over time.”

TI’s full portfolio is now in production, named the LMG3410. The portfolio includes 150mΩ, 70mΩ, and 50mΩ, and allows TI to cover a wide range of power, from 65W type adapters, all the way up to 10kW and beyond for larger industrial systems.

Application focus

Arianna Rajabi, Product Manager, GaN High Voltage Power, picked up the story and offered some further details around the industrial markets where GaN is really pushing the envelope in terms of innovation.

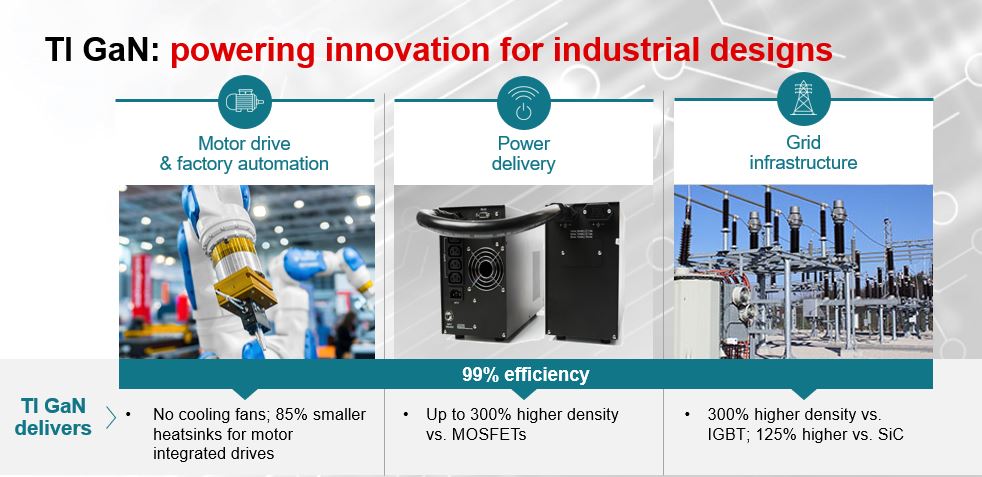

The first is motor drive in factory automation and the increasing need for efficiency in those processes. The demand for factory automation is increasing, and engineers are being challenged to increase the performance of robotics.

A robotic system today will typically have a number of external drives, cabling, and external electronics that would power each of the robot’s motors - so if you have a six axis motor, for example, there are six external drives.

This takes up a lot of factory floor space, so people are beginning to turn to GaN to increase the efficiency of the inverter. GaN can enable 99% efficiency in inverters due to the inherent characteristics of GaN technology, but it can also eliminate cooling fans in these robotic systems.

“Traditionally you would have cooling fans to counteract the low efficiency of the silicon content in the semiconductors, but with GaN, since you can eliminate that fan, you can completely change the way these robotic systems work,” Rajabi added.

She added that by eliminating the external drive, the drives can be brought inside of the manipulator or the robotic arm. When you take a traditional IGBT-based servo drive which has been the norm for the past decade, and compare it with a GaN-based inverter, the GaN version can integrate the drive, reducing 85% of the heat sinking in the system.

Rajabi added: “TI’s integrated GaN-based motor driver has a very narrow heatsink and can actually operate at 99.2% efficiency with quite a small form factor, so this is now starting to replace all of those external drives. With reduced power and communication cabling also comes a lot of cost savings, so the industry is really motivated to follow this integrated motor drive trend.”

Furthermore, power delivery designs are constantly striving for higher power density while increasing efficiency. For example, in server and telecom applications, very high efficiency is needed to meet standards like 80 PLUS Titanium. Silicon technologies cannot meet these requirements, and in almost every case GaN provides 99% efficient PFCs; DC/DC converters capable of switching at MHz range; and planar magnetics for the shortest Z dimension (height) possible.

“In many cases customers would like to increase power in the same form factor of previous generations or past designs,” Rajabi continued. “In other cases they are trying to maintain the same power level and actually shrink the size of the solution. One interesting trend that is emerging in the market, particularly for those consumer applications, is the height, (the Z dimension of the power supply) which is getting smaller, and if you can reduce the vertical dimension of the power supply, it can actually completely change the way electronics look today.”

She added that the Z dimension is typically driven by the height of the magnetics. So if you can achieve the megahertz switching range that GaN can provide, you can move into something like planar transformers, which can drive the height of the entire semiconductor content in the board for these power supplies, and the shortest possible Z height.

A further market application highlighted by Rajabi is grid infrastructure. For grid-tiered power applications, efficiency, size and cost are all important. Increased efficiency in these systems is very critical to limit power consumption. While power levels are increasing, design footprints are trying to stay the same. Previously, IGBTs were used, but with poor efficiency and power density. While SiC has enabled better power density and efficiency, it comes with a higher cost. She highlighted that GaN is able to achieve the best power density and efficiency – while having a lower cost than SiC.

In these types of application GaN can enable multi-level topologies for high density designs; 99% efficiency in completely air-cooled designs; three-phase grid and >900VDC bus; and scalable solutions.