The benefits of module-making

Integrated power modules reduce development time and almost eliminate prototyping and debugging costs. Two modules have been introduced by Exar in single QFN packages.

The XR79110 and XR79115 are claimed to be the industry’s first single QFN packaged modules that require a small number of housekeeping resistors and capacitors, and supply output powers of up to 75W at 15A.

Today’s power modules must be small, efficient and, most importantly, offer competitive total acquisition cost when compared either to discrete solutions or other modules available on the market today.

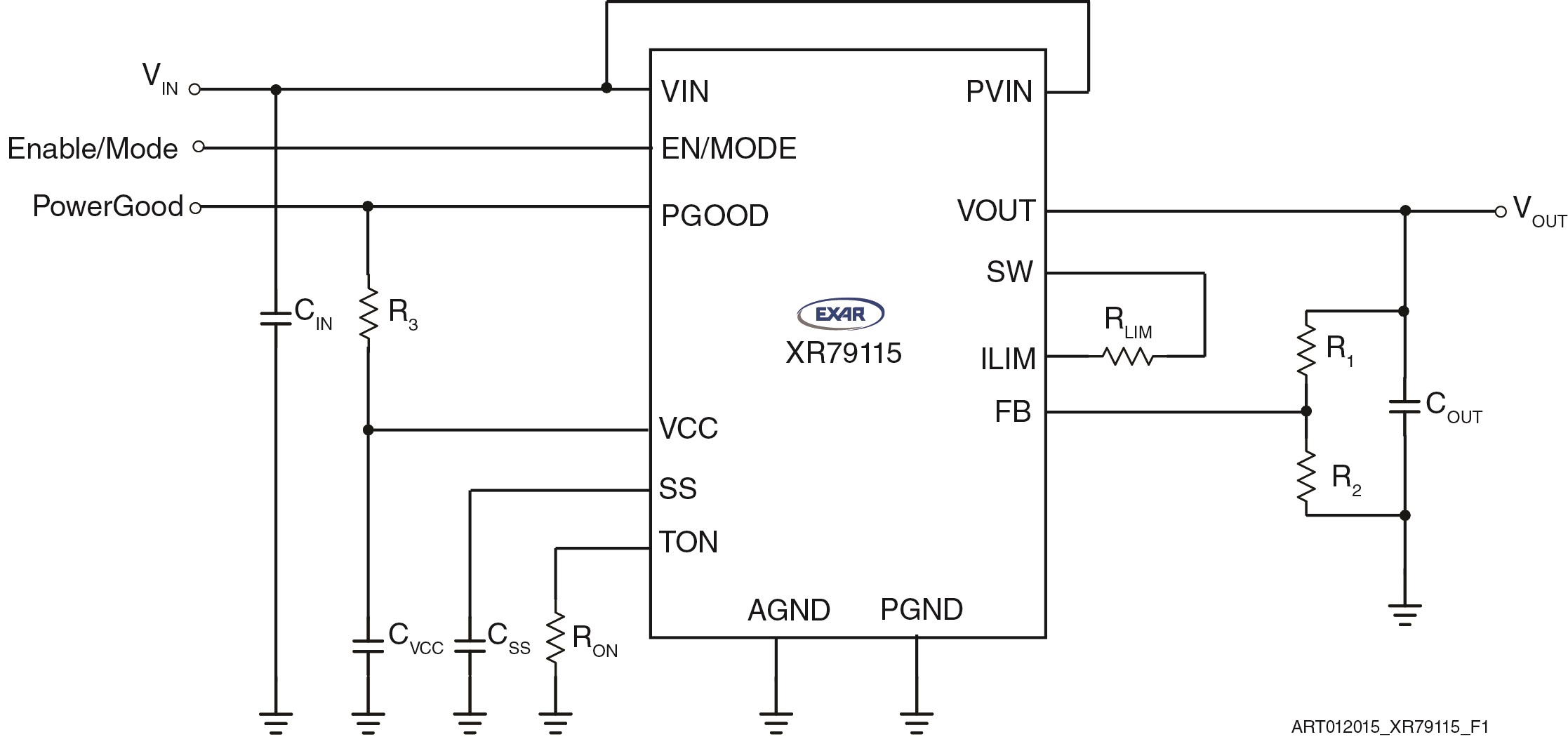

Figure 1 depicts an application example, with few external components. The only ones needed are for setting the output voltage, sequencing and fault management. No external compensation is required if ceramic capacitors are used for the output filter.

Protection features, including over-current, over-temperature, short circuit and UVLO, ensures safe operation under abnormal operating conditions. There is also programmable soft start, programmable hiccup current limit with thermal compensation, precision enable and power–good flag and integrated bootstrap diode.

Constant on-time control

The modules are based on the company’s XRP6141 synchronous step-down controller for point–of–load supplies. The 4.5 to 22V input voltage range allows for single supply operation from industry standard 5.0, 12 and 19.6V rails.

