Demand for smaller & cheaper mixed signal technology

The demand for smaller and cheaper mixed-signal technology is growing. Steve Rogerson looks at how the industry is rising to the challenge.

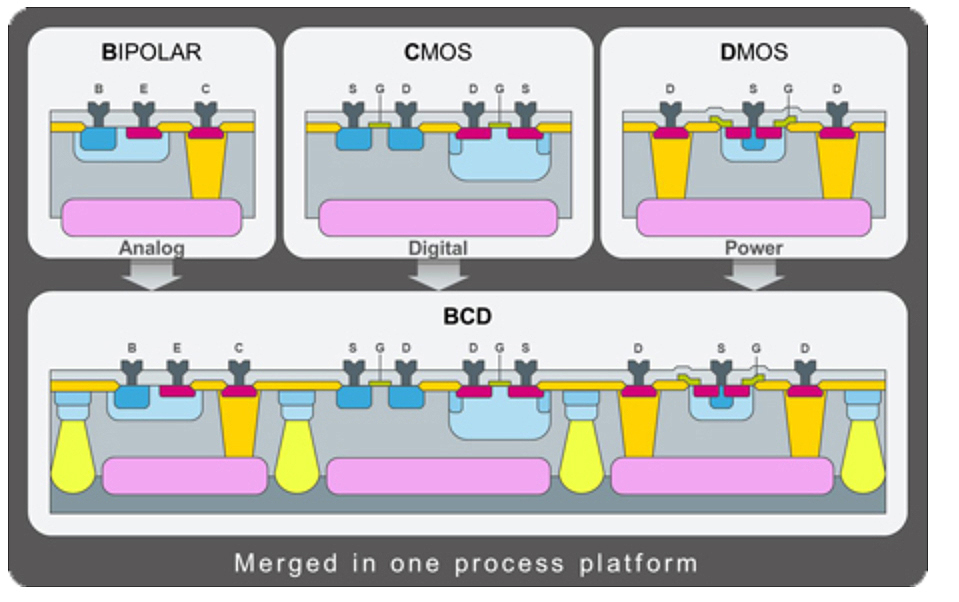

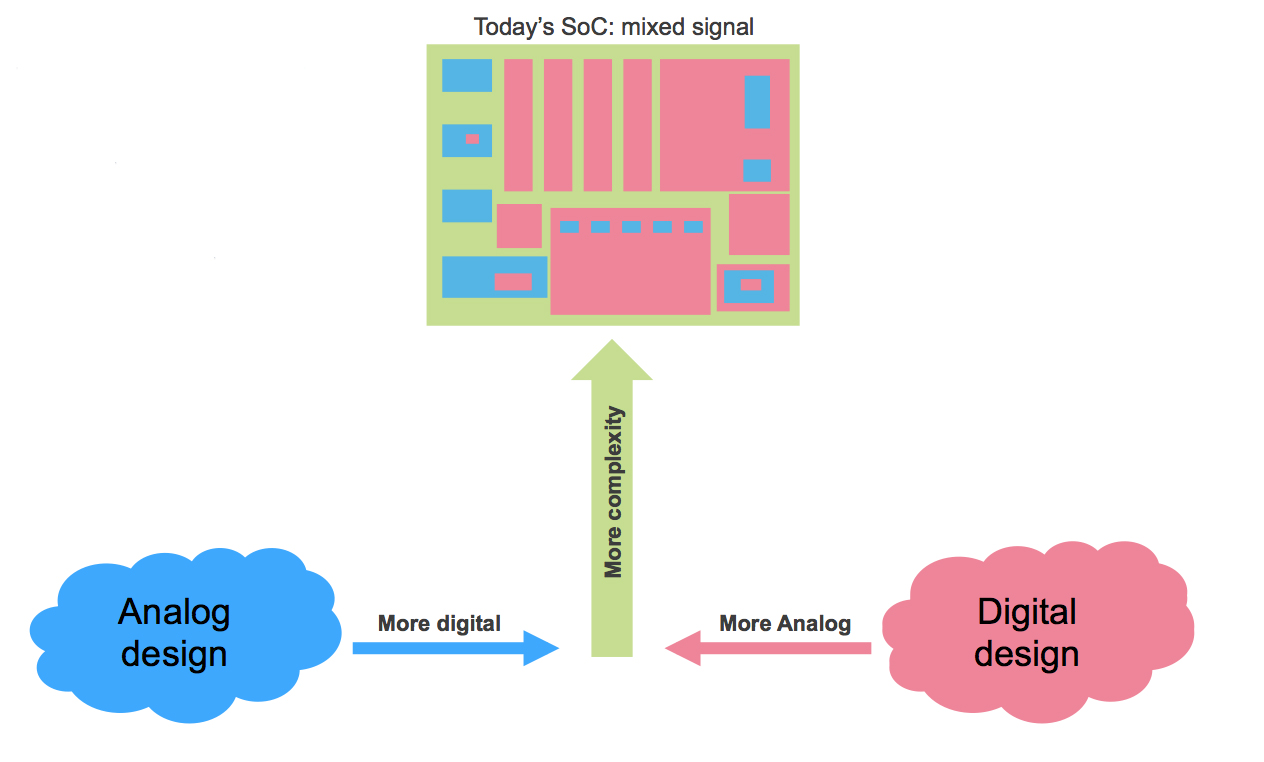

The quest for smaller and smaller devices, particularly in the mobile and IoT world, is driving a demand for integrated circuits that combine multiple processes in one device, be it analogue, power, digital or a combination thereof. This is posing technical problems for the chip makers but, almost surprisingly these days, in some companies cultural problems remain; the divide between analogue and digital engineers still exists. The result has been an increased demand for analogue engineers who are willing to work across both domains, especially given the richness in functionality that can be provided by combining processes on a single die.

Among the biggest drivers of this are, of course, smart phones, as well as the emerging IoT and wearables market(s). For many IoT and wearable applications, there is not a lot of computing power needed but they do require sensors that are bringing in analogue signals: “The key advantage is that it reduces the area on the final board,” said Giuseppe Croce, Technical Line Manager, ST Microelectronics. “You have one device that embeds all the functions.”

There is also a gain in terms of reliability because the connections are etched in, rather than on a PCB. “If the technology can combine most of the elements, you can reduce two or three ICs to one,” said Manuel Alves, Product Line Manager, Freescale. “You have space savings and you can save costs on manufacturing and testing.”

Bringing it all together: How ST Microelectronics combines multiple processes

The technical difficulties potentially impeding include the fact that as geometries become smaller, analogue just does not scale as well: “The physics doesn’t shrink the same way for analogue,” said John Weil, Vice President of Marketing at Cypress, “So you end up with a situation where it can be more cost effective to have an analogue die and a digital die to get the performance you need.” Steve Carlson, Group Director at Cadence, added: “Analogue has more sensitivity to problems when you go down to the real small geometries. This means we are seeing digitally corrected and compensated analogue. In other words, don’t worry about the analogue, just let the digital fix it.”

The other result of this is that mixed signal chips are often a couple of geometries behind pure digital ICs.

In IoT and wearables, the noise has to be kept down as the signals tend to be small and again digital compensation plays a role. There are also multiple power domains at work, with memory working at different voltages to the sensors, and these require new disciplines. “You can’t just put the same old cells on the lower voltage,” said Carlson. “You have to redesign the cells.”

