C what you get

In August 2014, the USB-IF released the specification for the Type C connector for USB 3.1, promising a simpler and more integrated single-cable solution. Steve Rogerson looks at how likely that might be.

Offering 10Gb/s and up to 100W, USB can now be used not just for powering smartphones and the like but for desktop PCs and workstations. The Type C connector is smaller, making it more suitable for thinner devices and more consumer-friendly as it can be inserted any way up. A Type C cable will also have the same connector at each end so it can be plugged in either way. And there are more pins, which means the USB connection can be used for extra applications.

“The real focus for USB is to deliver a single source for audio, video, data and power all over a single cable and connector,” said Jeff Ravencraft, President, USB-IF. “It is bidirectional, it doesn’t matter which way you plug it in and which end you plug in. There is no longer an A and a B. With the Type C connector we have a very robust connection.” The system is backwards compatible but only through the use of dongles to bridge between legacy USB connections and Type C cables, but Ravencraft envisages that eventually the C connector will take over everywhere.

And Gordon Lunn, Global Customer Engineering Support Manager, FTDI Chip, added: “The new Type C connector signalling is fully backward compatible, so engineers looking to make use of it won’t have to rework there designs, they will be able to make use of the same ICs and firmware that they were previously. A full range of conversion cables will be available (B-to-C, A-to-C, etcetera) so implementation of this new interconnect option will be simple enough to accomplish.” But Alan Jermyn, Vice President for European Marketing at Avnet Abacus, said he had been speaking with suppliers and the feedback he was getting suggested they were worried about backwards compatibility issues.

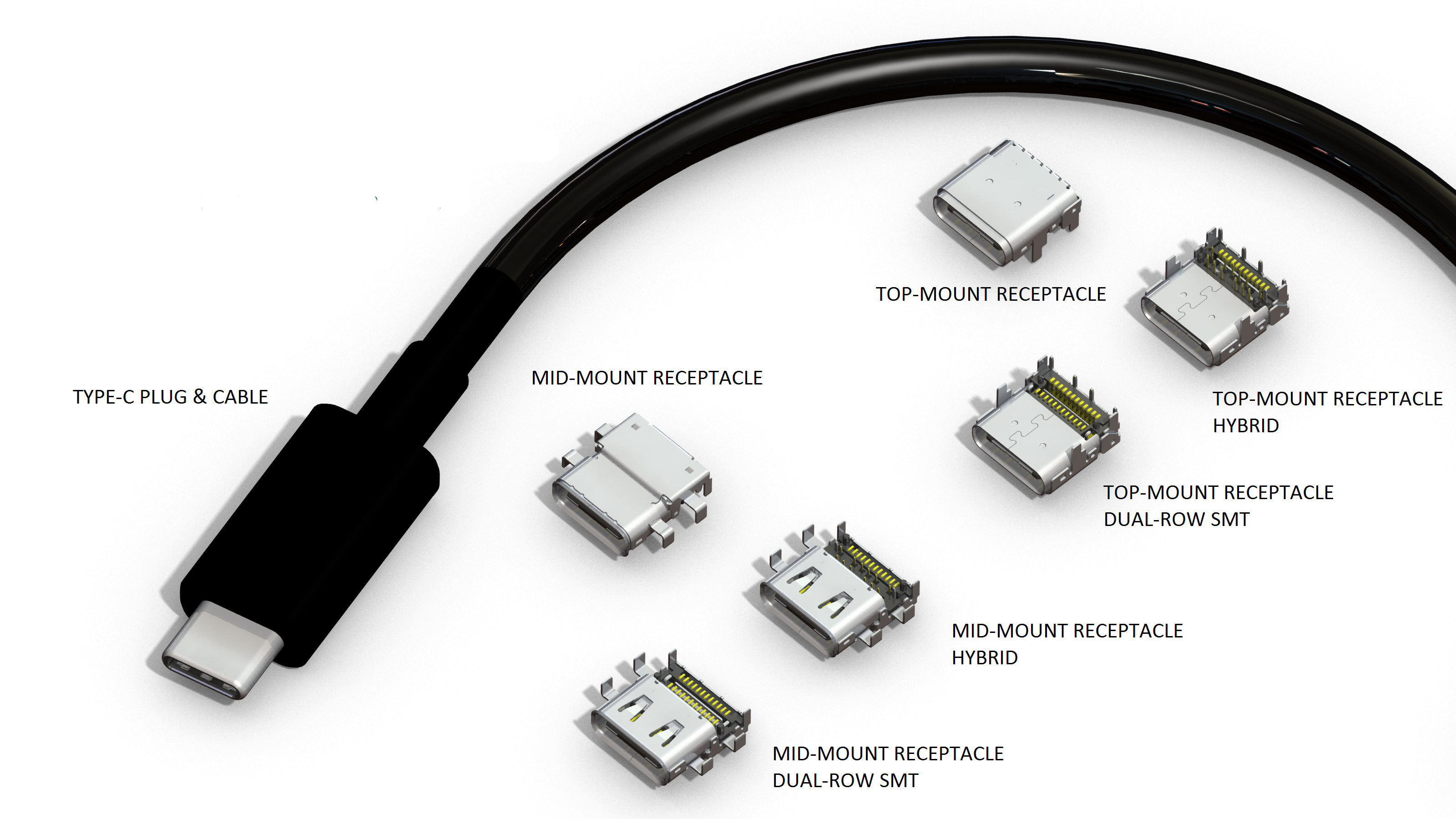

USB Type C connector with receptacles (photo from Foxconn)