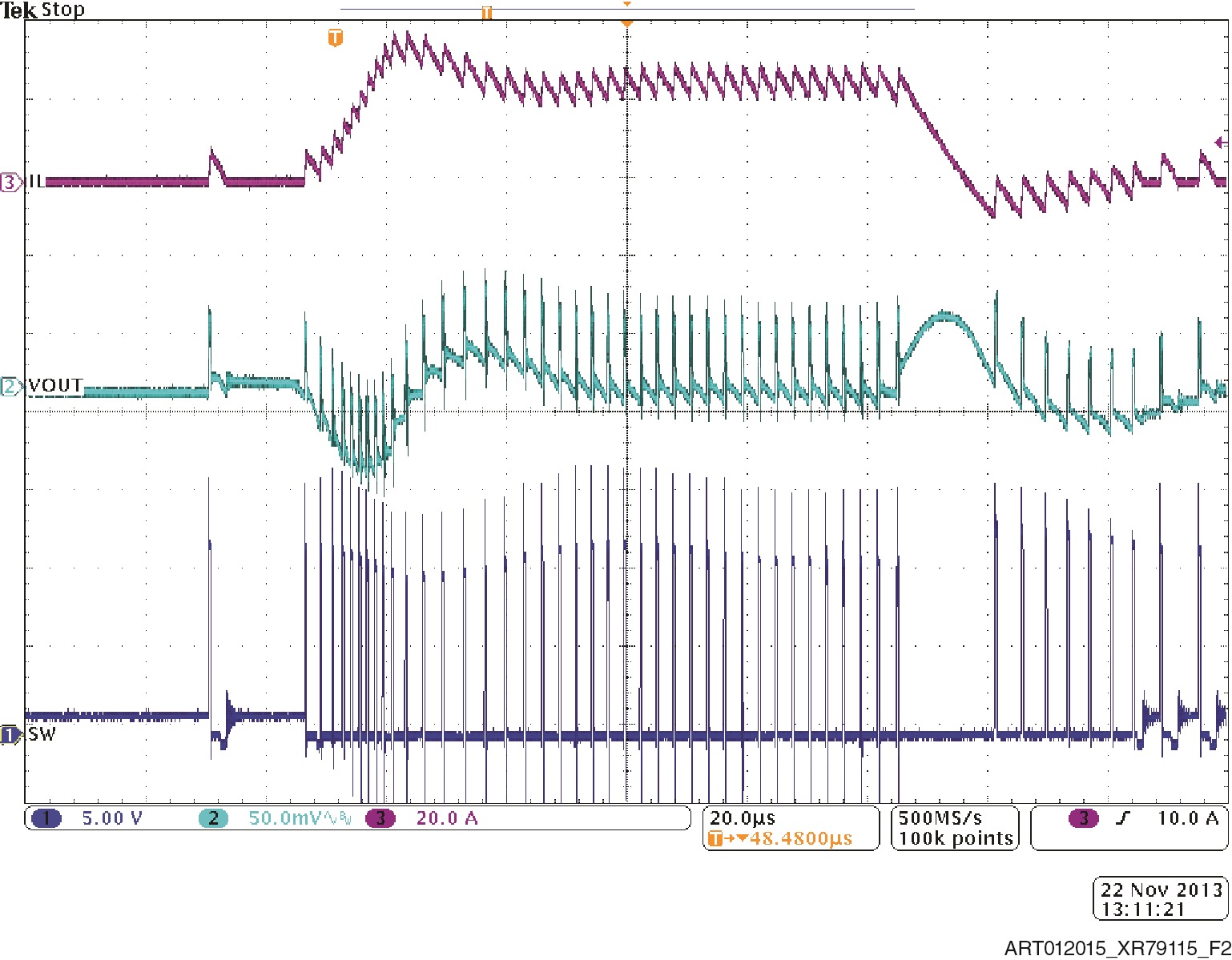

Using a proprietary emulated current mode constant-on time control scheme, the controller provides fast line and load transient response using ceramic output capacitors. The control loop provides line and load regulation and maintains an almost constant operating frequency. No loop compensation is required, which simplifies circuit implementation and reduces the overall component count. A selectable power saving mode allows the user to operate in discontinuous mode during light current loads.

Thermal performance

Both are supplied in QFN packages, offering good thermal and electrical performance, and are easier to debug than LGA and BGA packages when placed on a PCB. According to the company, the 15A, 12V XR79115 package is smaller than anything that exists on the market today.

Packages contain high current pads to optimise thermal performance while minimising EMI. Low thermal resistance from all power dissipating components are linked to corresponding bottom pads for low parasitic inductance and resistance for the high current paths. The 10A XR79110 is supplied in a 10 x 10 x 4mm QFN, and the 15A XR79115 is in a 12 x 12 x 4mm QFN. JEDEC51 package thermal resistance is 18.1°C/Wand 15.4°C/W, respectively.

Figure 1: XR79115 - application example.

The power train

The modules’ power train was designed to achieve the highest possible efficiency over a range of input and output voltages. The XR79115 efficiency for 12V input voltage achieves efficiencies of over 93% at mid-range load currents, and up to 81% at 100mA. Both modules can be made to operate at switching frequencies from 300 to 800kHz.

Figure 2: XR79115 module’s fast transient response from DCM to CCM.