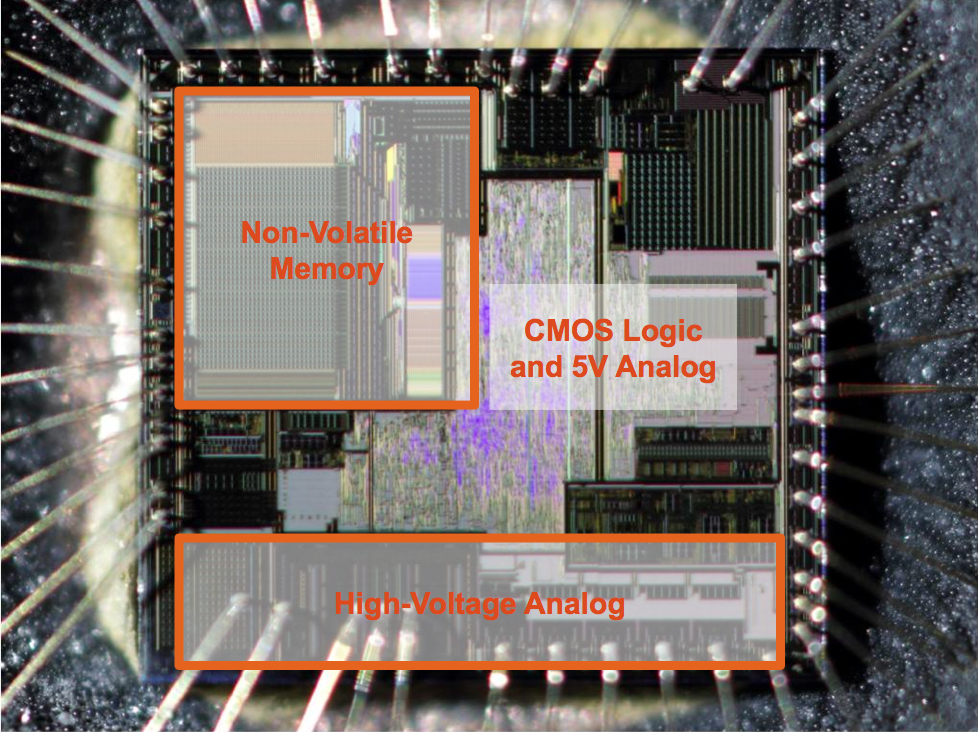

There can be crosstalk issues between the high voltages and the more sensitive memory, which means isolation techniques have to be used between the different parts of the IC. So the main challenge is ensuring that the features of one process do not adversely affect the other processes. This, said Croce, often involved a compromise, usually because of cost reasons: “Theoretically, it should be possible to do everything,” he said. “You should be able to merge the processes but the cost can explode. You need to simplify the process complexity, so compromises are needed and that is the main challenge.”

There has to be a good balance for mixed-signals chips to be cost effective

Alves agreed: “It is not straightforward to combine technologies,” he said. “There is R&D effort to do this. With people and money, you can always solve the problem. You need to find the right balance."

Weil believes the way to handle it is to start with the most advanced of the processes and then look to integrate the other processes into that: “You anchor on the most advanced technology,” he said. “Then you think about the other technologies. The processor guys think gate count per square millimetre, the processor guy looks at layers and added flash, the radio guy wants good RF that also has integrated flash. These don’t always go hand in hand.” This is why earlier radio models used different dies in the same package, though progress has now been made on integrating flash and RF and it can be done cost effectively.

“Things like Bluetooth and Zigbee can be integrated on the same die as flash, but if you move to high performance RF such as high-speed WiFi and cellular, you are still better putting that on a separate die,” said Weil. This is just one area where using multiple chips is still the sensible way to go. “It is a matter of what level of performance you are looking for,” said Croce. “In applications where PCB area is a key factor, a single chip is probably the best. This includes mobile, where size can’t explode. But there are plenty of areas where reliability is a key factor, such as in automotive.”

Also, it depends on the balance between analogue and digital. If the IC is going to be 90% logic, then it is not really worth the design effort to combine analogue; they might as well be put on a separate die. “It would not be worth trying,” said Alves. “You need a balanced mix of features. Integration is not great for all products.” That is why Weil believes a lot of the problems can be solved with packaging technology with more than one die put together at a chip-scale level. “Rather than try to integrate the technologies on chips, use chip-scale packaging to find creative ways to put them together,” he said.

Culture

“The real difficulty is bringing together the separate cultures that there are between analogue and digital designers,” said Carlson. “They have to work closely together.” The wearables market has cracked this divide open again, believes Weil: “Analogue had become a forgotten art,” he said. “There wasn’t an end demand for more complex mixed signal technology. The wearables market is changing that. It is pushing the boundaries of low-power analogue.”

