Life inside the IoT

The world is set to become much smarter over the coming five years. By 2020, some 50 billion electronic devices will be connected to the internet, according to networking specialist Cisco. They will support an estimated $14tr market for distributed intelligence that set to improve not just manufacturing and service efficiency but the quality of life itself. Digi-key explain the impact of the IoT on a variety of industry sectors.

The systems that dominate the internet today, such as PCs, laptops, tablets and smartphones will be dwarfed by the tens of billions of machines with network connections that will relay data to each other with the aim of making life more efficient. By enacting changes in response, the control systems that form part of the IoT can improve efficiency in a wide range of systems, from industrial control through transportation to healthcare. The IoT provides the ability to transform the ways in which services are delivered and bring about massive savings to society.

Healthcare

Healthcare costs are set to rise dramatically as the average age of the global population increases. The proportion of the population of the world aged 65 and over is set to double from a little over seven percent today to more than 15% by the end of the 2030s. The proportion in the developed world will be even higher as life expectancy is already significantly higher than the global average. A key problem for governments around the world is the quality of life of that ageing population. Many will live with chronic medical conditions that require regular treatments and consultations. The result is likely to be a dramatic increase in the cost of healthcare, whether financed by state taxation or insurance costs.

A significant proportion of those costs is due to extended stays in hospital. Costs will come down dramatically if the patient can stay at their home and receive instead a series of brief consultations from a nurse or doctor. However, appropriate medical staff are not always close enough to allow travel to a surgery by a patient. Specialist medical staff work in city hospitals but in a developed nation a quarter of the population will live in rural areas and do not find it easy to travel for consultations.

Using the IoT, sensors can be deployed around the patient’s body and used to monitor vital signs such as heart rate, blood pressure and respiratory rate, sending important data to doctors and nurses to allow them to watch for potential problems. Researchers have also found that in the case of rehabilitation, they get a better sense of the effective mobility of a patient if they can determine how well a patient climbs and descends stairs and gets out of a chair rather than simply walking across a doctor’s surgery.

Wearable IoT goes far beyond treatment of medical conditions. It can help reduce injury and boost wellness. The same IoT technology proposed for medical sensors can be used to prevent injury, such as damage to knees caused by bad posture while exercising. Similar sensors incorporated in a vest could help prevent the poor posture that leads to back pain. In these cases, exercise programmes in a smartphone or tablet can advise interactively on better ways to move.

Transportation and automotive

As well as reporting on health and fitness, sensors will help drivers maintain concentration on the road while driving and help extend their ability to remain independently mobile. Cameras and other sensors will help monitor the driver’s attention, ensuring that the vehicle does not suddenly move out of a lane or altering the driver to situations where they close their eyes too long because of drowsiness.

There are a number of further pressures that drive the motor vehicle into the world of IoT, such as better fuel economy, greater comfort and convenience for the driver and passengers as well as manufacturing efficiencies. For a growing number of automakers, the mobile phone provides the key to differentiation and convenience. Bluetooth connectivity has already been widely adopted to allow the use of phone conversations by the driver but this is likely to be augmented by the increased use of higher bandwidth interfaces such as WiFi.

While connected to the car, apps running in the phone or another connected tablet can help keep the driver updated through the car’s entertainment system on useful information such as nearby filling stations or tourist information. These features could prove to be important differentiators for rental cars as they would allow any car to be personalised to the user the moment they connect their mobile device.

As well as infotainment and connectivity, wireless connectivity can help continue the trend to build increasing intelligence into the car’s core systems, particularly for body electronics systems. As the designers have succeeded in reducing the weight of body panels and the chassis by moving to composite materials, the wiring loom has become the second heaviest single component in the vehicle – behind the engine itself – weighing more than 50kg and comprising several kilometres of copper wiring.

A typical car has up to 60 microcontrollers today, taking in information from a variety of sensors. The number of sensors that can feed important information to in-car control systems is challenging the ability of the wiring harness to keep, providing the impetus to move to wireless-based systems. Wireless communications for safety are already in use through the near-worldwide adoption of the Tyre Pressure Monitoring System (TPMS). In this system, battery powered sensors fitted inside each tyre regularly update a controller in the car body on changes to air pressure inside each tyre so that it can issue a warning if one or more of the tyres is above or below its approved limits.

Pressure sensors extending their reach with designs that can survive inside the vehicle’s cylinder to better measure the exact mix of fuel to air and reporting in real time to distributed controllers to support even more advanced engine management systems.

By using smart wireless devices, it becomes easier for a manufacturer to fit different options without having to account for combinations of wired sensor and actuator interfaces. Instead, the network configures itself as devices start up and register themselves with a command hub that may be wired into the vehicle’s wired networks, such as CAN or Ethernet.

Wi-Fi provides a further benefit to the automaker – during manufacture. Current approaches to firmware updates involve the use of a wired connection to an in-car network based on Ethernet. This demands that the vehicle remains at the uploading and test station for as long as the data transfer and writing to flash memory takes. Very often the limiting factor is the write speed of the different areas of non-volatile memory in the car. By using WiFi instead, uploads to the vehicle can take place while it moves along the production line and other systems and components are fitted.

