Why the microWatt/MHz MCU is the low-energy king

In the world of the low-energy application, the microWatt/MHz MCU is king.

By Philip Ling, Editor, ES Design magazine.

Generally speaking, embedded solutions are defined by one of two overriding parameters; high performance, or low energy. Ideally they wouldn’t be mutually exclusive and for some applications they aren’t. It’s all relative, after all. But for the billions of IoT nodes in development, expected to operate for many years from a single battery, low energy takes priority. Fortunately, performance in these applications isn’t expected to be demanding; a core running in the low MHz should provide more than enough processing power to meet the majority of requirements, such as periodically servicing sensors and sporadically communicating with a local hub. As a result, many manufacturers are now laser-focused on developing MCUs with the lowest active and static power credentials.

The architecture of choice, for many, is ARM’s Cortex-M family; in particular, the diminutive Cortex-M0+ has found favour with many manufacturers, as it offers the best power/performance trade-off. It may seem odd, therefore, for a manufacturer to choose the comparatively thirsty Cortex-M4F when launching a new MCU targeting ultra-low energy applications, but that’s exactly what Ambiq Micro has done with Apollo; the company’s first MCU family based on its proprietary Sub-threshold Power Optimised Technology (SPOT) platform. Initial claims are bold; compared to other Cortex-M4 based MCUs from Atmel and STMicro it promises between three and ten times lower active power respectively, and as much as 28 times better sleep mode power than the STM32F401. The differences in these figures for competitor devices based on the Cortex-M0+ are smaller but still better, and no less impressive for it, so how does it do it?

SPOT on

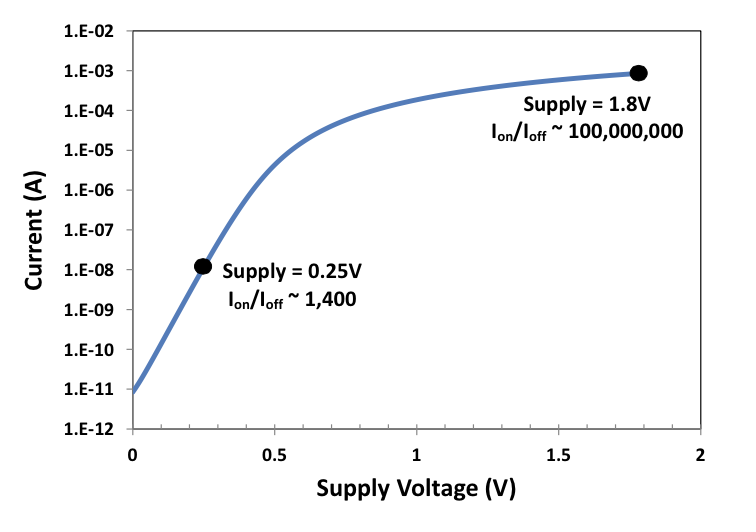

The key to the power savings is the theory behind SPOT; by keeping transistor switching excursions below the thresholds normally used for switching, the power represented by the area under the curve is significantly reduced (Figure 1). It’s a technique that’s been around for many decades but more recently Ambiq’s founders were part of an academic team working on its revival at the University of Michigan, before spinning it out in to a commercial company.

Figure 1 - the reality of power curves

According to Mike Salas, Vice President of Marketing, Ambiq Micro and ex-Vice President & General Manager, Microcontroller division, Silicon Lab, almost all of the Apollo uses the SPOT platform (the only parts not built on SPOT are the Flash and RAM), which is manufactured on a standard CMOS process but did require new transistor models and cell libraries to implement. Salas commented: “There’s nothing exotic about the technology itself, it was clearly important that we do this on standard CMOS.” This makes it a little less transferable, but not impossible.

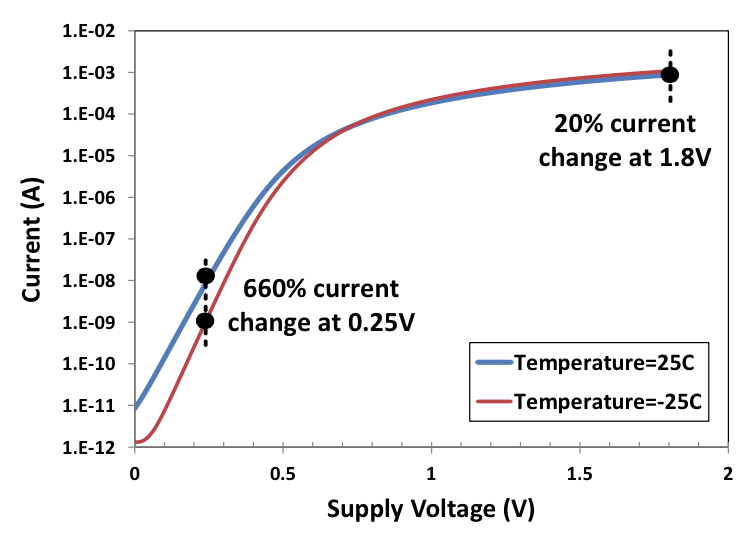

The circuitry required to detect the lower thresholds and combat the ‘bad things’ that can happen at lower voltages is Ambiq’s patented technology and, although it does introduce an overhead in terms of silicon area, Salas claimed it’s modest; around 5%. Some of those ‘bad things’ relate to the impact process and environmental variations can have at the transistors level; the voltage threshold can vary with temperature and the on current depends exponentially on this (Figure 2), which is why the platform’s finer details are patent protected. Salas explained: “Really the Crown Jewels of the company is not so much in our ability to dial the voltage down, but in our ability to create a set of dynamic adaptive circuitry that accounts for and overcomes the bad issues; that’s where all the patents and innovation really exists.”

Figure 2 - process variations can impact energy efficiency

All this can still be used alongside other established techniques used by most if not all MCU manufacturers, such as voltage/frequency scaling, power/clock gating and autonomous peripherals, leading to the impressive results. Salas explained: “We do most of those things, but even though we benefit from the same architectural tricks, it’s because our floor is so much lower than everybody else’s that allows us to develop these incredibly low power numbers.” Salas added that the company plans to release ULPBench results in the near future to substantiate these claims.

What’s the catch?

Ultimately, there is a price to pay for lower energy consumption; V/F scaling illustrates this in ‘conventional’ MCUs and in Apollo it comes in the form of the maximum operating frequency. Salas explained that the SPOT platform is limited by speed, it couldn’t offer a device operating at 1GHz, for example, but he is confident that it could reach 100MHz and beyond. However, the Apollo family has been specified at 24MHz because this is the ‘sweet spot’ for its target applications, such as wearables and the IoT.

Another benefit that Salas was keen to point out was that SPOT allows for optimisation of both active and sleep mode power at the same time; something others need to choose between: “If they want to optimise sleep power they tend to work in an older process node that has very good leakage currents but at the expense of higher dynamic power, or vice versa.” Salas maintains that Ambiq doesn’t have that problem. It also means it doesn’t have to make the decision between a Cortex-M0+ core or M4: “The penalty for us between using an M0 or an M4 is negligible. It makes a lot more sense for us to use an M4 core in these applications.” He was referring to the amount of computation IoT nodes are expected to do now and in the future. It also means that Salas sees no problem with implementing the Cortex-M7 in a future family.

That may happen in the future, the Apollo family is sampling now and scheduled to go in to volume production in the Spring, priced at $1.50 in 10,000 unit volumes. And even though the title of lowest power MCU will be hotly contested even when the Apollo becomes available, developers will still need to weight their demands against the manufacturers claims when it comes to selecting the right part for their application.