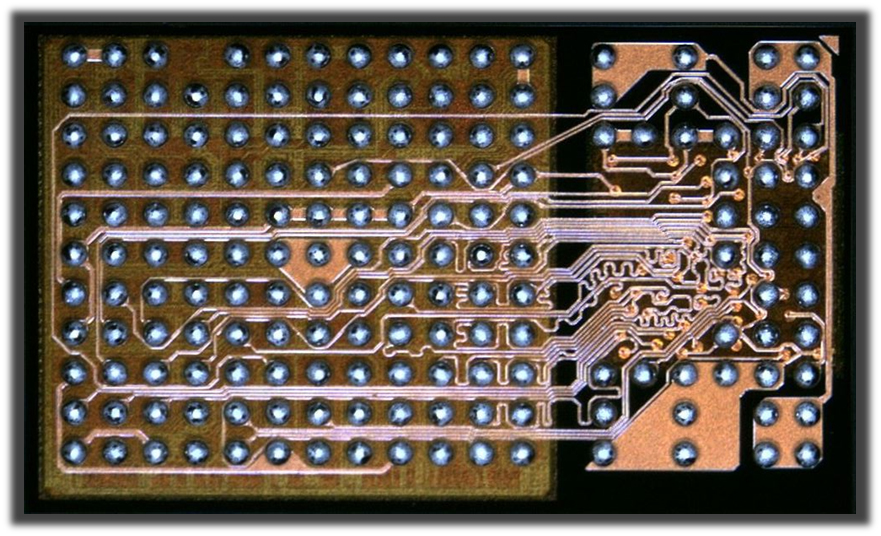

Integration on a Cypress M series chip

There are varying styles of multi-discipline approach, but Carlson found that in most cases the disciplines work separately: “They partition the problem,” he said. “Analogue is here and digital is there. But as you push down the process nodes, you need to move them together and be able to handle the resultant complexity.” This, he said, meant there were digital tasks that the analogue guys had to learn, many of which were new concepts for them. “The divide still exists but we are seeing more job advertisements for mixed signal engineers,” he said. “You have to change the ‘divide and conquer’ concept; you introduce the digital to the analogue world and have to manage the culture.”

Weil added: “The culture barrier is still there. You go in one day and you talk to the analogue guys and then you talk to the digital guys and they don’t really care. The analogue guys are into the nitty-gritty of the design. Every time that is integrated, they have to give up a little bit of turf.” A classic case of this, he said, was what happened with glucose meters; what was once very complex for measuring the chemical reaction is now relatively trivial.

Croce believed the way to go is to recruit good engineers and train them internally: “There are a lot of good engineers,” he said. “We recruit smart engineers and we have a strong internal training process.” But he said there was nothing wrong with having engineers within the team who were strong in just one area provided they worked as part of the team: “We do have some who specialise in digital or analogue,” he said, “but they have to think about what they are doing when this is put together with other parts.”

Test & verification

Design is not the only problem when it comes to mixed signals. The test and verification phases also have to work across both domains. “You need people to understand both sides of the fence,” said Carlson. “By and large, the analogue and digital designers can do what they do without learning too much of each other. But when the design comes up for verification, that is where they really need to learn about the other side.” Here, he said, it was important to find someone with a multiple domain background who could oversee the process. Some companies do simply dictate that the analogue team design must work with digital in mind, but that does not always come out well.

How Freescale puts it all together

“The most successful,” he said, “is when you have the mixed signal experience. The analogue guys are not used to thinking about breaking up the test sequence. They just have one Spice model and add as they go along. They are not very good at partitioning things up.” The advantage of combining everything on one chip when it comes to testing is that there are fewer test points and you also reduce the number of test instruments needed. “For us internally, it creates some challenges for testing the IC functions,” said Alves, “but the end user will have less to test.”

The IoT and particularly the wearables market is driving new research into mixed-signal technologies to achieve both the size and the cost needed for what is shaping up to be a mass market. But some R&D departments are still suffering from old divisions and these need to be resolved if the companies are to capitalise on the latest wave.