The perfect pyramid of automation

A new interpretation of an old solution to understanding the architecture of control systems puts SCADA at its heart, to allow better control and decrease the cost of maintenance by storing and managing all data in a single control room. By Marco Zampolli, HMI Product Sales Manager for Advantech, & Maurice van der Aa, Industrial PC Product Sales Manager, for Advantech.

The pyramid in question was developed over 20 years ago and ever since has been used to classify devices, engineering needs and maintenance requirements — and as the name suggests, the information (data) available and required for the automation of production systems in the manufacturing and process industries. There are five layers to the automation pyramid and it can be divided into two distinct sections: the bottom part of the pyramid is the production process (i.e. sensor actuator hardware and PLC, PC and PID), while the top level refers to the enterprise resource planning systems for business management (i.e. the SCADA network, MES and ERP). Each of the five layers represents functions of a similar type, with different devices such as field bus or Programmable Logic Controllers (PLCs) being strictly allocated to one specific layer.

In line with similar engineering hierarchies the pyramid shape was chosen because of the characteristics of the information on the different levels, such as package data size, transmission frequency, real-time requirements, availability requirements and so on.

The top of the pyramid features the least amount of data; as we go down the amount of data increases, as the amount of information increases.

As information travels up the pyramid the data is condensed. At the bottom, where the sensors and actuators are, information is sent to the control level where they control the production process. The only data sent between the control level to the HMI level is that which the operator needs to be transferred, as such it is less frequently transferred and in bigger packets. At the top of the pyramid, only orders from the business technology infrastructure are transferred to the control level, whereas shift protocols as well as production KPIs are transferred to the business IT.

SCADA and MES

There’s another way to read the pyramid. Levels I and II, at the base, are the building blocks of automation and focus on the hardware, sensors actuators and their controllers. They’re needed but are not enough to constitute a modern automation system. Levels III and IV, in the middle of the pyramid, are the future of automation and represent a significant step forward in automation system training and education.

SCADA (Supervisory Control and Data Acquisition), a term broadly used to portray control and management solutions, allows the control and acquisition of data from various sensors in Water Management Systems, Electric Power, Traffic Signals, Mass Transit Systems, Environmental Control Systems, and Manufacturing Systems. Factories in remote locations send this data to a central computer that is then used to manage and control the equipment to which the sensors are connected.

The computer systems used in manufacturing are known as Manufacturing Execution Systems (MES). The point of MES is that it provides the right information at the right time and shows decision makers how the factory floor can be optimised to improve output. Since MES works in real time it enables the control of multiple elements of the production process.

With MES being the link between Enterprise Resource Planning (ERP) and SCADA it is essential that it is incredibly accurate and reliable. To ensure accuracy, Advantech uses Embedded Server technology with strict revision control, which guarantees a stable platform for a long period of time. Some key features of the server technology are Xeon processors, ECC Memory, RAID hard drives and Redundant Power Supply support. Furthermore, an Intelligent Platform Management Interface (IPMI) is being used to monitor the system in real-time, get alerts and manage the system from a remote location.