Industrial control

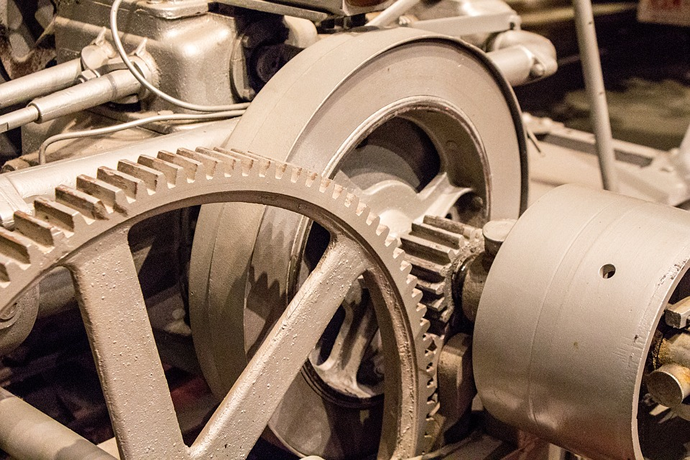

Similar operational efficiency gains will help influence in driving the adoption of IoT technologies by other industrial users. Traditionally, industrial control systems have used discrete automation systems based around centralised controllers. Individual machine tools and similar systems use increasingly sophisticated control algorithms to optimise production and efficiency in each system. The next step is to devolve intelligence out to individual sensors and actuators using IoT technology.

Intelligent mechatronic components, fitted with embedded microprocessor-based controllers, can be fitted to machine tools and other equipment and programmed not just to work together, but be reconfigured more easily. Smart devices, such as valves, motors and pumps can be programmed to run various control algorithms based on the selections made by supervisory controllers, as well as perform diagnostic functions to alert those supervisory systems to potential problems. By moving processing to the machine, it is possible to make the control loops more reactive and increase productivity.

A key advantage of distributed intelligent control is that the system can be upgraded in stages. Controllers that do not need to be changed can maintain their existing programming while others can make use of more advanced algorithms and techniques, as long as they use the same control and communication protocols.

IoT solutions - Communications

There are three fundamental components that combine to form an IoT node: intelligence, sensing and wireless communications. The diverse requirements of IoT applications call for a range of solutions for each of these. For example, The focus on control makes the industrial IoT different than the IoT that consumers will experience in applications such as smart homes and smart healthcare. Industrial IoT nodes will need real time I/O handling and resilience in the event of failures to a communications link or node. Automotive applications require high cost efficiency and consumer applications favour solutions that offer ease of use and greater compatibility with tablets and smartphones.

Implementers of industrial IoT systems have a number of network interfaces to choose from, from IP-enabled Ethernet to wireless protocols that support low overhead versions of IP, such as the family of protocols built on top of the IEEE802.15.4. These include ZigBee and 6LowPAN. Engineers can use programmable transceiver technology, such as that provided by Lime Microsystems, to offer support for a variety of wireless schemes that may be chosen to support a particular implementation. For example, to save on wiring costs for a long pipeline, it may make sense to use a sub-Gigahertz unlicensed band such as 868 Hz, running a version of 6LowPAN but employing the mesh networking capabilities of ZigBee. Mesh networking offers routing resilience in the event of the failure of a single node – other nodes find a way around the breakage by discovering new routes through the mesh.

In industrial systems involving mobile assets, such as robots and warehouse picking systems, the IEEE802.15.4-2011 family of protocols offers support for ultra-wideband communications that can provide position information about the sender as well as sensor data.

For wearable and smart home applications Bluetooth Low Energy (BLE) and Zigbee are key protocols. Given its compatibility with smartphones, BLE has important advantages for wellness devices that are sold to consumers over the counter as well as for more specialised medically oriented devices. BLE is well supported by component manufacturers such as CSR and STMicroelectronics for both sensor devices and monitoring hubs, where BLE is often coupled with WiFi, allowing easy transfer of data to the internet. However, Zigbee has longer range, making it well suited for where sensors need to be integrated in the home and are not just deployed around the body.

Lower latency – just 3ms versus the 100ms of classic Bluetooth – can help propel BLE into automotive applications together with its low complexity –BLE’s software stack can easily be incorporated into lower cost microcontrollers. BLE retains support for frequency hopping from the original Bluetooth protocol, which makes it more robust than Zigbee in the presence of strong interfering signals.

Able to support longer distance communications, Zigbee has been proposed as a potential solution for communication between moving vehicles and roadside data terminals that may transmit data on congestion and other useful travel conditions, collecting data from multiple different types of sensor mounted in vehicles as well as the roadside.

Sensing

To provide the IoT with information about the world around it, sensors are vital and they come in many different forms, although they split into two broad classes that are based on similar physical principles. One class focuses on conditions at a point, measuring chemical concentrations, gas pressure or strain sensors. The other class, based on accelerometers and gyroscopes, analyses motion.