“Our engineering team has been monitoring the USB-IF,” he said. “The connector is reversible so it can be plugged in either direction similar to Apple's Lightning connector. It is not backwards compatible with any previous USB connectors, which is why they have specified what looks like nine new cable types each with a different legacy connector attached. The lack of backwards compatibility is a concern. Realistically, they are up to two years out from offering these in production.”

One of the traditional ways to connect multiple devices via USB was to use a hub plugged into the mains. This is now moving to having the hub built into the display, which is connected to the mains. This can then be used not just to connect the other devices but to provide power to them as well. The 100W power delivery is a significant increase over previous versions. USB 2.0, for example, could deliver 500mA and 5V, or 2.5W. With 3.0, this went up to 900mA, or 4.5W. The added battery charging specification boosted this to 7.5W. Data delivery is also twice as fast as USB 3.0’s 5Gb/s and five times more than Hi-Speed USB. Also, the voltage, current and direction of the power flow can be negotiated.

“The direction can be changed in real time,” said Ravencraft. “For example, a netbook would normally be a provider of power and the cell phone connected a consumer of power. But connect the netbook to the display and that could provide power to the netbook. The flow of power can be changed dynamically.” Using the latest power delivery method with the Type C connector also brings extensions beyond power. The most noticeable for most users will be the dual role data transfer. Like the reversible power, the status of host and device can also change dynamically. For example, if a phone and notebook are connected, the phone would be a device, but if you connect the phone to, say, a TV or printer it could become the host.

Alternate modes

The other key change is discovering and configuring what are known as alternate modes. These let vendors run additional features on the connectors, such as PCI Express for example. “The USB-IF is developing guidelines so you can easily recognise the capabilities you are getting,” said Ravencraft.

How this works is that the 3.1 data channels are on one side of the 24-pin connector, and that can be either side depending on which way the connector is inserted. The other side of the connector also has high-speed data pins and it is these that can be used for other purposes.