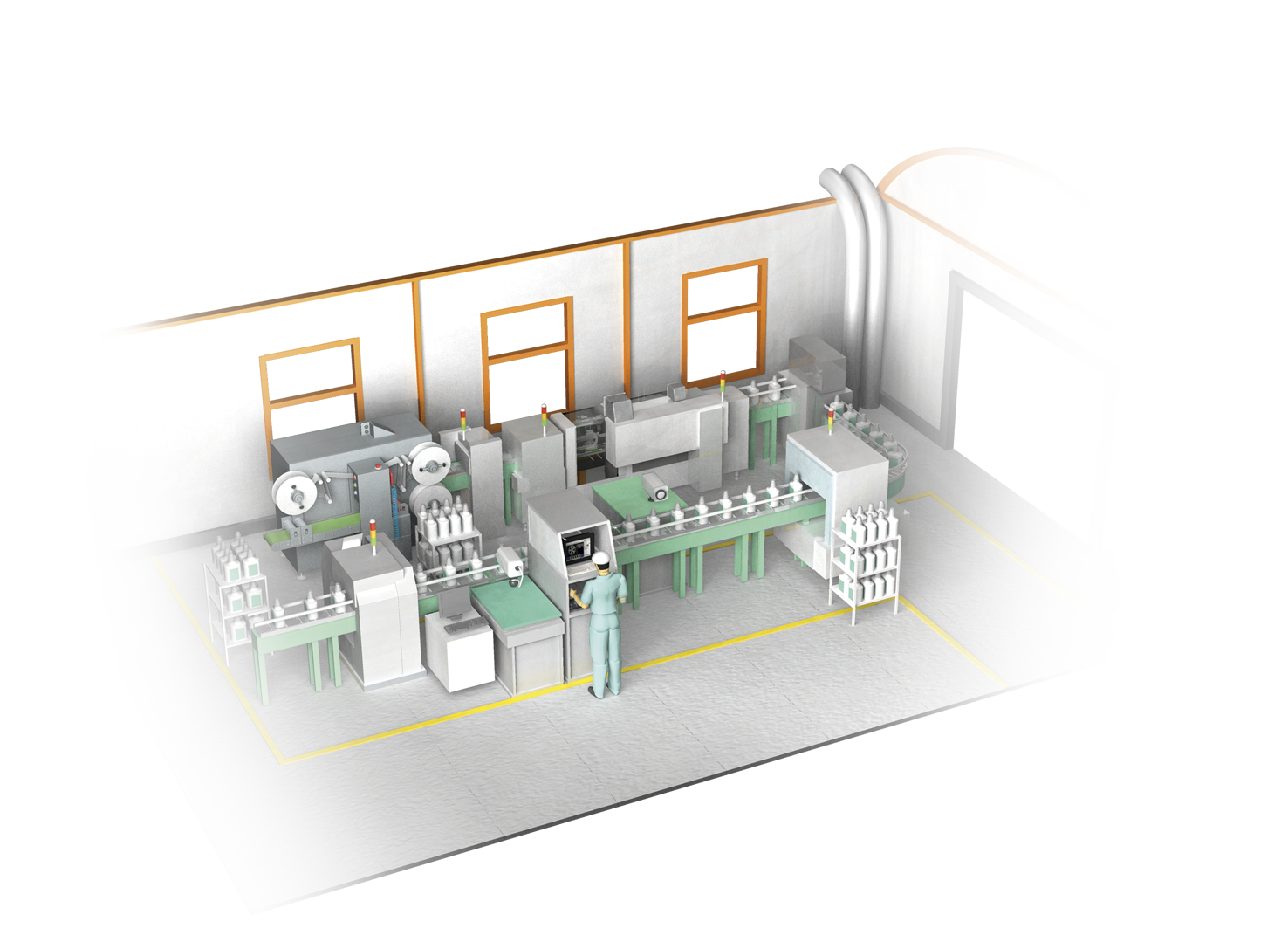

In the bottom layers of the pyramid, a human machine interface (HMI) must be present to allow the exchange of information between machines and operators. By creating a unique Graphical User Interface (GUI) for all the operators in the production line, SCADA systems allow users to perform operations in an efficient and effective way.

The flexibility of SCADA means that users have an almost limitless expandability and engineers can adapt and upgrade their system’s features and capabilities to meet immediate and future requirements.

With the ability to connect and manage thousands of sensors and record vast amounts of data, SCADA systems are powerful, robust and flexible, which enables reports and real-time simulations to be displayed and run from anywhere that offers connection to the system.

Robustness

For industries and environments for which unplanned downtime would be catastrophic, the use of SCADA with its time-proven robustness has been essential for monitoring and controlling the building automation systems.

Since its inception SCADA users have demanded that system developers are able to connect to legacy and dissimilar systems and networks in their plants. This level of openness and integration is especially beneficial for building automation systems where many different manufacturers have equipment installed.

With their ability to integrate with many types of different manufacturers, users are not restricted by the size of the system they start with. The flexibility of SCADA means that systems can start small and grow with the systems needs.

Reporting is essential for engineers to see the status of all the plant and building systems. Through the use of SCADA’s web-browser technology the status of the entire system can be viewed and adjusted from any web-browser including those on a smartphone.

Industrial communication devices are essential for SCADA architecture and it’s important that these devices are reliable, since communication between SCADA systems needs to be transparent and any form of maintenance may have an adverse effect on the entire network.

With a diverse range of plant topologies, SCADA systems need to be both strong yet supple, with the ability to be able to work under a multitude of conditions from extremes of temperature to dust laden air and other conditions that make up a harsh environment. Advantech is able to deliver complete solutions, from operator interfaces, to high computational power IPCs, as well as reliable and transparent communication solutions for the SCADA and MES layers of the pyramid.

With 30 of years experience in providing a full range of products to different vertical markets, the Industrial Automation Group within Advantech is among the leading automation providers, globally. By combining connectivity, flexibility, ruggedness and being at the leading-edge of the Internet of Things technology, IAG offers product solutions like intelligent HMI platforms, industrial Ethernet, wireless communication, automation controllers, automation software, embedded automation computers, distributed I/O modules, wireless sensor network solutions, plug-in I/O, and industrial communication for a wide array of industries.