The smaller the better

With demand for ever-smaller portable devices, developments in the design and manufacture of miniature switches can really drive down the physical volume of consumer devices. Jerome Smolinski, Senior Product Manager at C&K Components, explores more in this ES Design magazine article.

Judging by the way some users handle portable consumer electronics, they can be considered suitable for harsh environments. Cell phones, MP3 players, tablets and other portable electronic devices have become ubiquitous personal and professional tools that are used continually throughout the day, and not always with the greatest of care. As a result, switch manufacturers must create new rugged miniature switches that combine significant space and weight reductions with ruggedness and long operating lives. These miniature switches must function in the same reliable, consistent manner as the more substantially-sized industrial designs; yet without sacrificing functionality, performance or extended lifespans. Switch manufacturers that offer value-added services, including manufacturing modules and custom assemblies, are able to deliver complete electromechanical solutions that not only meet the size and performance requirements, but can also withstand the torments of vibration and shock.

Double action switches

Low-profile double action, double-tactile switches are now being designed into handheld and portable electronic devices that require specific ergonomics, such as the focus and shutter release on a digital camera or mobile phone. These advanced double-action, double-tactile switches provide fast, repetitive action in this type of handheld consumer electronics applications. The increased functionality from the miniature double-action, double-tactile switches enables designers to eliminate components from their designs, decreasing the weight and size of their end product.

Some miniature double action, double-tactile switches available on the market today are offered in package sizes as small as 3.7mm x 3.0mm x 0.95mm, including the height of the actuator. Standard pushbutton switches have a typical life cycle of around 30,000 actuations, while typical tactile switches can reach a range of 100,000 and 600,000 actuations; with a target goal of up to 1,000,000 for future tactile switch designs. This long operating life is due in part to a rated resistance to shock and vibration of 10 to 500Hz and an operating temperature of -40˚C to +85˚C.

Pico switches

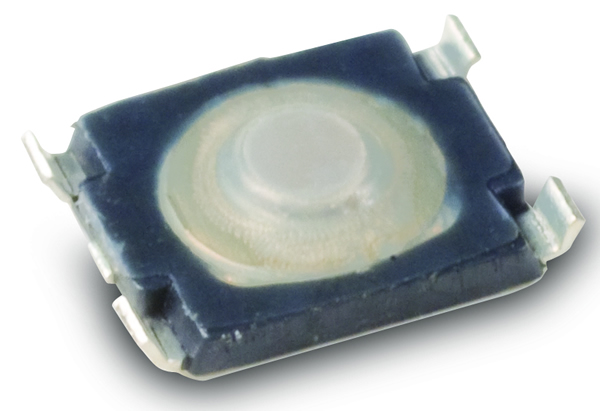

Ultra-miniaturised pico switches improve upon traditional switch designs. Unlike detect switches or pushbuttons, ultra-miniaturised top-actuated pico switches are smaller and more flexible by design. The KXT Series from C&K for example, employs small domes between one and two millimetres within new types of switch structures, representing significant size reductions over nano switches. These truly miniature switches measure 2.2mm x 2.0mm x 0.5mm. A longer version at 2.8mm are also available. Ultra-miniaturised top-actuated pico switches usually provide multiple actuation forces between 1.0N and 2.2N with a 30% tactile minimum. Pico switches also typically provide an operating life of 300,000 cycles with an IP68-rated sealing. The ultra-miniaturised top-actuated pico switches deliver an extended lifespan and rugged design through the use of advanced films and strong redesigned bases, making them an ideal choice for designers working with limited space, but who cannot afford to sacrifice switch or signal quality.

Ultra-miniature pico switches have become increasingly popular for behind-the-ear hearing aids, where all components must be small in size, yet function consistently and effectively. The ultra-miniature top-actuated pico switch helps designers reduce the overall size of the hearing aid, thereby increasing user comfort and reducing the visibility of the device behind the ear.