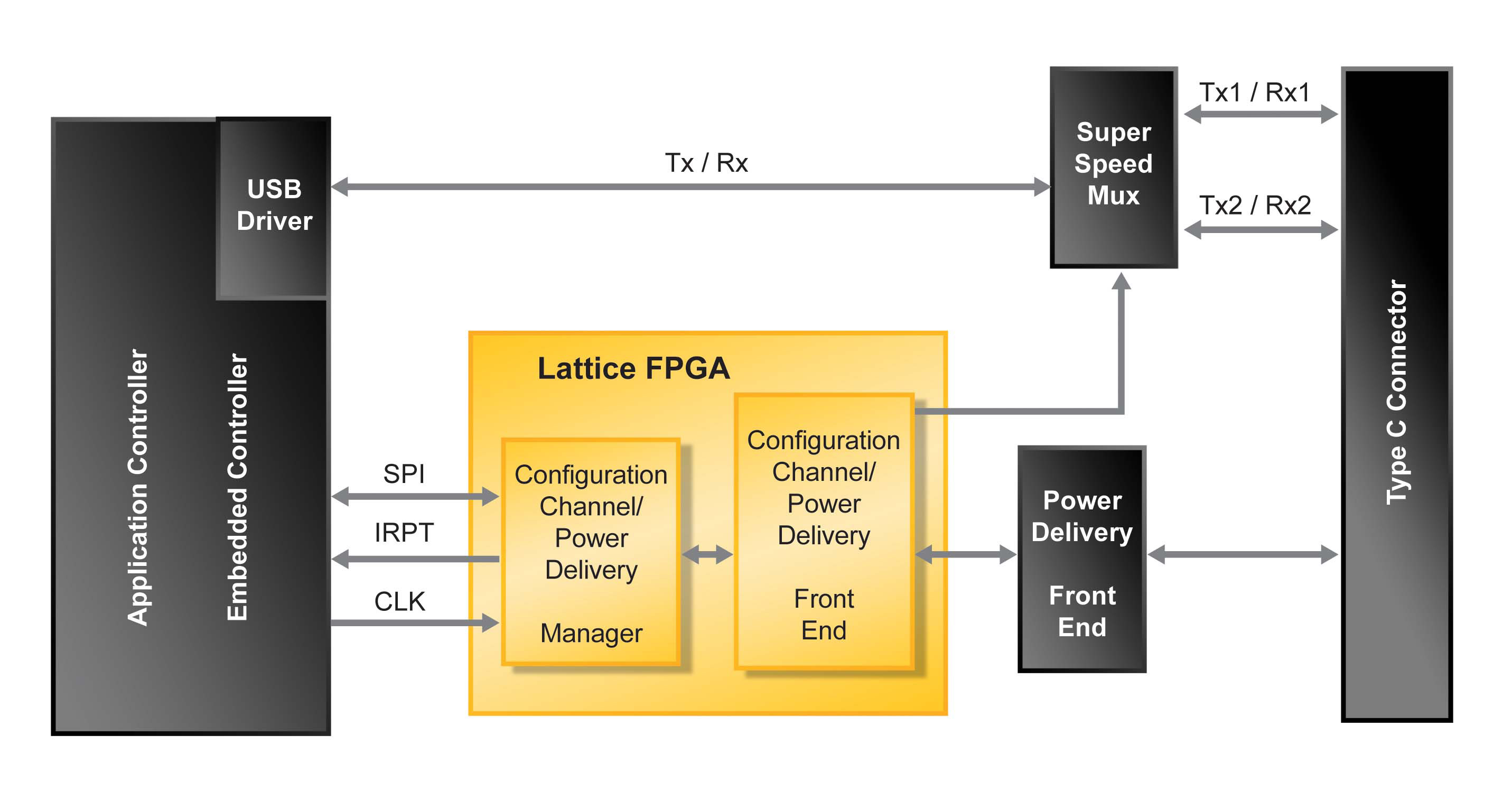

“You could use them to transmit video using embedded DisplayPort,” said Tom Watzka, Technical Marketing Manager, Lattice Semiconductor. “There is a protocol that lets you set this up between the host and the client, but it is a challenge to enable this capability. The specification is very new and there are no solutions that we are aware of. The opportunity is that these specifications are really flexible. This is what is driving the interest. A lot of OEMs see the possibility of using this for their specific needs.”

Not surprisingly, he sees an FPGA route to helping companies handle this flexibility. “With our FPGAs, we have begun development on this,” he said. “Because they are programmable, we have been able to adapt them very quickly. There is a lot of flexibility with the kind of data and that can be used for competitive advantage.”

Tim Wang, Product Marketing Manager, Lattice, also sees FPGAs as a way to handle the other features of Type C: “The FPGA can do all the work,” he said. “It can figure out which is the host and which is the slave. You need to figure out what kind of power the slave requires and the FPGA can do that. And it can do the negotiations with the host.”

How an FPGA can be used to handle the flexibility with the Type C connector

Drivers and dissent

So what were the drivers for these changes? First, the Type A connector was too large for emerging computer platforms; it needed to be thinner. The Micro-AB connector might have been good enough for mobile phones, but it didn’t have the robustness needed for other roles. Also, many consumers were confused with plug orientation and cable direction – trying to force a USB connector into a socket the wrong way up is not uncommon. The Type C connector addresses all these issues.

The specification was finalised in August and was the result of an industry-wide collaboration. “Anybody could participate and help define it,” said Ravencraft. “We are now compiling a compliance and certification programme and we want to have something in place for early 2015. We expect to see products in the market in early 2015.”

However, not everybody is happy. Molex, which already has samples of its Type C connector and is planning product in 2015, is a little worried on the size and cost of the connector. “Initial feedback from the mobile phone makers is that the connector size of Type C is too big,” said Carol Liang, Group Product Manager, Shanghai, Molex. “Connector width and heights are industry standard dimensions but we have generated different proposals to shorten connector depth (24 pins with dual row SMT soldertails or 14 pins with single row of SMT soldertails). The dual row SMT soldertail design, however, may pose inspection and rework concern to mobile phone makers.”

Ravencraft responded: “There was a lot of work put into the size. There had to be give and take. Some wanted it smaller, but we had to ensure the robustness, both mechanical and in terms of shielding for RFI and so on. The industry has agreed on this size. Maybe it could have been a little smaller but I think it is the right size.” Liang also has concerns about cost. “Early indications are that the total solution may cost more than Micro USB 2.0,” she said. Ravencraft responded: “Initially, with new technology there will be a slight price difference. But even from the outset, they will be competitive. But for the long term, with the type of volumes for USB the price will become very inexpensive.”

However, Liang thinks this will only happen with EU support, which she believes is not certain. “The EU has adopted Micro USB 2.0 as the standard IO for charging mobile equipment and this makes the demand on Micro USB 2.0 very high,” she said. “At this early stage the industry is unclear as to whether the EU is going to do the same thing with Type C. If the EU does, we would expect volumes to be high. However, cost pressure will also be high. Hence, we need to design Type C with both low and high volume manufacturing strategy planned out now so that we can be cost competitive down the road should volume demand pick up.”

On the face of it, the Type C connector looks just what the industry has been looking for. It is smaller, easier to use and brings the flexibility for other high data applications. But there is worry that dongles and special cables will be needed to handle the large numbers of equipment with existing USB sockets. And some believe that the size is still too big for modern devices. And, yes, it will cost more and that cost will only come down if the other problems fail to stop widespread adoption.