There are several different types of pressure sensor – capacitive, piezoelectric and thermal flow. Capacitive sensors work by detecting the change in capacitance as changes in pressure alter the spacing between a moving plate and a fixed place. To prevent potentially corrosive gases from damaging the micro-machined elements, the moving plate is normally sealed from the environment by a thin, deformable diaphragm.

Piezoelectric pressure sensors work in a similar way to capacitive, again using the deflection of a moving beam or plate to measure pressure. In this case, the piezoelectric coating on the beam registers the force caused by a pressure change as a change in voltage. A variation of the piezoelectric sensor is the bridge-based sensor, which uses strain gauges mounted on a thin silicon diaphragm in a Wheatstone-bridge configuration to register movements caused by pressure changes. The bridge-based sensors tend to be used where there is a high risk of overpressure situations as they can be made highly resilient, suiting them to industrial process control.

An alternative to the strain gauge approach is to sense the changes in heat caused by pressure fluctuations. Some measure the speed of the gas flow as heat that is added to the flow stream disperses. Others measure the temperature difference between a heated sensor and the ambient flow stream. They are relatively inexpensive and can measure the flow of low pressure gases. A further advantage is that they allow for the monitoring of more than one of the characteristics, such as temperature and thermal conductivity, which help to define the actual mass flow rate, although they fare best with a clean gas flow.

Thanks to the massive popularity of the Nintendo Wii and the Apple iPhone, sensors that detect motion have become a major force in MEMS and have become more familiar to end users than pressure sensors. There are two types of motion detecting MEMS sensor in common use - accelerometers, often used to detect linear motion, and gyroscopes, used for sensing changes in orientation.

As with pressure sensors, there are a number of technologies to choose from in accelerometers that include capacitive, piezoelectric and thermal. Both capacitive and piezoelectric motion sensors rely on electrical changes caused by the displacement of a proof mass, which is typically a beam or plate that is partially anchored to allow part of it to move freely. Typically, capacitive devices increase their signal-to-noise ratio with the help of a folded beam structure that contains many moving and fixed finger elements.

Manufacturers of capacitive sensors argue their implementations are less sensitive to temperature changes than piezoelectric because the gaseous dielectrics they employ to separate the moving elements from the fixed plates do not expand much compared to doped silicon under normal operating temperatures. The thermal coefficient of many gases is generally much lower than that of silicon. The capacitive sensors also have the ability to sense DC acceleration as well as vibration. This is harder for piezoelectric systems, which require a dynamic input at a fixed frequency to generate a sensor response.

The MEMS gyroscope presents a further option for motion sensing. Deployment in smartphones has led the way but the sensors are being used increasingly for stability control in automobiles and image stabilisation for cameras. Many devices are single-axis designs – as stability control systems do not need full 3D rotational data. However, integration has made it possible to bring the ability to sense rotational motion in all three axes into one device. This is important for the competitive smartphone and gaming system markets, but also brings the cost of electronic gyroscopes down for organisations developing unmanned aerial and marine vehicles and more advanced robotics.

Inertial sensors in smartphones can be supplemented by magnetometers, where they use measurements of the earth’s magnetic field to provide information on orientation relative to the polar axis. Several magnetic sensing approaches are being used by a number of companies for consumer mobile phones that include Hall effect, giant magnetoresistance, magnetic tunnelling junction and anisotropic magnetoresistance sensing. In contrast to many MEMS designs, they do not use moving parts but apply the micro-machining techniques to form multi-layer magnetic structures that can sense low level fields.

Chemical detectors are becoming increasingly important. However, these remain less commonly used because it is difficult to make them general purpose. In the case of chemicals, the sensor often needs to be tuned for a given type of gas or fluid as many of them rely on the adsorption of molecules on a treated substrate – which changes the mass of a moving beam – to work. However, advances in optics and signal processing are pointing the way towards more general purpose devices that can use spectral analysis to determine the presence of different chemicals in air or water. As technology progresses, we can expect these to be added to the arsenal of MEMS technologies developed for the IoT.

Control

The final step is to integrate communications and sensing into a highly integrated package that, in order to survive for long periods of time on a single battery charge, needs to exhibit low power consumption. Typically, the node will be dormant for long periods of time, waking up for short periods to take a reading and then make a decision on whether to send out an alert based on the change or go back to sleep. A large number of microcontrollers are designed around this core requirement, sporting ultra-low energy sleep modes combined with high performance instruction pipelines to streamline processing while awake.

IoT oriented microcontrollers (MCUs) often incorporate specialised low power support such as hardware state machines that offload much of the real time sensor processing from the core processor itself. This allows the processor to spend much of its time in a low energy sleep mode, only waking up when the peripheral hardware indicates that a sensor has picked up a sudden change in activity or condition. Because a high proportion of time is spent in sleep mode – often higher than 99% – overall energy consumption is kept to a minimum and ensuring longer periods between recharge.

As the IoT scales up, new solutions will appear that increase integration – packing control and sensing into a 3D package as well as incorporating sensor hubs tuned for IoT use that provide further savings in power consumption. However, the three key components of IoT support are already in place to support a host of new applications across industry, healthcare and transportation.