Pedometers also benefit from switch miniaturisation through a reduction in the overall weight and assembly of the wrist portable version. The pedometer have to work under harsh conditions and keep working for a high number of actuations, making reliability the top concern when considering a new switch design.

The KMT0 Series switches from C&K Components are designed with sealing Teflon films and adhesives to prevent the ingress of fluids, and provide maximum reliability

Tactile switches are inherently smaller and more flexible than many other switch technologies. These types of switches afford the capability of multiple mounting and actuation configurations, providing greater flexibility along with the ability to configure the switch for application-specific needs. Typical tactile switches can reach a range of 100,000 and 600,000 actuations, respectively, with a target goal of up to 1,000,000 for future tactile switch designs. Their long operating life is due in part to a resistance to shock and vibration of 10 to 500Hz and an operating temperature of -40˚C to +85˚C.

Scroll switches are a popular solution in shrinking electronics because of their miniaturised packaging and rugged functionality. Scroll switches typically maintain longer lifespans than pushbutton switches because there are fewer aspects of the switch that can be compromised due to tactile interference. Scroll switches typically feature life cycles of more than one million central select actuations and one million rotation actuations (each direction), with a maximum contact resistance of 300mΩ and inherently strong shock and vibration protection, whereas conventional switch designs can typically only reach 200,000 cycles.

Designed specifically for applications where height or surface area are restricted, sub-miniature slide switches combine a low-profile with an extended electrical and mechanical life. Available in glass-filled housings with 4/6 nylon (UL94V-2) actuators, these sub-miniature slide switches feature a stainless steel cover and return spring to allow for a 100,000-cycle standard lifespan. Measuring as small as 2.6mm by 7.6mm, the surface-mount switches are ideal for a range of applications, including on/off touch screens, handheld games, remote controls and instrumentation applications.

Side-actuated DIP switches combine miniaturisation and high-reliability for logic switching within computers. The DIP switches’ combination of numerous mounting options and a low board-mounted profile increases available PCB space and offers a uniquely flexible solution for design engineers. These half-pitch DIP switches feature a dual bifurcated wiping action that ensures reliable contact. When mounted horizontally, the side-actuation mechanism provides visual confirmation of the on/off status, ideal for logic switching grids where multiple signal paths must be manually routed via switchboards.

These miniature DIP switches measure as little as 4.16mm above the PC board and feature a 1.28mm layout pitch. Process-sealed for surface mount wash processing, the device features gold over nickel over copper alloy contacts and a UL 94V-0 PPS flame retardant housing.

Modules and assemblies

To provide a complete solution, switch manufacturers can also design and manufacture modules and assemblies that meet customer-specific application requirements. Switch manufacturers with engineering expertise can quickly and efficiently integrate switches and electronics (from simple to complex circuitry) into attractive and functional packages that assemble neatly into customers’ finished products. These value-added services can also include manufacturing inserts and injection moulded parts, stamped parts and lead frames to provide a one-stop-shop for customers.

Advanced switch manufacturers can not only refine a switch’s sound (tunability), feel (haptics), and control (interface) within assemblies and modules to suit customer preferences, but also offer a wide range of additional build options, including decoration, lighting, connections and sealing. Incorporating custom graphics, logos, textures and finishes onto critical surfaces also provide a benefit to the end product. Using two-shot moulding, paint and laser etch, pad printing, and plating, these decorative solutions are designed to stand out and fit easily into a portable device, such as an iPhone or iPad. Lighting options include backlight accenting and light piping to enhance a product’s appearance and practicality to a design.

Miniaturiszation and reliability are two of the more important considerations in the consumer device market today. The development of innovative miniature switches has helped enable design engineers to continue this trend. Because electrical and mechanical specifications in consumer applications are critical — tolerances are extremely tight and product profiles are small, and development cycles and lead time requirements are short — switch manufacturers that not only develop flexible and reliable devices, but also add value by manufacturing modules and assemblies, are at a distinct advantage for design wins.